Micron-sized molecular sieve supported nano-iron material preparation method

A molecular sieve and nano-iron technology, applied in chemical instruments and methods, silicate, inorganic chemistry, etc., can solve the problems of poor dispersion in water medium, easy to be oxidized or even spontaneous combustion, and poor stability, so as to improve activity and stability And anti-oxidation, the effect of increasing the active site and specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

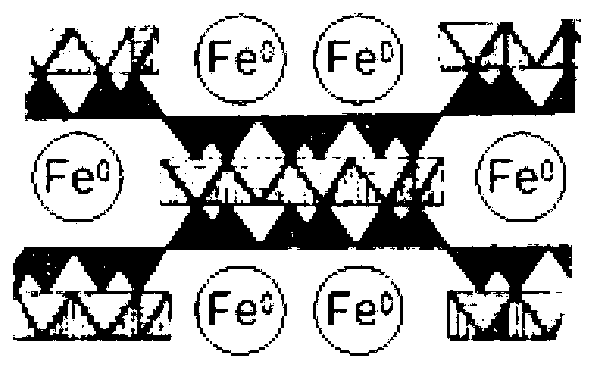

[0026] The preparation method of micron grade molecular sieve loaded nano-iron material of the present invention, the method comprises the following steps:

[0027] (1) Activation pretreatment of molecular sieve carrier

[0028] MCM-41 mesoporous molecular sieve is used as the carrier of micron-sized molecular sieve-loaded nano-iron material, and the carrier is activated and pretreated by heat treatment activation method and acid activation method;

[0029] Heat treatment activation method: the carrier is placed in a muffle furnace, and the carrier is heat-treated to activate the carrier by a stepwise heating and holding method. The activation steps are: heating to 200°C-250°C within 1h-2h, and constant temperature for 1h-2h; Then raise the temperature to 350°C-400°C within 1h-2h, keep the temperature constant for 1h-2h; finally raise the temperature to 550°C-600°C within 1h-2h, keep the temperature constant for 4h-6h;

[0030] Acid activation method: place the carrier activa...

Embodiment 1

[0041] Example 1 Preparation of nano-iron material with a nano-sized molecular sieve-loaded nano-iron material with a mass loading of 25%

[0042] 100ml0.2mol / L FeSO 4 ·7H 2 O can be reduced to produce 1.1g nano-iron

[0043] The mass of the added MCM-41 carrier was 3.0 g.

[0044] The mass loading of nano-iron (%)=1.1g / (1.1g+3.0)×100%=25%.

[0045] Using liquid phase reduction method: for FeSO 4 The ethanol-water solution system, using drop-strengthening reducing agent NaBH 4 to Fe 2+ Reduction is carried out to obtain nano-iron particles.

[0046] At a temperature of 15°C-35°C, mix 3.0g of activated MCM-41 mesoporous molecular sieve with 100ml of 0.2mol / L FeSO 4 ·7H 2 O aqueous solution is placed in a three-necked flask, sealed, and recorded as component A; component A is placed on a magnetic stirrer, nitrogen protection is passed into the three-necked flask, and component A is ultrasonically dispersed for 10 minutes, and magnetic stirring is turned on to make the co...

Embodiment 2

[0049] Example 2 Preparation of nanometer-sized molecular sieve-loaded nano-iron material with a mass loading of nano-iron of 35%

[0050] 100ml0.2mol / L FeSO 4 ·7H 2 O can be reduced to produce 1.1g nano-iron

[0051] The mass of the added MCM-41 carrier was 2.0 g.

[0052] The mass loading of nano-iron (%)=1.1g / (1.1g+2.0)×100%=35%.

[0053] Using liquid phase reduction method: for FeSO 4 The ethanol-water solution system, using drop-strengthening reducing agent KBH 4 to Fe 2+ Reduction is carried out to obtain nano-iron particles.

[0054] At a temperature of 15°C-35°C, mix 2.0g of activated MCM-41 mesoporous molecular sieve with 100ml of 0.2mol / L FeSO 4 ·7H 2 O aqueous solution is placed in a three-necked flask, sealed, and recorded as component A; component A is placed on a magnetic stirrer, nitrogen protection is passed into the three-necked flask, and component A is ultrasonically dispersed for 10 minutes, and magnetic stirring is turned on to make the component A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com