Method for producing organic fertilizer by utilizing hickory hulls

A hickory cattail shell and organic fertilizer technology, which is applied in the preparation of organic fertilizers, organic fertilizers, and the treatment of biological organic parts, etc., can solve the problem that the product quality is difficult to meet the requirements, the temperature is only 45-55 ℃, and the product is not completely decomposed, etc. Problems, to achieve the effect of improving the quality of agricultural products, good quality, and reducing crop pests and diseases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

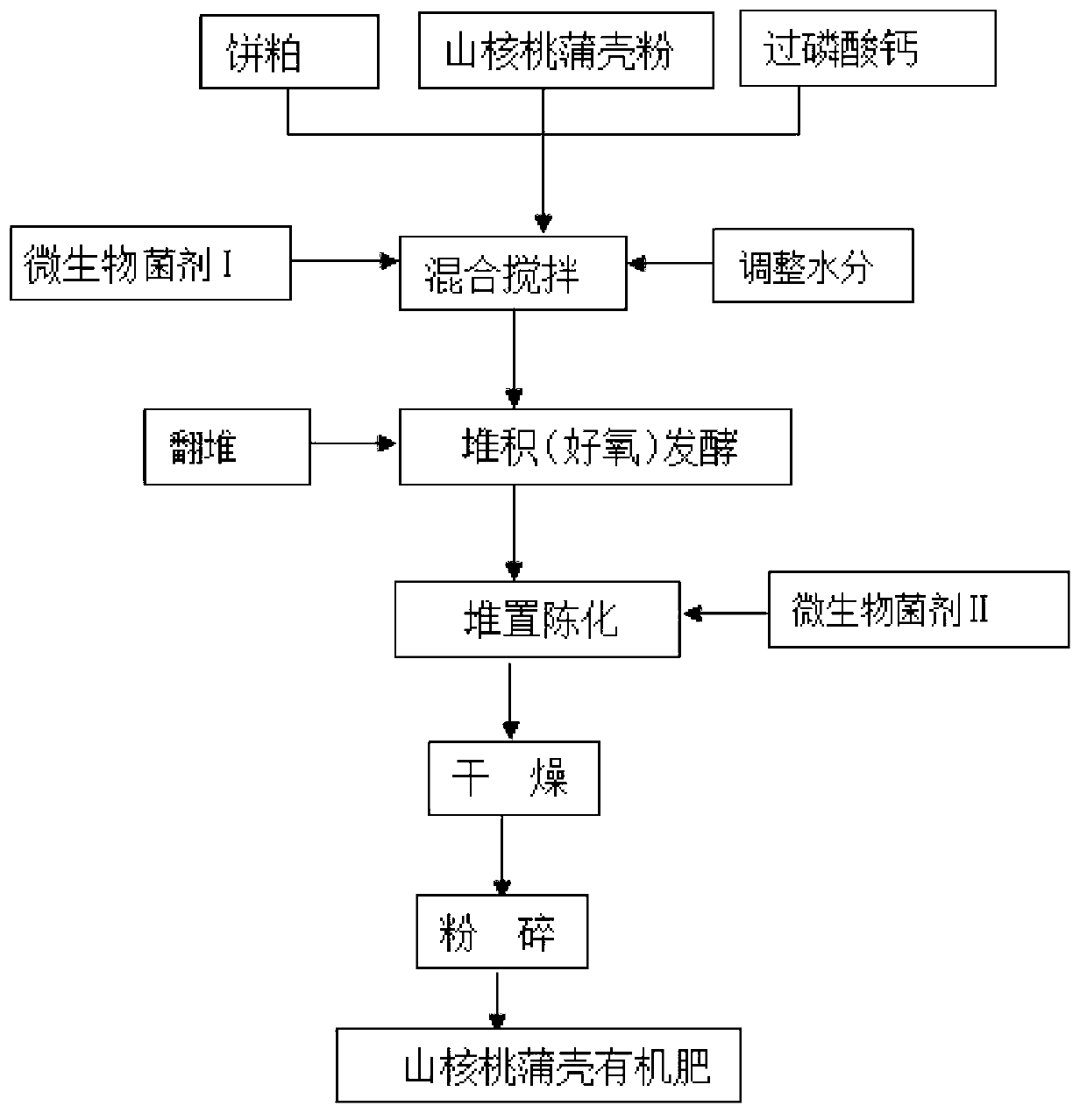

Image

Examples

Embodiment 1

[0031] Step ①, material mixing

[0032] Hickory cattail shells are crushed into cattail shell powder with a particle size of 1.3mm to 1.5mm, and the cattail shell powder, cake and superphosphate are mixed evenly in a weight ratio of 55:41:4, and the pH of the mixture is 6.0 to 6.5 , and add an appropriate amount of water to adjust the moisture content of the mixture to 65%; the cake is selected from peanut cake.

[0033] Step ②, aerobic fermentation

[0034] The mixture and microbial agent I are piled up (stacks with a height of 1m and a width of 2m). After fermentation for 2 to 3 days, when the temperature of the pile rises to 60-70°C, use a turning machine to turn the pile. When the temperature of the pile drops The aerobic fermentation ends at 30-40°C, and the aerobic fermentation time is 9-12 days.

[0035] The weight of the microbial agent I is 0.5% of the mixture (including the added water, the same below), and the colony-forming unit ratio of Aspergillus niger, Sporos...

Embodiment 2

[0042] Step ①, material mixing

[0043] Hickory cattail shells are crushed into cattail shell powder with a particle size of 1.0mm to 1.5mm, and the cattail shell powder, cake and superphosphate are mixed evenly at a weight ratio of 50:45:5, and the pH of the mixture is 6.0 to 7.0 , and add an appropriate amount of water to adjust the moisture content of the mixture to 60%; the cake is selected from soybean cake.

[0044] Step ②, aerobic fermentation

[0045] The mixture and microbial agent I are piled up (stacks with a height of 1m and a width of 2m). After fermentation for 2 to 3 days, when the temperature of the pile rises to 60-70°C, use a turning machine to turn the pile. When the temperature of the pile drops The aerobic fermentation ends at 30-40°C, and the aerobic fermentation time is 9-12 days.

[0046] The weight of microbial inoculum I is 0.5% of mixture, and the colony-forming unit ratio of Aspergillus niger, Thermosporium thermophila, and thermoactinomycetes in ...

Embodiment 3

[0053] Step ①, material mixing

[0054] Hickory cattail shells are crushed into cattail shell powder with a particle size of 1.5mm to 1.8mm, and the cattail shell powder, cake and superphosphate are mixed evenly at a weight ratio of 57:40:3, and the pH of the mixture is 5.5 to 6.5 , and add an appropriate amount of water to adjust the moisture content of the mixture to 70%; the cake is selected from rapeseed cake.

[0055] Step ②, aerobic fermentation

[0056] The mixture and microbial agent I are piled up (stacks with a height of 1m and a width of 2m). After fermentation for 2 to 3 days, when the temperature of the pile rises to 60-70°C, use a turning machine to turn the pile. When the temperature of the pile drops The aerobic fermentation ends at 30-40°C, and the aerobic fermentation time is 9-12 days.

[0057] The weight of microbial inoculum I is 0.5% of mixture, and the colony-forming unit ratio of Aspergillus niger, Thermosporium thermophila, and thermoactinomycetes in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com