Method for preparing core-shell organic/cadmium sulfide nanowire heterojunction arrays

An organic nanowire and nanotube array technology, which is applied in the preparation field of core-shell organic cadmium sulfide semiconductor nanowire heterojunction and cadmium sulfide nanotube array, can solve the problem of organic nanowire crystal quality damage, poor controllability, and difficulty in problems of precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

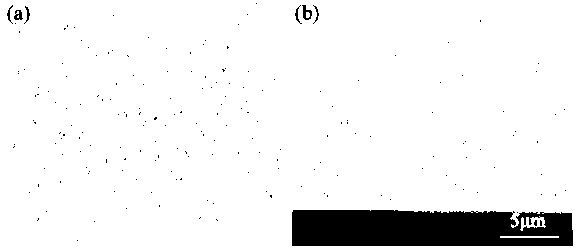

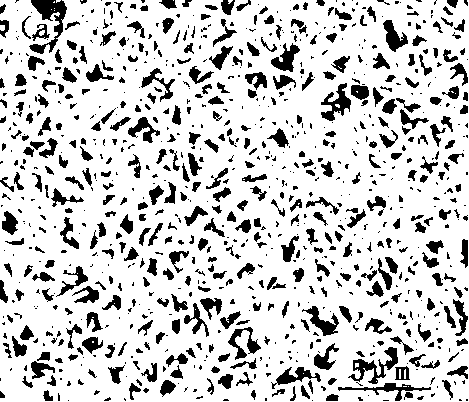

[0042] Example 1: Preparation of CdS-CuPc heterojunction nanowires

[0043] A 6nm gold thin film was deposited on a silicon substrate by electron beam evaporation, and copper phthalocyanine nanowire arrays were grown by physical vapor deposition. Concrete growth parameter is as follows: according to the flowing direction of airflow, the porcelain boat that copper phthalocyanine powder is housed is put into the high-temperature zone of vacuum tube furnace; The center of the temperature zone is about 10-20cm; start the mechanical pump to evacuate, so that the vacuum degree in the furnace chamber of the vacuum tube furnace is below 1Pa, and then pass into the inert gas in the quartz tube, and the gas flow rate is 30-60sccm; when the quartz tube When the medium is completely in an inert gas atmosphere, while maintaining the inert gas inflow; control the tube furnace to increase the temperature to 415 °C at a rate of 20 °C / min, and then keep the temperature for 30 min to fully proc...

Embodiment 2

[0048] Example 2: Preparation of CdS-PTCDA heterojunction nanowires

[0049] Perylenetetracarboxylic dianhydride nanowire arrays were grown by physical vapor deposition. The specific growth parameters are as follows: according to the flow direction of the air flow, a porcelain boat containing an appropriate amount of perylenetetracarboxylic dianhydride powder is placed in the high temperature zone of the vacuum tube furnace; and the cleaned silicon substrate is placed in the low temperature zone of the vacuum tube furnace. Zone, about 10-20cm away from the center of the temperature zone; start the mechanical pump to evacuate, so that the vacuum degree in the furnace chamber of the vacuum tube furnace is below 1Pa, and then pass inert gas into the quartz tube, and the gas flow rate is 30-60sccm; When the quartz tube is completely in an inert gas atmosphere, while keeping the inert gas flowing in, control the tube furnace to raise the temperature to 415°C at a rate of 20°C / min, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com