Lithium sulfur battery cathode material and preparation method thereof

A positive electrode material, lithium-sulfur battery technology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problem that lithium polysulfide is easy to come out and dissolve in organic electrolyte, it is difficult to complete reversible electrochemical reaction, and affect battery cycle performance, etc. problem, to achieve the effect of improving capacity and cycle performance, promoting formation and stability, and improving cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] In a more preferred specific application scheme of the present invention, the preparation method may include:

[0057] (1) Mix sulfur powder and graphene oxide evenly, and react with hydrothermal reaction for 3-10 hours to obtain sulfur / graphene oxide composite, and the product is washed and collected;

[0058] (2) Ultrasonic disperse the product obtained in step (1) in water, add functional polymers or in-situ polymerization of polymer monomers to wrap it, collect the precipitate by centrifugation, and obtain polymer-wrapped sulfur / oxidation after drying Graphene composite;

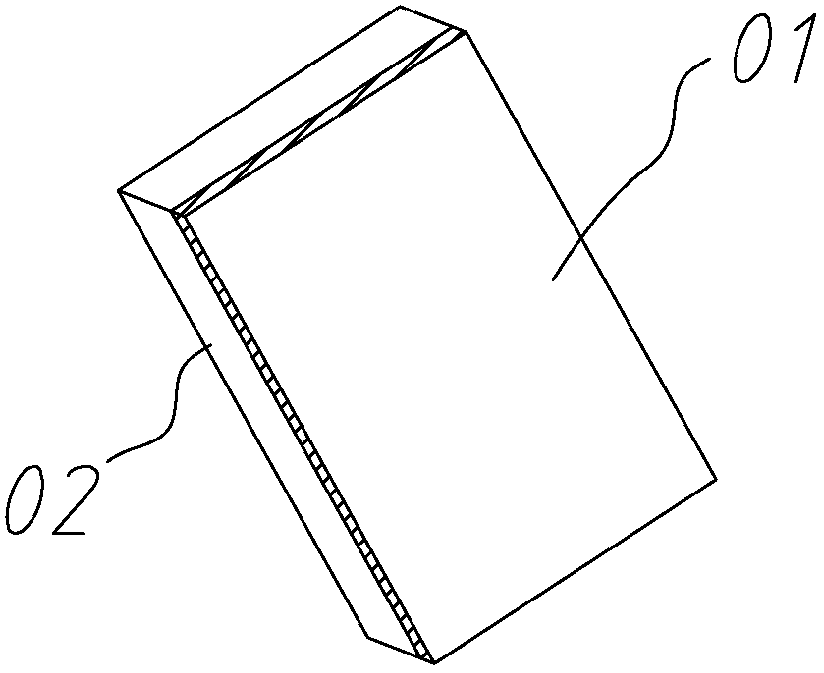

[0059] (3) Mix the polymer-wrapped sulfur / graphene oxide compound obtained in step (2) with carbon black and binder in a certain proportion, homogenize, coat, and react in vacuum at high temperature to obtain lithium-sulfur battery cathode material.

Embodiment 1

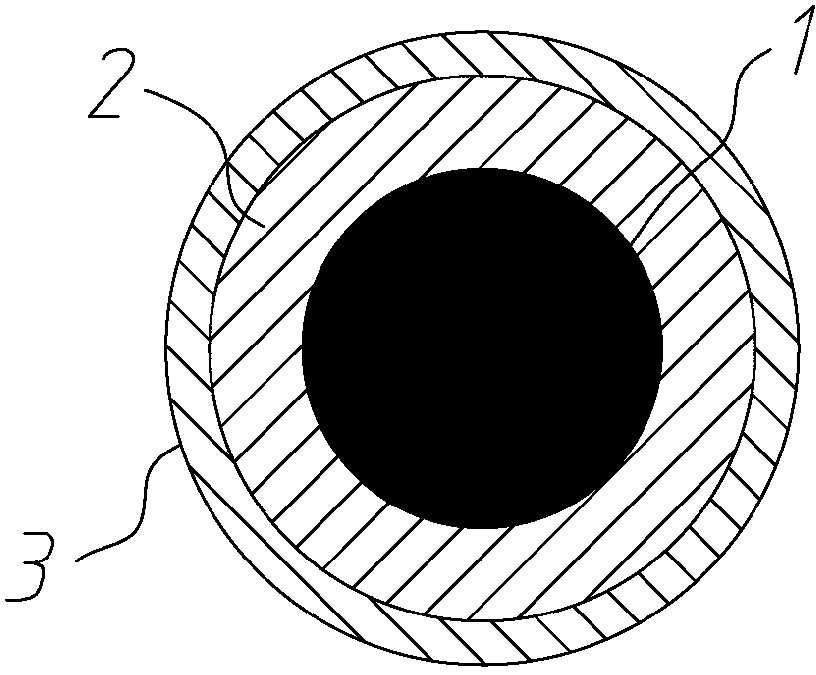

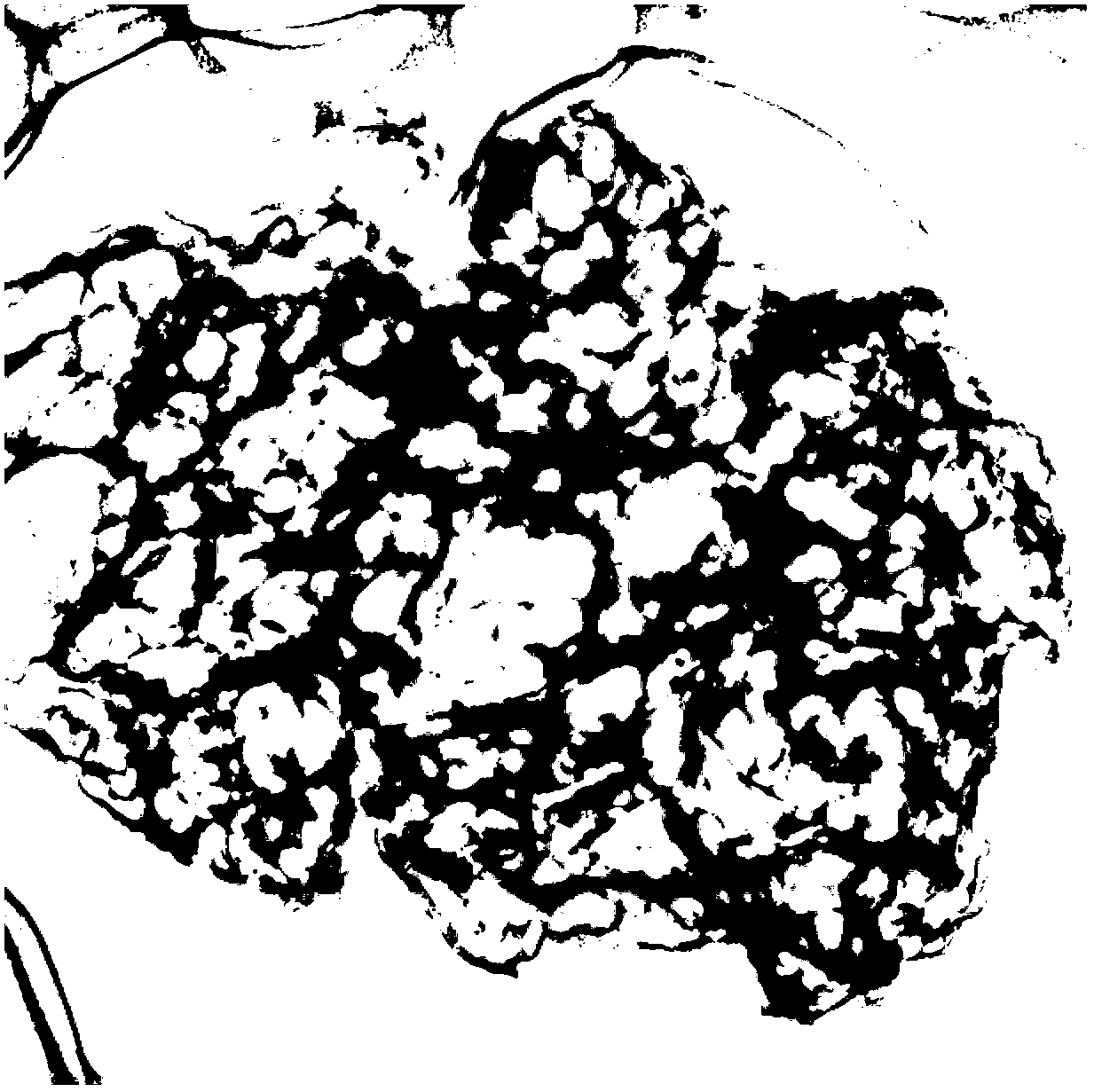

[0061] Example 1 Weigh 10g of sulfur powder and 10g of graphene oxide, dissolve them in 10L of water and stir evenly, place them in water at 150°C for 4-10 hours, then wash the obtained airgel with water, disperse it ultrasonically, and then add 30g of dopamine and ammonia solution in sequence (1 mM), stirred for 2-24h, centrifuged at 5000rpm to separate the precipitate, at 60 o Dry in an oven at C to obtain the active material (for its morphology, see figure 2 ). After that, take 10g of the obtained active material, 1g of carbon black, and 1g of polyacrylic acid, add appropriate amount of water and mix them, stir to make a slurry, apply it on the aluminum foil current collector, and after drying, carry out high-temperature vacuum 200 o C treatment, and then applied as an electrode material for lithium-sulfur batteries, its electrical properties refer to image 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com