Treatment method of heavy metal wastewater

A treatment method and technology for heavy metals, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of poor denitrification and dephosphor Realize problems such as full factor compliance of refractory heavy metal wastewater, and achieve the effects of increasing concentration and biochemical reaction rate, increasing project cost, and expanding pool capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

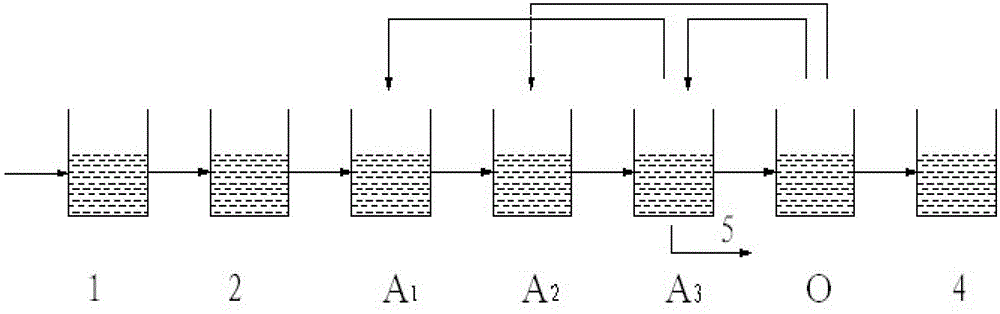

[0034] A kind of processing method of heavy metal waste water, its process flow diagram sees figure 1 , including the following steps:

[0035] (1) The heavy metal wastewater is input into the classification collection and treatment device 2 through the wastewater collection device 1; in the specific treatment process, according to the production situation of the workshop, the heavy metal wastewater to be treated is first classified according to the production process, and the heavy metal wastewater is divided into pre-treatment water, Comprehensive water, mixed drainage, nickel-containing water, chromium-containing water, phosphorus-containing water, copper-containing water and cyanide-containing water; then adjust the pH to 8-9, flocculation sedimentation, redox and / or microelectrolysis and other conventional pretreatment .

[0036] (2) Input the supernatant of the wastewater treated in step (1) into the hydrolytic acidification reaction pool A in sequence 1 , Anoxic denit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com