Use of PDLLLA (Poly Dl Lactic Acid)-PEG (Polyethylene Glycol)-PDLLA triblock copolymer in preparing medical anti-adhesion material

A tri-block and copolymer technology, applied in medical science, surgery, etc., can solve the problems of sol-gel phase transition behavior is not obvious, the solubility of hydrogel is not good enough, and the application prospect is limited, and the gel strength can be achieved. control, comprehensive performance, and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Synthesis and verification of embodiment 1 copolymer

[0040] 1. Synthesis of PDLLA-PEG-PDLLA Copolymer

[0041] The brief synthetic route of PDLLA-PEG-PDLLA copolymer of the present invention is as follows:

[0042]

[0043] Among them, the molecular weight of the PEG segment is 1000 Daltons and 1500 Daltons respectively. By controlling the molar ratio of PEG and DL-LA, a series of PDLLA-PEG-PDLLA copolymers are synthesized. The obtained copolymer materials are listed in the table 1 in.

[0044] According to the synthesis route, a certain amount of polyethylene glycol (PEG) and lactide (PDLLA) were added to a two-necked flask equipped with a stirrer, and stannous octoate was used as a catalyst. The product is obtained after reacting for 8-18 hours, cooled to room temperature, dissolved in ethanol and precipitated in n-pentane, washed three times with n-pentane, and then dried in a vacuum oven.

[0045] According to the method described above, L 800 -E 1000 -L 80...

Embodiment 2

[0053] The preparation method of embodiment 2 polymer aqueous solution

[0054] Since the principle of each PDLLA-PEG-PDLLA tri-block copolymer to make a hydrogel is the same and the conditions are very similar, the following copolymer is taken as an example. The copolymer is dissolved in physiological saline to obtain a copolymer aqueous solution with a concentration of 10-50wt%, preferably 15-40wt%, and then the temperature reaches the phase transition temperature to form a gel in the solution to obtain a medical anti-adhesion material.

[0055] L 1300 -E 1500 -L 1300 , L 1500 -E 1500 -L 1500 , L 1700 -E 1500 -L 1700 Copolymer: Put the weighed copolymer in a certain volume of physiological saline, and stir it at room temperature for 4-5 hours to form a transparent and clear solution, which is ready for use.

[0056] L 800 -E 1000 -L 800 , L 1000 -E 1000 -L 1000 , L 1200 -E 1000 -L 1200 Copolymer: Place the weighed copolymer in a certain volume of physiologi...

Embodiment 3

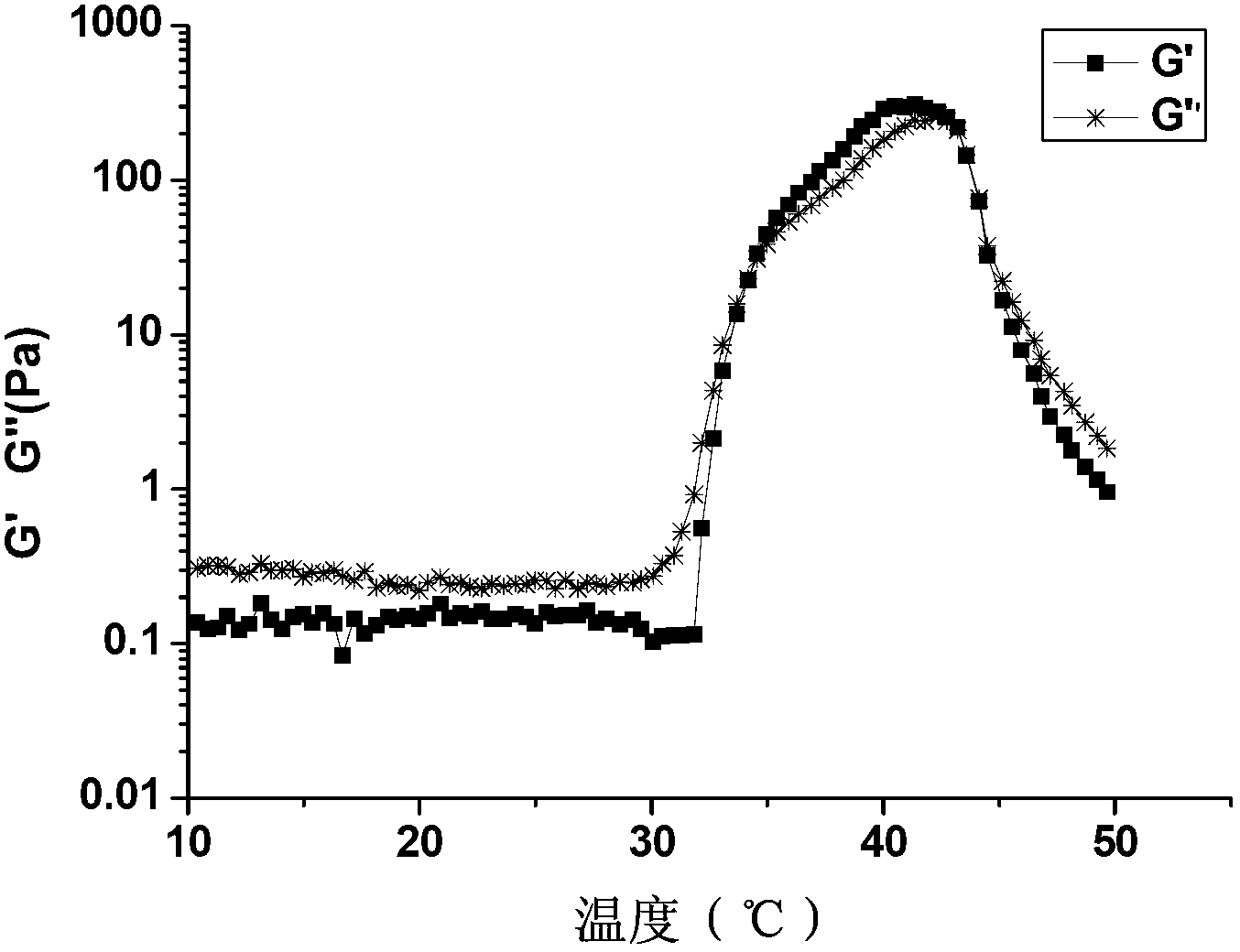

[0061] The temperature sensitivity characterization of embodiment 3 copolymer aqueous solution

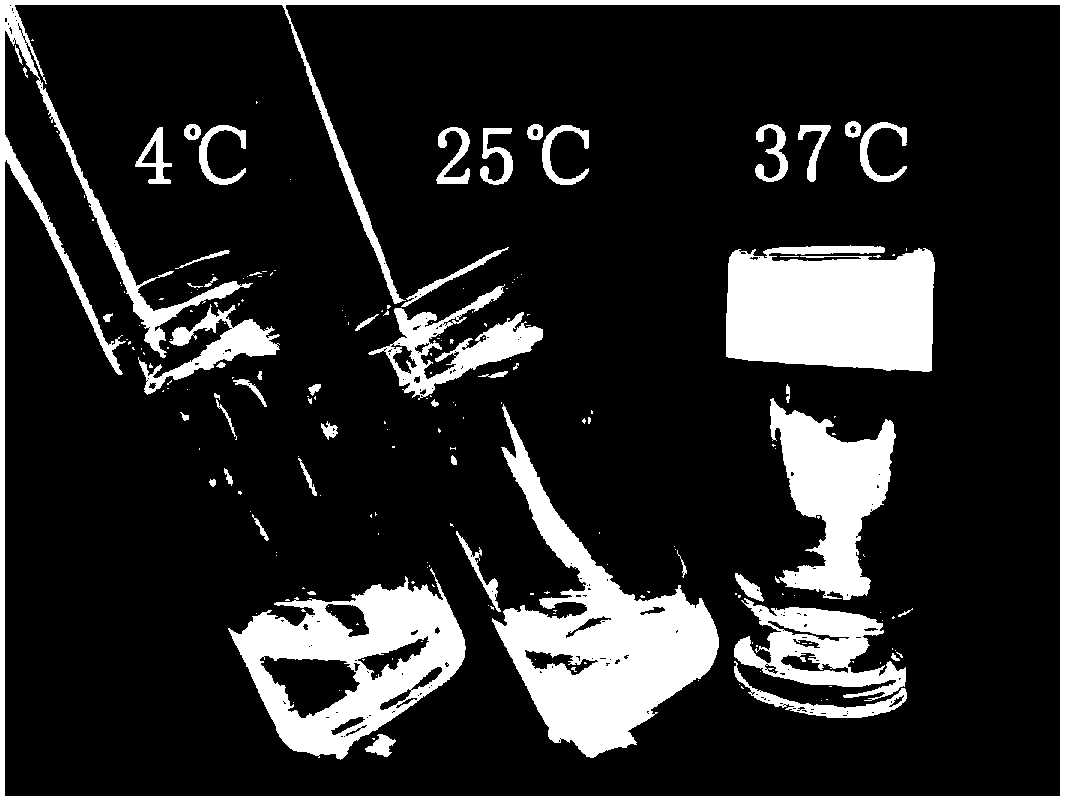

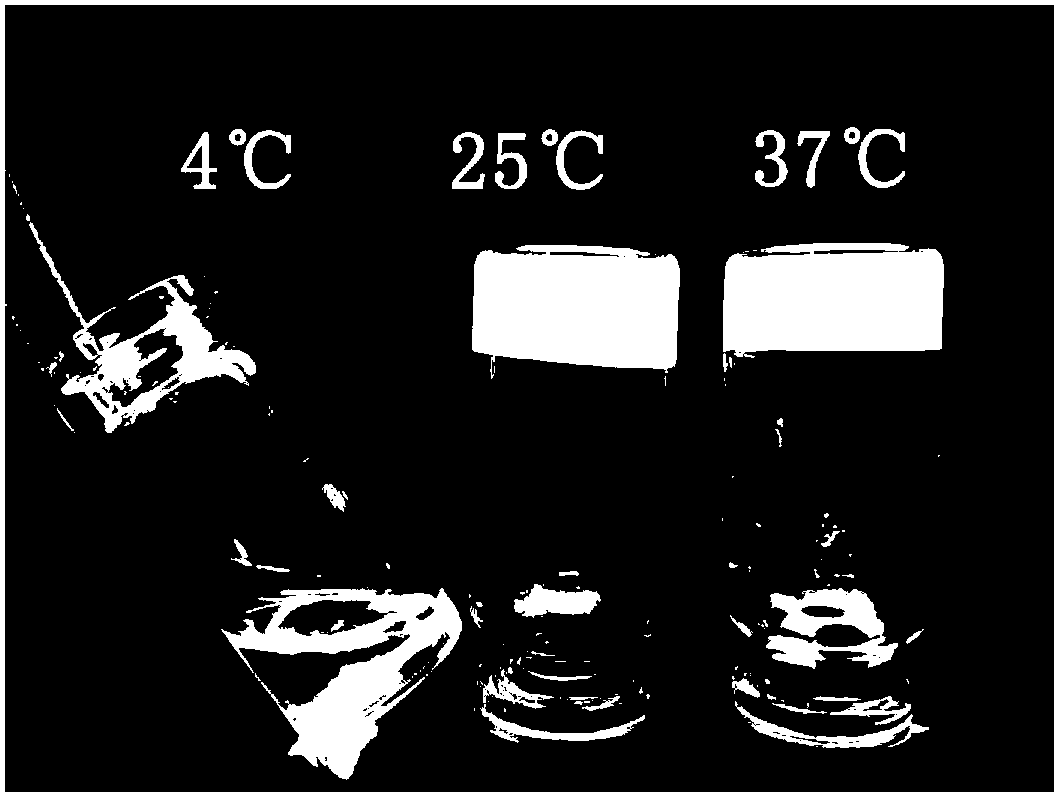

[0062] (1) The apparent state of the polymer aqueous solution at different temperatures is shown in figure 1 and figure 2 , figure 1 for L 1500 -E 1500 -L 1500 (35%), it can be seen that the polymer aqueous solution is a colorless transparent gel state at 37 ° C, and is a solution state at 25 ° C; figure 2 for L 1000 -E 1000 -L 1000 (35%), it can be seen that the polymer aqueous solution is in the state of white gel at 37°C and in the state of solution at 4°C.

[0063] The difference between the two materials is mainly shown in the method of preservation and use. L1000-E1000-1000 is in gel state at room temperature; while 1500-E1500-L1500 is still in sol state at room temperature. It will be more convenient to use L1500-E1500-L1500 in industrial production.

[0064] (2) Phase transition temperature of different concentrations of copolymer

[0065] In order to understa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com