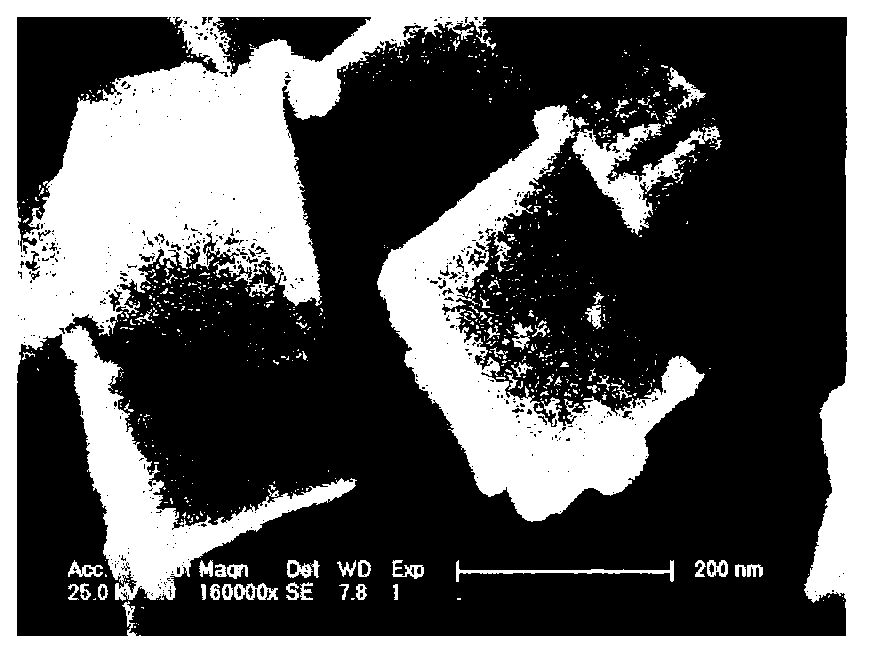

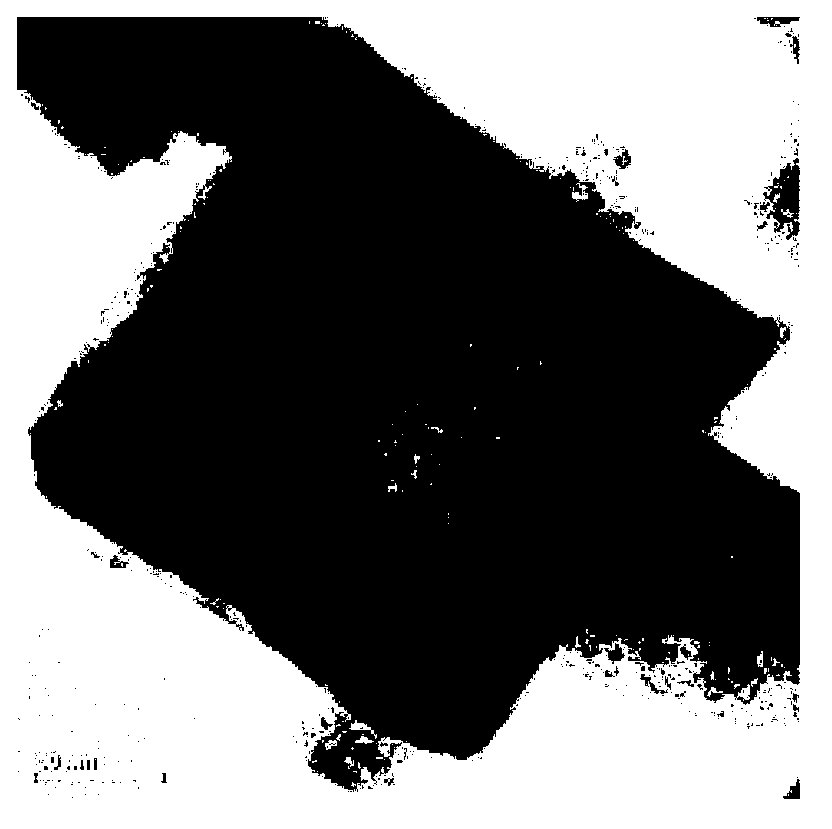

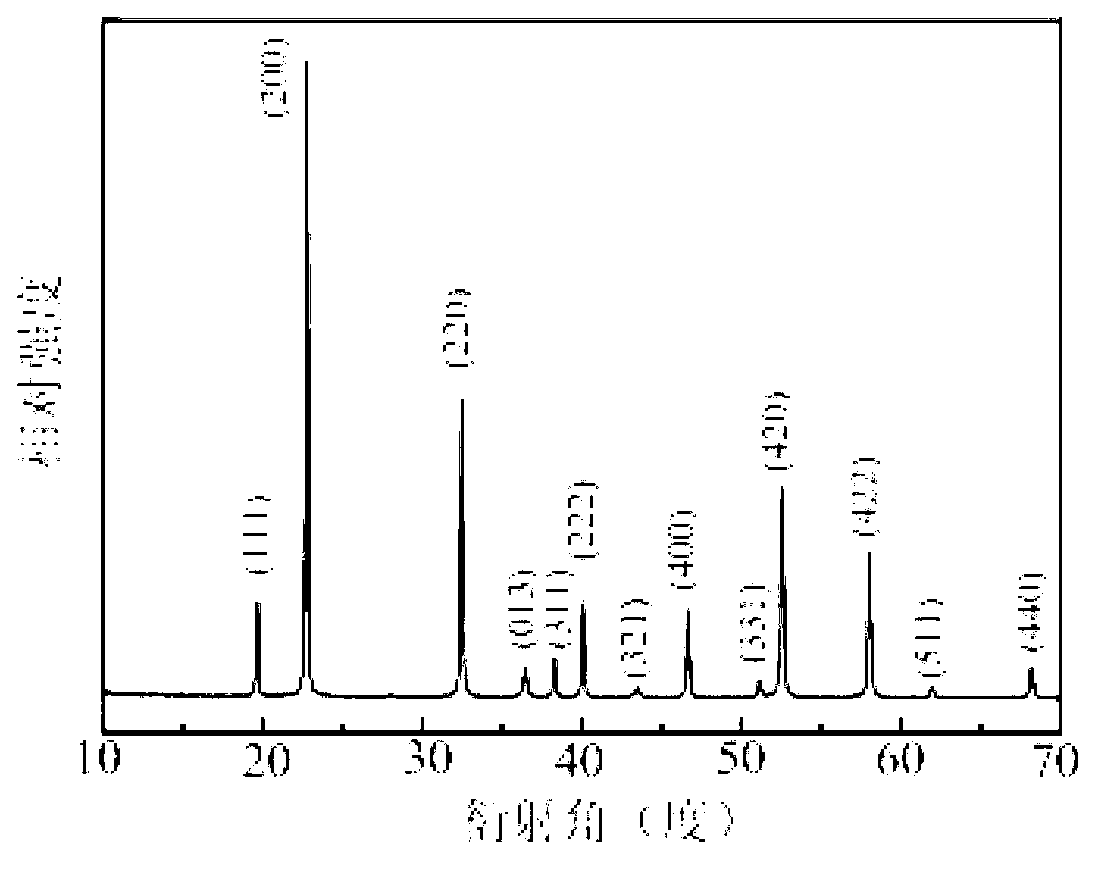

Preparation method of submicron hydroxy zinc stannate cubic material

A technology of micron zinc hydroxystannate and zinc hydroxystannate, applied in chemical instruments and methods, tin compounds, inorganic chemistry, etc., to achieve the effects of reducing pollution, easy regulation, reducing production costs and process complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Mix the raw materials cetyltrimethylammonium bromide, n-hexanol, cyclohexane and deionized water, wherein the concentration of cetyltrimethylammonium bromide is 0.06-0.5 mol / liter, The concentration of cyclohexane is 2-5 mol / liter, and the ratio of the amount of substance of deionized water to the amount of cetyltrimethylammonium bromide is 110-340, the amount of substance of n-hexanol and The ratio of the amount of substances of cetyltrimethylammonium bromide is 10-55;

[0027] (2) Mix the above mixture evenly and make two equal parts, one part is added with zinc sulfate, the other part is added with sodium stannate, stirred at a temperature of 20-100 degrees Celsius for 10-40 minutes, respectively prepared to contain sulfuric acid Two homogeneous microemulsions of zinc and sodium stannate, wherein the concentration of zinc sulfate is 0.1-0.5 mol / liter, and the concentration of sodium stannate is 0.1-0.5 mol / liter;

[0028] (3) Mix the above two microemulsions tog...

Embodiment 2

[0031] (1) Mix the raw materials cetyltrimethylammonium bromide, n-hexanol, cyclohexane and deionized water, wherein the concentration of cetyltrimethylammonium bromide is 0.1-0.6 mol / liter, The concentration of cyclohexane is 1-4 mol / liter, and the ratio of the amount of substance of deionized water to the amount of cetyltrimethylammonium bromide is 80-300, the amount of substance of n-hexanol and The ratio of the amount of substances of cetyltrimethylammonium bromide is 5-60;

[0032] (2) Mix the above mixture evenly and make two equal parts, one part is added with zinc sulfate, the other part is added with sodium stannate, stirred at a temperature of 15-40 degrees Celsius for 10-30 minutes, respectively prepared to contain sulfuric acid Two homogeneous microemulsions of zinc and sodium stannate, wherein the concentration of zinc sulfate is 0.2-0.6 mol / liter, and the concentration of sodium stannate is 0.2-0.6 mol / liter;

[0033] (3) Mix the above two microemulsions togethe...

Embodiment 3

[0036] (1) Mix the raw materials alkylphenol polyoxyethylene ether, n-pentanol, cyclohexane and deionized water, wherein the concentration of alkylphenol polyoxyethylene ether is 0.08-0.45 mol / liter, and the concentration of cyclohexane It is 2.5-5.5 mol / liter, and the ratio of the amount of substance of deionized water to the amount of alkylphenol polyoxyethylene ether is 100-350, the amount of substance of n-amyl alcohol and alkylphenol polyoxyethylene ether The ratio of the amount of substances is 9-60;

[0037] (2) Mix the above mixture evenly and make two equal parts, one part is added with zinc sulfate, the other part is added with sodium stannate, stirred at a temperature of 25-45 degrees Celsius for 10-30 minutes, respectively prepared to contain sulfuric acid Two homogeneous microemulsions of zinc and sodium stannate, wherein the concentration of zinc sulfate is 0.3-1.2 mol / liter, and the concentration of sodium stannate is 0.3-1.2 mol / liter;

[0038] (3) Mix the abo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com