Preparation method of degradable lacrimal passage bracket with shape memory function

A technology of lacrimal duct and memory, applied in the preparation of lacrimal duct stents, the preparation of degradable lacrimal duct stents with shape memory function, and the preparation of degradable lacrimal duct stent materials, which can solve the problems of increasing drainage space and achieve easy Implantation, effect of small diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

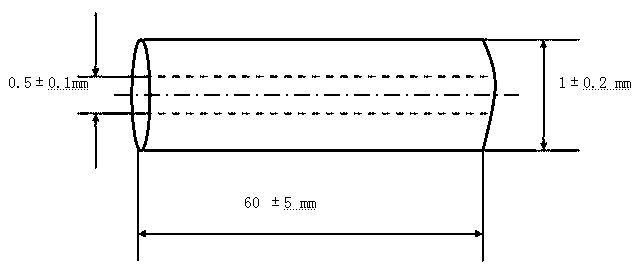

Embodiment 1

[0037] Using L-lactic acid and 1,4-butanediol as raw materials, the molar ratio of L-lactic acid and 1,4-butanediol is 3:4, after dehydration treatment, adding catalyst stannous octoate (0.8 wt%), Polymerization was carried out for 18 hours at 160° C. and a pressure of 60 Pa. After the reaction, tetrahydrofuran was added to dissolve, then methanol was added to precipitate and purify the product, and vacuum-dried to obtain a white powdery copolymer with a glass transition temperature of about 31 °C and a weight-average molecular weight of about 15,000. Add chain extender diphenylmethane diisocyanate (MDI) in the obtained white powdery copolymer, the molar ratio of chain extender and copolymer is 1:1, add 0.01 wt% chain extension catalyst bis(dodecyl sulfide base) dibutyltin, N 2 Melt chain extension under protection, the reaction temperature is 170 ℃, the time is 50 minutes, and the pressure is 60 Pa. After the reaction is completed, tetrahydrofuran is added to dissolve, then ...

Embodiment 2

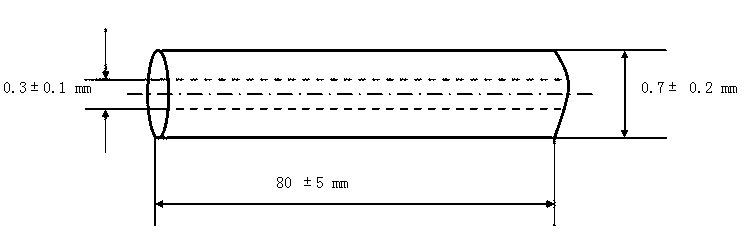

[0039] Using L-lactic acid and 1,4-butanediol as raw materials, the molar ratio of L-lactic acid and 1,4-butanediol is 3:4, after dehydration treatment, adding catalyst stannous octoate (0.6 wt%), Polymerization was carried out at 160° C. and a pressure of 60 Pa for 18 hours. After the reaction, tetrahydrofuran was added to dissolve, then methanol was added to precipitate and purify the product, and vacuum-dried to obtain a white powdery copolymer with a glass transition temperature of about 32 °C and a weight-average molecular weight of about 20,000. The chain extender added in the obtained white powdery copolymer is diphenylmethane diisocyanate (MDI), the molar ratio of the chain extender to the copolymer is 1:1, and 0.01 wt% of the chain extender bis(dodecane) is added Sulfuryl) Dibutyltin, N 2 Melt chain extension under protection, the reaction temperature is 170 ℃, the time is 50 minutes, and the pressure is 60 Pa. After the reaction is completed, tetrahydrofuran is adde...

Embodiment 3

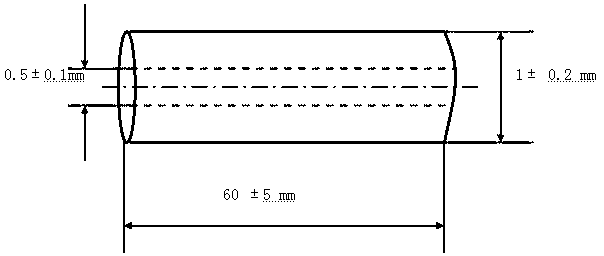

[0041] Using L-lactic acid and 1,4-butanediol as raw materials, the molar ratio of L-lactic acid and 1,4-butanediol is 1:1, after dehydration treatment, adding catalyst stannous octoate (0.5 wt%), Polymerization was carried out for 16 hours at 150 °C and a pressure of 50 Pa. After the reaction, tetrahydrofuran was added to dissolve, then ethanol was added to precipitate and purify the product, and vacuum-dried to obtain a white powdery copolymer with a glass transition temperature of about 31 °C and a weight-average molecular weight of about 25,000. In the obtained white powdery copolymer, adding chain extender is hexamethylene diisocyanate (HDI), the mol ratio of chain extender and copolymer is 1:1, adding 0.01 wt% chain extender bis(dodecane Sulfuryl) Dibutyltin, N 2 Melt chain extension under protection, the reaction temperature is 170 ° C, the time is 50 minutes, and the pressure is 60 Pa. After the reaction is completed, tetrahydrofuran is added to dissolve, then ethanol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com