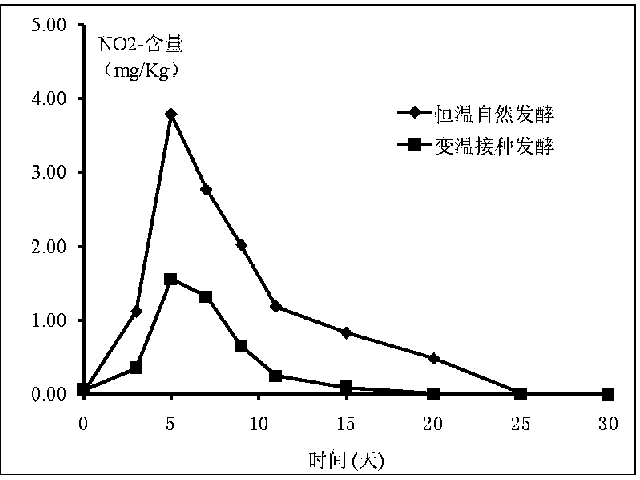

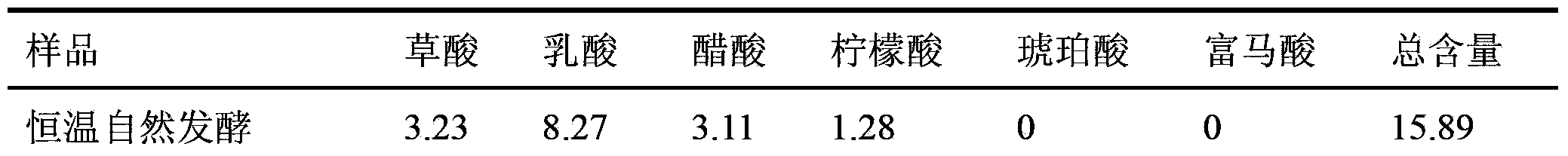

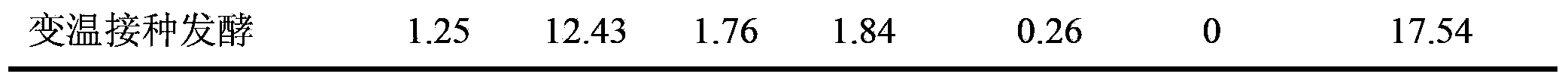

Method for producing Northeast sauerkraut using dynamic variable temperature fermentation technology

A technology of variable temperature fermentation and technology, applied in application, food preparation, food science and other directions, can solve problems such as adverse reactions and improper preparation methods, and achieve the effects of quality control, shortened production cycle, and short production cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Example 1 The method for producing Northeast sauerkraut using dynamic variable temperature fermentation technology

[0013] The specific method is as follows:

[0014] 1) Remove the bad leaves of the cabbage, wash and drain, cut the cabbage over 1kg longitudinally into small pieces of no more than 1kg, with the head and the tail facing each other, put it into the fermentation container, discharge it well, and compact it. Pour into the fermentation broth, submerge the cabbage, the fermentation broth is a sterile sodium chloride aqueous solution with a mass concentration of 3%, seal the fermentation vessel, and carry out 1 internal circulation of the fermentation broth, the speed of the fermentation broth internal circulation is 6L / hour, so that the fermentation liquid mixed evenly;

[0015] 2) Variable temperature fermentation: The fermentation period is 14 days, and the fermentation liquid is circulated every 2 days during the fermentation process, and the speed of the...

Embodiment 2

[0016] Embodiment 2 Utilize the method for producing Northeast sauerkraut by dynamic variable temperature fermentation technology

[0017] The specific method is as follows:

[0018] 1) Strain cultivation: Add Lactobacillus acidophilus to an appropriate amount of nutrient solution and cultivate at 37°C for about 48 hours until the strain concentration is not less than 10 8 CFU / ml;

[0019] 2) Remove the bad leaves of the cabbage, wash and drain, cut the cabbage over 1kg longitudinally into small pieces not exceeding 1kg, with the head and the tail facing each other, put it into the fermentation container, discharge it well, and compact it. Pour into the fermentation liquid, submerge the cabbage, the fermentation liquid is a sterile sodium chloride aqueous solution with a mass concentration of 5%, add Lactobacillus acidophilus with a volume of 0.5% of the fermentation liquid, seal the fermentation container, and carry out 1 internal circulation of the fermentation liquid, The...

Embodiment 3

[0021] Example 3 The method for producing Northeast sauerkraut using dynamic variable temperature fermentation technology

[0022] The specific method is as follows:

[0023] 1) Strain cultivation: Culture Bifidobacterium and Lactobacillus acidophilus at a ratio of 1:3 in the nutrient solution at 37°C for about 48 hours until the concentration of the mixed strain is no less than 10 8 CFU / ml, spare;

[0024] 2) Remove the bad leaves of the cabbage, wash and drain, cut the cabbage over 1kg longitudinally into small pieces not exceeding 1kg, with the head and the tail facing each other, put it into the fermentation container, discharge it well, and compact it. Pour into the fermentation liquid, submerge the cabbage, the fermentation liquid is a sterile sodium chloride aqueous solution with a mass concentration of 1.5%, add mixed bacteria with a volume of 1% of the fermentation liquid, seal the fermentation container, and carry out 1 internal circulation of the fermentation liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com