Preparation method of nanometer fibril enteromorpha cellulose

A technology of nanofibrillation and cellulose, which is applied in fiber raw material processing, textiles and papermaking, etc., to achieve high conversion rate, low density, and increase the effect of tensile strength and elastic modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

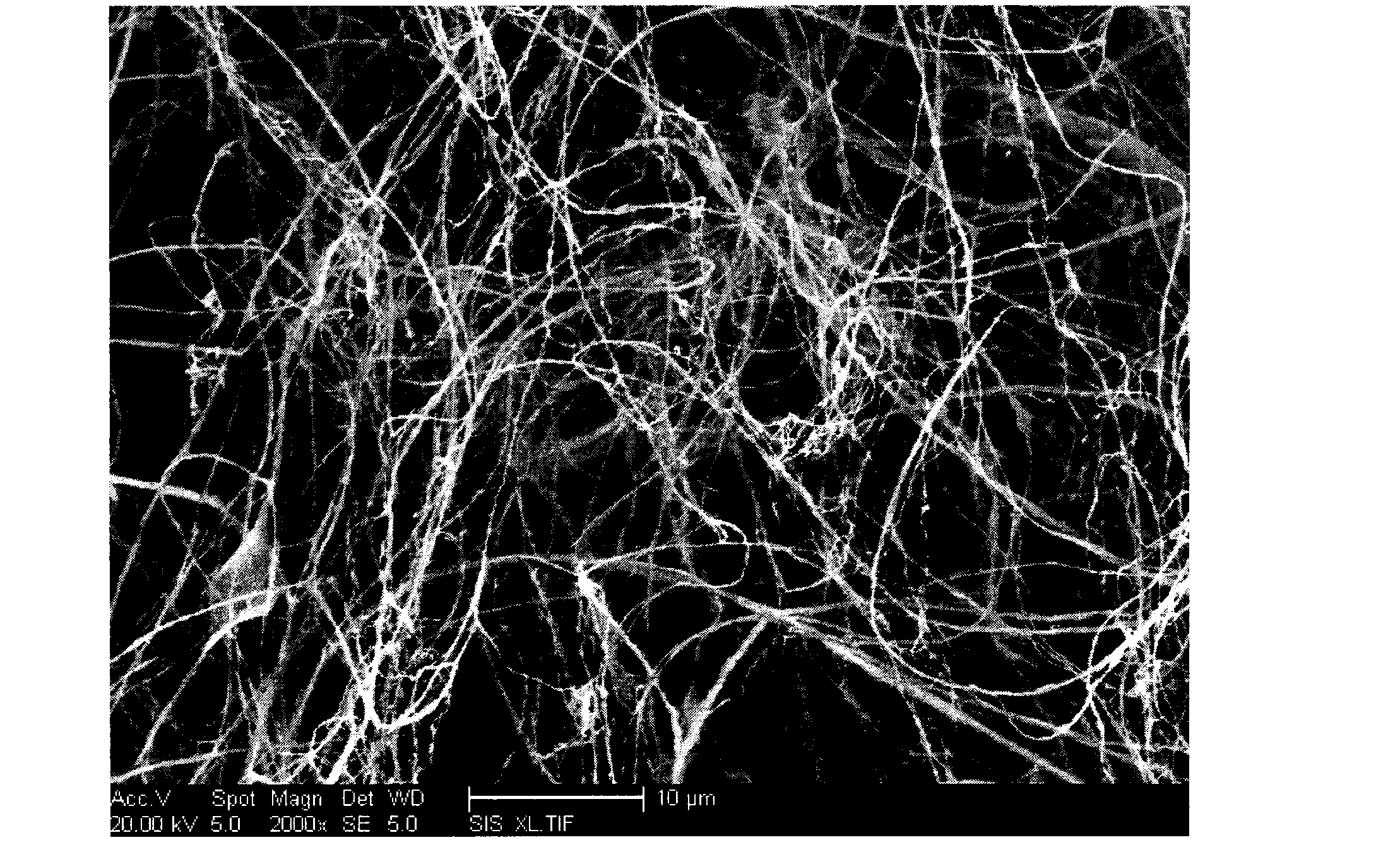

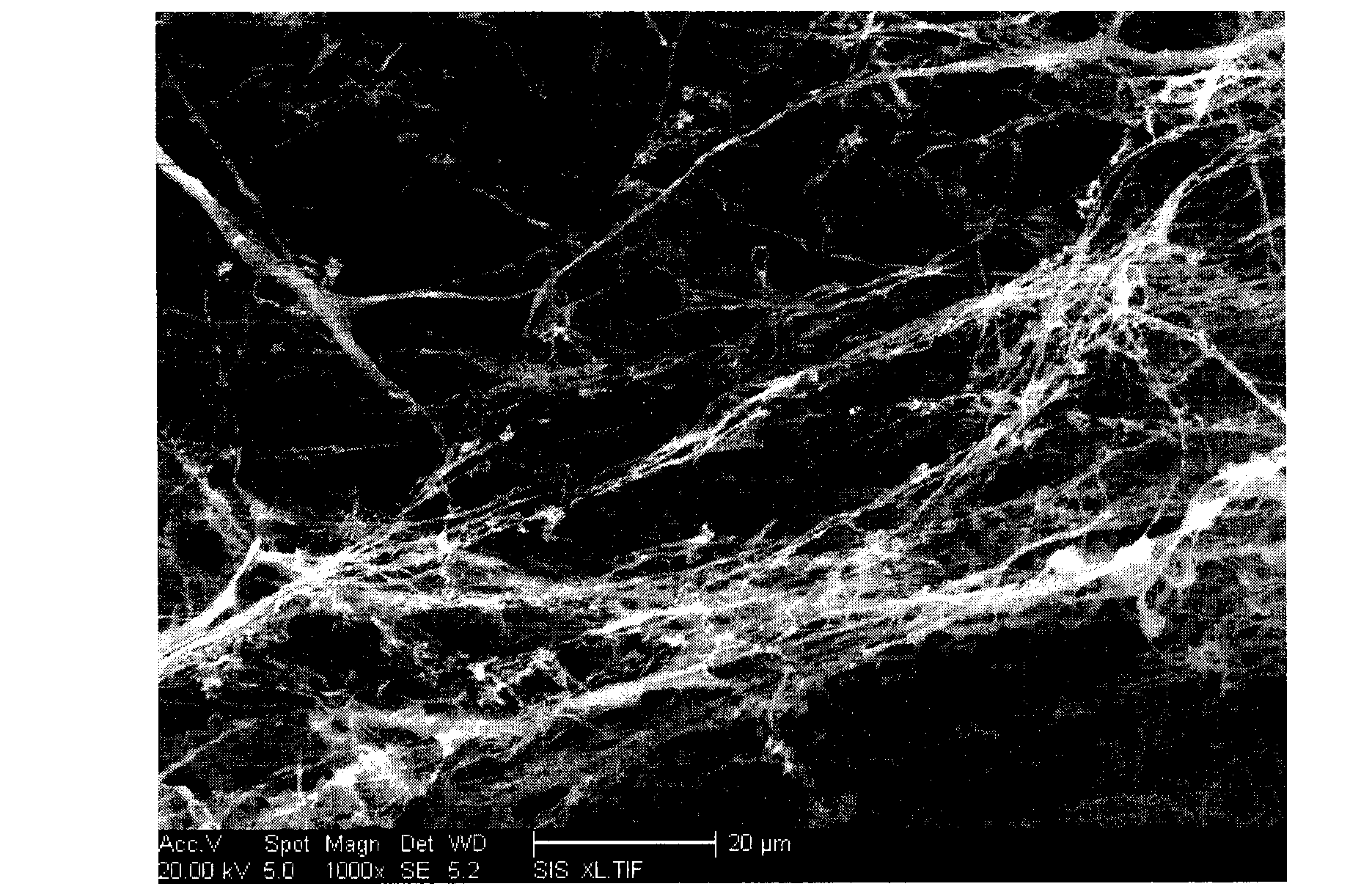

Image

Examples

Embodiment 1

[0029] Embodiment 1: a kind of preparation method of enteromorpha nanofibril cellulose, specifically finish according to the following steps:

[0030] 1. After collecting Enteromorpha, sort and remove miscellaneous algae and other small shellfish, wash, freeze-dry, crush and sieve to obtain 60 mesh Enteromorpha algae dregs powder;

[0031] 2. Mix 5 g of Enteromorpha algal residue powder with 300 mL of distilled water, perform cell crushing pretreatment with an ultrasonic power of 500 W for 20 minutes, and extract polysaccharides in a constant temperature water bath at 65°C for 4 hours;

[0032] 3. Centrifuge the obtained polysaccharide-extracted mixed solution at 3500 rpm for 5 minutes, pour off two-thirds of the liquid, then add distilled water and repeat the above centrifugal cleaning for 5 times to obtain the precipitated waste residue after extracting the crude polysaccharide;

[0033] 4. Add KOH aqueous solution to the precipitated waste residue obtained after extracting ...

Embodiment 2

[0041] Embodiment 2: a kind of preparation method of enteromorpha nanofibril cellulose, specifically finish according to the following steps:

[0042] 1. After collecting Enteromorpha, pick and remove miscellaneous algae and other small shellfish, wash, freeze-dry, crush and sieve to obtain 100 mesh Enteromorpha algae dregs powder;

[0043] 2. Mix 3 g of Enteromorpha algal residue powder with 300 mL of distilled water, perform cell crushing pretreatment with an ultrasonic power of 1000 W for 20 minutes, and extract polysaccharides in a constant temperature water bath at 90°C for 2 hours;

[0044] 3. Centrifuge the obtained mixed solution of polysaccharide extracted at 5500 rpm for 5 minutes, pour off 2 / 3 of the liquid, then add distilled water and repeat the above centrifugal cleaning 5 times to obtain the precipitated waste residue of extracted crude polysaccharide;

[0045] 4. Add NaOH aqueous solution to the precipitated waste residue after extracting the crude polysacchari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com