Preparation method of core-shell molecular imprinting nano-material, and application of nano-material

A molecular imprinting, core-shell technology, applied in chemical instruments and methods, ion exchange, other chemical processes, etc., can solve the problems of low adsorption capacity, enrichment capacity, and hindering applications, so as to facilitate entry and elution, Effect of Assay Increase, Increased Imprinting Sites, and Adsorption Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

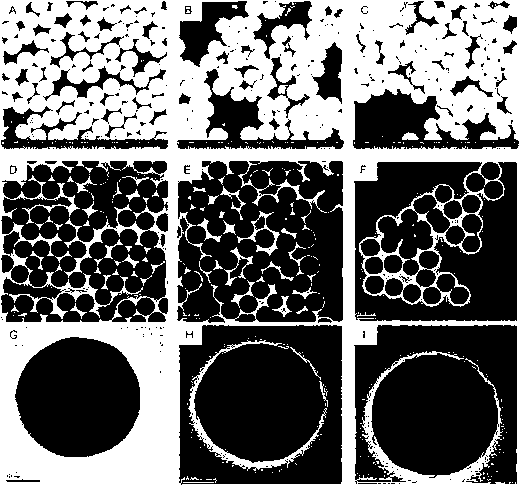

[0029] A method for preparing a core-shell type molecularly imprinted polymer nano silicon sphere, the steps are as follows:

[0030] 1) Synthesis of double bonded nano silicon spheres

[0031] Add 9 mL of tetraethoxysilane to 15 mL of absolute ethanol, 15 mL of distilled water and 3 mL of mixed solvent a with a concentration of 25% ammonia, and stir at 22°C for 24 hours. Then, 1 mL of γ-methacryloxypropyltrimethoxysilane was added to the above solution, and stirred at 22° C. for 48 hours. The resulting solution was centrifuged at 10,000 rpm for 10 minutes, the supernatant was decanted, the product was ultrasonically resuspended and washed with absolute ethanol, and then centrifuged again. Repeat the washing three times in this way, and place the centrifuged product in a vacuum oven to dry at room temperature for 48 hours to obtain double-bonded nano-silicon spheres;

[0032] 2) Synthesis of Assisted Recognition Polymer Chains (ARPCs)

[0033] Add monomer 0.5mL 4-vinylpyrid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com