Synephrine loaded multiple emulsion and preparation method thereof

A technology of multiple emulsions and synephrine, applied in emulsion delivery, skin care preparations, medical preparations containing active ingredients, etc., can solve problems such as poor fluidity, prolonged production cycle, high freezing point, etc., and achieve weight loss Firm and elastic, without any irritation, to accelerate the effect of local weight loss

Active Publication Date: 2013-09-04

HUNAN XINLI BIOLOGICAL SCI & TECH +1

View PDF3 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

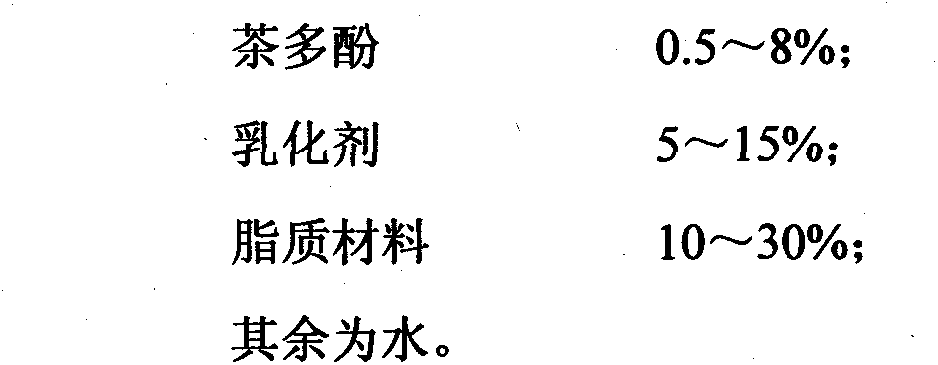

[0009] The main disadvantages of this multi-emulsion are: ① only the active ingredient tea polyphenols is loaded, and the effect of this multi-emulsion is too single. In view of the increasing requirements of modern people for functional cosmetics, it is expected that a cosmetic can achieve both moisturizing and anti-aging It can also have the effect of local slimming and eliminating edema, so the emulsion loaded with only one active component of tea polyphenols cannot meet the needs of the public; ②polyglyceryl stearate, polyglyceryl fatty acid ester, phospholipid and The price of sucrose ester is expensive and its weight percentage is as high as 15%, and the cost of the produced product is higher; 3. the freezing point of polystearin and phosphatide is higher, and the preparation of multiple emulsions is paste at normal temperature, and the fluidity is not good , poor extensibility when applied to the skin, resulting in tea polyphenols not being able to exert their effects well on the skin

The main shortcoming of this multiple emulsion preparation method is: adopting high-pressure homogeneous method to prepare primary emulsion is divided into two steps, and (1) step adopts the high-speed agitation that rotating speed is 8000rpm / min~12000rpm / min to prepare uniform emulsion, high rotating speed The performance requirements of the equipment are high, and the energy consumption is high, thereby increasing the production cost; (2) the emulsion prepared in the (1) step is prepared by a high-pressure homogenizer to obtain the water-in-oil colostrum, The production cycle is extended, and the equipment cost of the high-pressure homogenizer is increased, which further increases the cost

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0033] Components and mass percentages thereof of a multiple emulsion loaded with synephrine are:

[0034]

[0035]

Embodiment 2

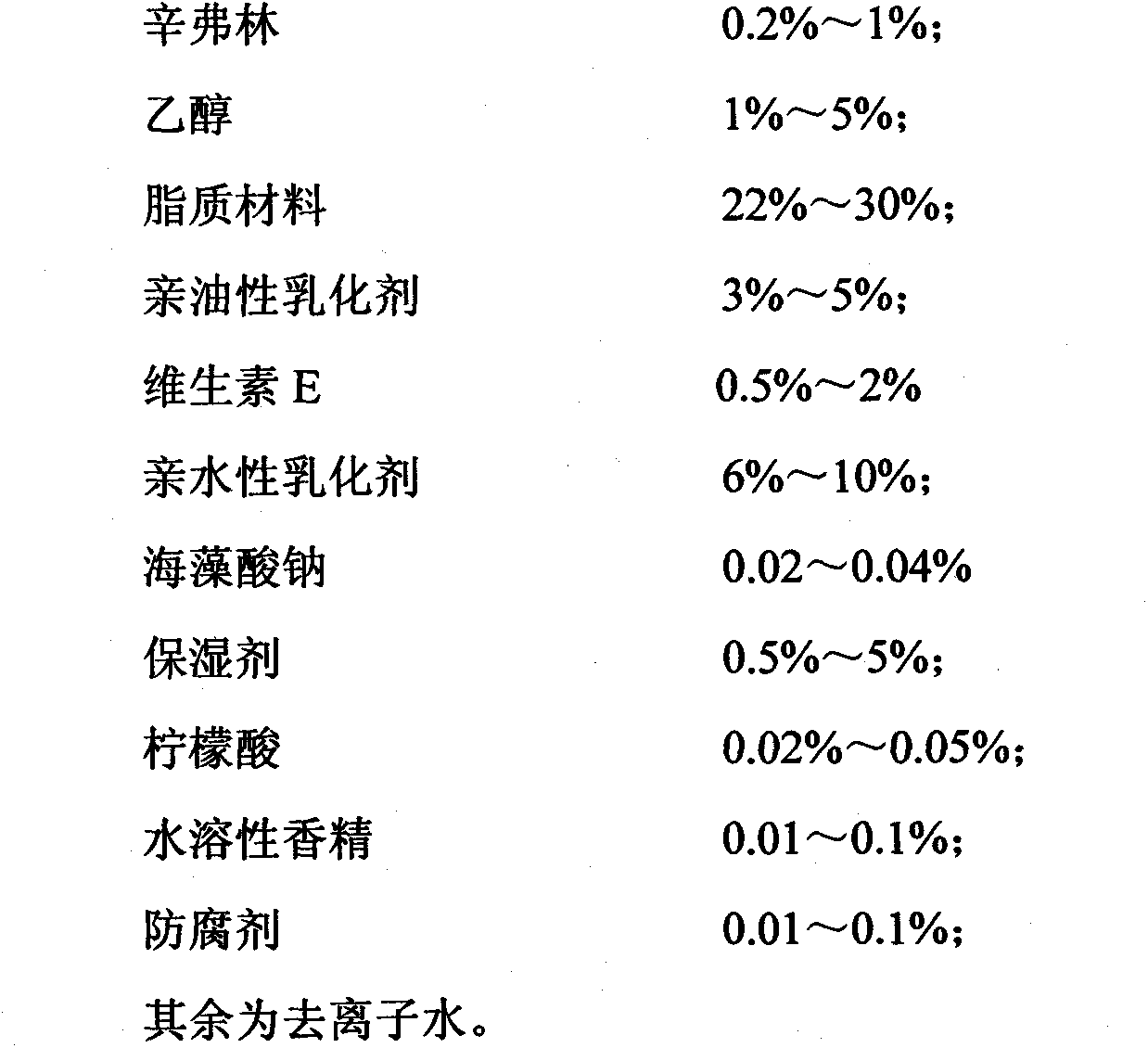

[0037] Components and mass percentages thereof of a multiple emulsion loaded with synephrine are:

[0038]

Embodiment 3

[0040] Components and mass percentages thereof of a multiple emulsion loaded with synephrine are:

[0041]

[0042]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

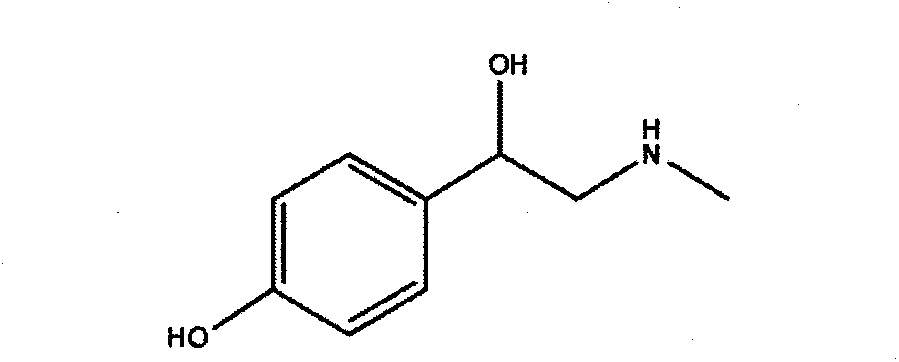

The invention discloses a synephrine loaded multiple emulsion and a preparation method thereof and belongs to the technical field of efficacy cosmetics. The multiple emulsion is composed of synephrine, ethanol, lipid material, lipophilic emulsifier, Vitamin E, hydrophilic emulsifier , sodium alginate, humectant, citric acid, preservative agent, water-soluble essence and deionized water. The method comprises the following steps: taking the components of the multiple emulsion as raw materials; and preparing internal water phase of the synephrine, the liquid oil phase of the synephrine and external water phase of the synephrine respectively. The method has the advantages of simple process, low energy consumption, good safety and the like. The multiple emulsion has the efficacy of oxidation resistance, moisture holding and partial weight losing, has nonirritant and no side effects, and also has characteristics of favorable high-temperature resistance and low temperature resistance, high stability and the like. The method can be widely applied to prepare active ingredient loaded multiple emulsions, and is particularly suitable for preparing the synephrine loaded multiple emulsion. The synephrine loaded multiple emulsion can be widely applied to cosmetics and pharmaceuticals.

Description

technical field [0001] The invention belongs to the technical field of functional cosmetics, and in particular relates to a multiple emulsion loaded with active ingredients and a preparation method thereof. Background technique [0002] Multiple emulsions are a composite system in which oil-in-water (O / W) and water-in-oil (W / O) emulsions coexist. / O / W) and oil-in-water-in-oil (O / W / O). The main advantages of multiple emulsions are: ① It can dissolve different active substances in three different phase areas separated by membranes and prevent their interactions. For example, W / O / W multiple emulsions can make two different water-soluble active substances (such as Proteins, enzymes and vitamins) and an oil-soluble substance (such as spices) exist in the same cosmetic; ② can effectively control the dispersion process of multiple emulsions, so that the active ingredients can be released slowly and persistently; ③ can be prepared into an emulsion system product For pastes with th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): A61K8/41A61K8/67A61K8/92A61K8/84A61K8/06A61K31/355A61K9/113A61Q19/00A61Q19/08A61P3/04A61P17/18A61K31/137

Inventor 周志明王瑶环张龙周小华袁小芳余浩余淼英袁观海

Owner HUNAN XINLI BIOLOGICAL SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com