Cold construction color cementing material for resin concrete

A technology of cementing materials and colored resins, applied in the direction of epoxy resin glue, adhesives, adhesive types, etc., can solve the problems of high energy consumption, small driving vibration, poor driving comfort, etc., and achieve excellent low temperature performance and fatigue resistance , facilitate large-scale promotion, excellent rutting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: A kind of cementitious material of cold construction colored resin concrete, is prepared by following components:

[0028] Mix 30kg of bisphenol A type epoxy resin with 68.3kg of cycloaliphatic glycidyl ether epoxy resin, add 0.4kg of carboxyl-terminated liquid nitrile rubber (CTBN) prepolymer, 0.8kg of γ-aminopropyl three Ethoxysilane, 0.5kg of 2-hydroxyl-4-n-octyloxybenzophenone were mixed and stirred at 25°C for 60 minutes until uniform to form a modified composite epoxy resin.

[0029] Mix 96kg of 2,4,6-tris(dimethylaminomethyl)phenol, 2.2kg of phenylenedioctyl phosphite and 1.8kg of lauryl phenylacetate at 25°C for 40min until uniform and into a modified curing agent.

[0030] 78kg of the modified composite epoxy resin and 22kg of the modified curing agent were conventionally mixed, and then 1kg of the pigment N-N-dimethylaniline (emerald green) was added and mixed to make a colored resin concrete.

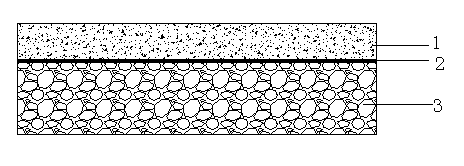

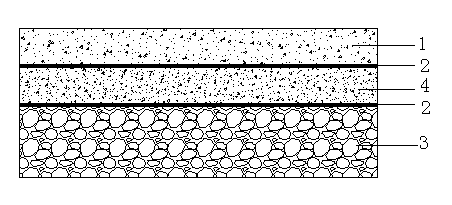

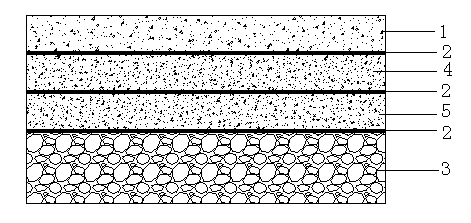

[0031] Construction example: After painting the s...

Embodiment 2

[0032] Embodiment 2: A kind of cementitious material of cold construction colored resin concrete, is prepared by following components:

[0033] Mix 58kg of bisphenol A epoxy resin, 38kg of polyurethane modified epoxy resin (such as 102D polyurethane modified epoxy resin of Jiangyan Hengchuang Insulation Material Co., Ltd.), 0.8kg of polypropylene glycol diglycidyl ether, 2.0kg Vinyltrimethoxysilane and 1.2kg of 2,4,6-tri-tert-butylphenol were mixed and stirred at room temperature for 40 minutes until uniform to form a modified composite epoxy resin.

[0034] Mix and stir 98.7 kg of methyltetrahydrophthalic anhydride, 0.8 kg of dibutyltin dichloride and 0.5 kg of polydimethylsiloxane at room temperature for 30 minutes until uniform to form a modified curing agent.

[0035] Colored resin concrete obtained by conventionally mixing 65kg of the modified composite epoxy resin and 35kg of the modified curing agent, adding 1.5kg of iron oxide red pigment, and stirring at room temperat...

Embodiment 3

[0037] Embodiment 3: A kind of cementitious material of cold construction colored resin concrete, is prepared by following components:

[0038] With 45kg bisphenol A type epoxy resin, 52.1kg alicyclic glycidyl ether epoxy resin, 0.6kg linoleic acid dimer diglycidyl ether, 1.4kg gamma-(2,3-epoxypropoxy Base) Propyltrimethoxysilane, 0.9kg of p-tert-butylphenol were mixed and stirred for 30min at 25°C until uniform to form a modified composite epoxy resin.

[0039] Mix and stir 97.3 methyl hexahydrophthalic anhydride, 1.5kg hexamethylphosphoric triamide) and 1.2kg silicone glycol above 25°C for 50 minutes until uniform to form a modified curing agent.

[0040]Mix 72kg of the composite epoxy resin and 28kg of the modified curing agent, add 2kg of pigment 1,2-bis(o-aminophenoxy)ethane, mix and stir for 30 minutes above 25°C until uniform to form a colored resin concrete .

[0041] Construction example: paint the special adhesive layer 2 on the base layer 3, then lay 2-6cm ordinar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com