C3N4 nanosheet with molecular-scale thickness as well as preparation method and application thereof

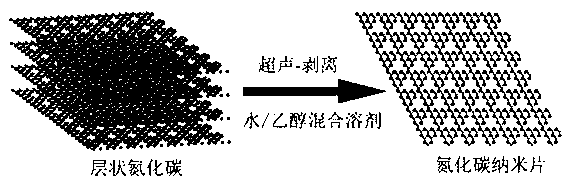

A technology of C3N4 and nanosheets, which is applied in chemical instruments and methods, textile industry wastewater treatment, organic compound/hydride/coordination complex catalysts, etc., can solve the problem of toxic organic solvents, low concentration of suspensions, and nanosheets Low yield and other problems, to achieve the effect of avoiding the use of toxic organic solvents, high concentration, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] First is bulk C 3 N 4 Precursor preparation, weigh 15 g of melamine in a crucible, place it in a muffle furnace for calcination at 550°C for 4 h, grind it for later use; put 0.5 g of bulk C in a beaker 3 N 4 Add 90 mL of deionized water and 105 mL of ethanol to the precursor, then place the beaker in an ultrasonic machine for 4 h, then place the beaker in a stirrer and stir for 14 h, and then sonicate for 4 h to obtain a suspension. Centrifuge at a speed of 3,000 rpm to remove the precipitate, and finally centrifuge at a high speed of 10,000 rpm to obtain molecular-level thickness C 3 N 4 Nanosheet photocatalysts.

Embodiment 2

[0023] First is bulk C 3 N 4 Precursor preparation, weigh 10 g of melamine in a crucible, place it in a muffle furnace for calcination at 550°C for 4 h, grind it for later use; put 0.3 g of bulk C in a beaker 3 N 4 Add 60 mL of deionized water and 70 mL of ethanol to the precursor, then place the beaker in an ultrasonic machine for 4 h, then place the beaker in a stirrer and stir for 5 h, and then sonicate for 4 h to obtain a suspension. Centrifuge at a speed of 10,000 rpm to remove the precipitate, and finally centrifuge at a high speed of 10,000 rpm to obtain molecular-level thick C 3 N 4 Nanosheet photocatalysts.

Embodiment 3

[0025] First is bulk C 3 N 4 Precursor preparation, weigh 15 g of melamine in a crucible, place it in a muffle furnace for calcination at 550°C for 4 h, grind it for later use; put 1.0 g of bulk C in a beaker 3 N 4 Add 90 mL of deionized water and 105 mL of ethanol to the precursor, then place the beaker in an ultrasonic machine for 5 h, then place the beaker in a stirrer and stir for 14 h, and then sonicate for 3 h to obtain a suspension. Centrifuge at a speed of 3,000 rpm to remove precipitates, and finally centrifuge at a high speed of 10,000 rpm to obtain molecular-level thick C 3 N 4 Nanosheet glue photocatalyst.

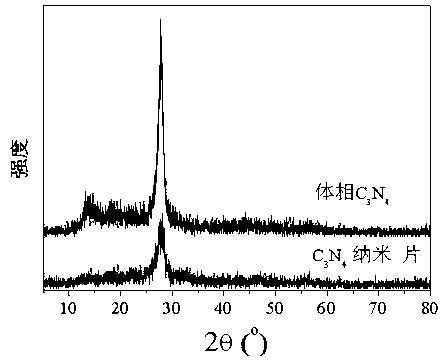

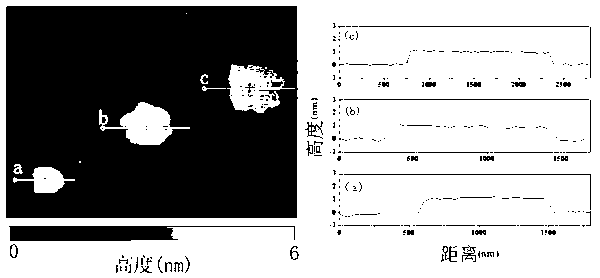

[0026] From figure 2 Molecular-scale thicknesses of C can be found in 3 N 4 The XRD diffraction peaks of the nanosheets were significantly weakened or even disappeared, indicating that the bulk C 3 N 4 Nanosheets with monolayer thickness have been successfully fabricated. From image 3 The prepared molecular-scale thickness of C can be found in 3 N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com