Preparation method of nanometer beta-form titanyl phthalocyanine

A technology of titanyl phthalocyanine and β crystal form, which is applied in the field of preparation of new nano-β crystal titanyl phthalocyanine, can solve the problems of cumbersome post-processing process, long ball milling method, long induction time, etc., and achieves cumbersome post-processing process. , The effect of long ball milling time and more loss of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0022] (1) Prepare 1 g of TiOPc particles by vacuum freeze-drying and sol-gel method with the synthesized TiOPc;

[0023] (2) Put 1g of TiOPc particles into a tube furnace with a hydrogen atmosphere, raise it to 300°C at 15°C / min, and keep it warm for 1.5h;

[0024] (3) Quenching with liquid nitrogen to drop below 0°C instantaneously, to obtain β-TiOPc with an average particle size of about 89nm.

example 2

[0026] (1) Prepare 1 g of TiOPc particles by vacuum freeze-drying and sol-gel method with the synthesized TiOPc;

[0027] (2) Put 1g of TiOPc particles into a tube furnace with an argon atmosphere, raise it to 350°C at 15°C / min, and keep it warm for 1.5h;

[0028] (3) Quenching with liquid nitrogen to drop below 0°C instantaneously to obtain β-TiOPc with an average particle size of about 122nm.

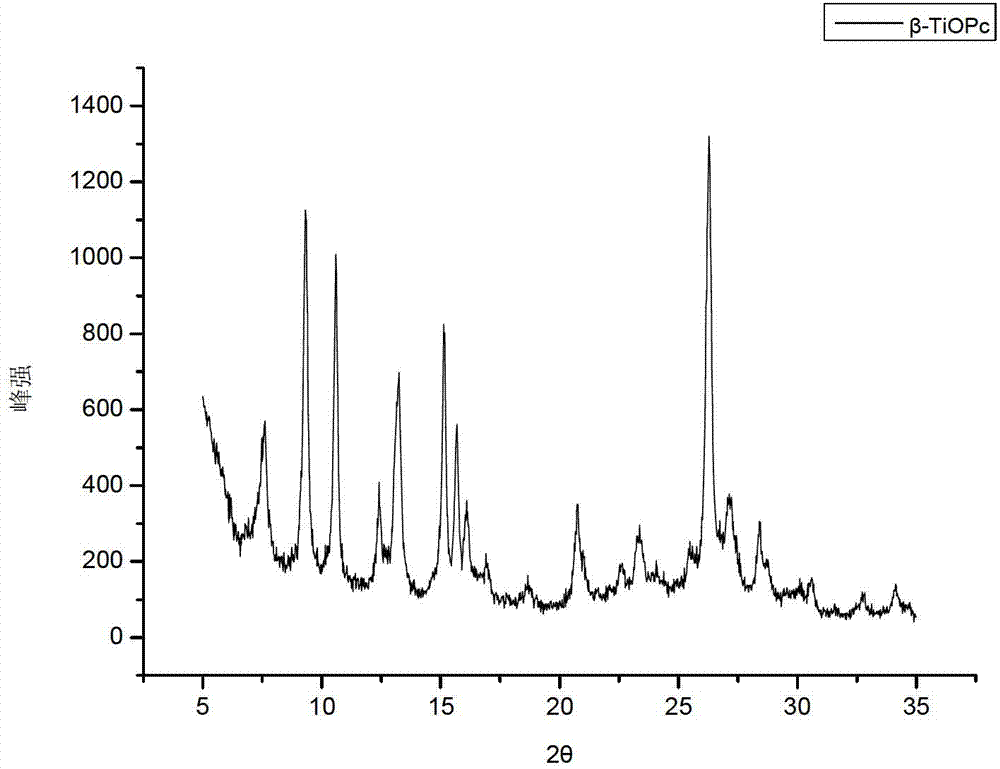

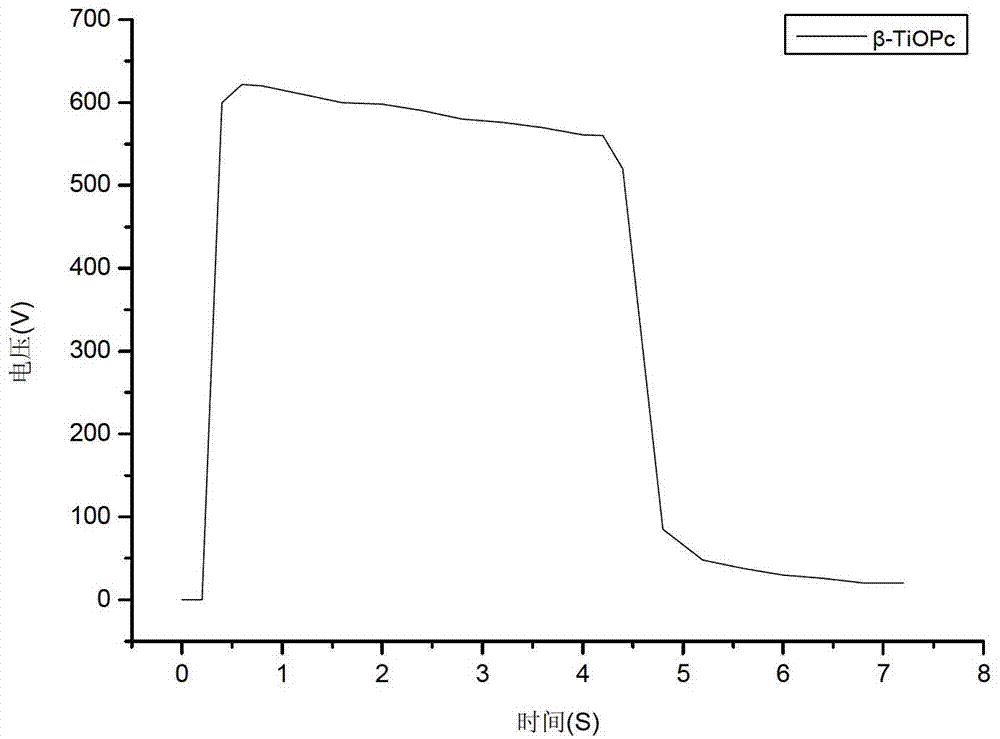

[0029] like figure 1 The X-ray diffraction pattern of the nano-β-TiOPc prepared by shown example 2; figure 2 For adopting the photoelectric performance curve of the nanometer β-TiOPc that example 2 prepares

example 3

[0031] (1) Prepare 1 g of TiOPc particles by vacuum freeze-drying and sol-gel method with the synthesized TiOPc;

[0032] (2) Put 1g of TiOPc particles into a tube furnace with a hydrogen atmosphere, raise it to 375°C at 5°C / min, and keep it warm for 2.5h;

[0033] (3) Naturally cooling the temperature down to room temperature to obtain β-TiOPc with an average particle size of about 135 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com