Trenchless modified polyvinyl chloride pipe and preparation method thereof

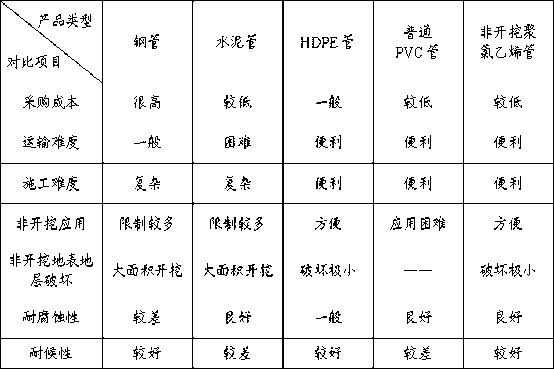

A polyvinyl chloride, non-excavation technology, applied in the direction of rigid pipes, pipes, mechanical equipment, etc., can solve the problems of weather resistance, impact strength ductility, poor environmental protection, etc., to achieve strong weather resistance, reduce use costs, high The effect of impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

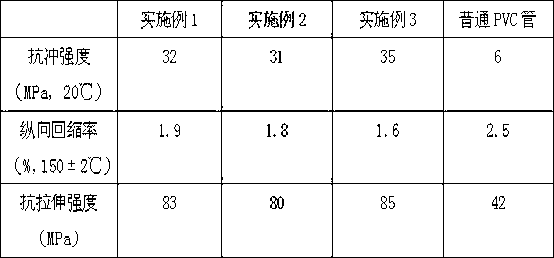

Embodiment 1

[0047] Organotin 1.0

[0048] Acrylic 8

[0049] Silane 0.5

[0050] Dioctyl 0.8

[0051] Titanium dioxide 0.2

[0052] Carbon black 0.1

[0053] 1.2 Preparation method of polyvinyl chloride pipe:

[0054] (1) First heat up and mix the polyvinyl chloride resin;

[0055] (2) When the temperature rises to 45°C, add an organotin stabilizer and continue to heat mix;

[0056] (3) When the temperature rises to 85°C, add modifier, titanium dioxide, and colorant, and continue to heat mix;

[0057] (4) When the temperature rises to 105°C, add dioctyl ester and coupling agent, and continue to heat mix;

[0058] (5) When the heat is mixed to 110°C, keep it for 10 seconds;

[0059] (6) Then cool down and mix to 45°C and discharge;

[0060] (7) The mixture enters the twin-screw extruder for extrusion molding. The host current of the twin-screw extruder is 70A, 18 revolutions, the feeding motor is 70 revolutions, the cavity pressure is >25MPa, and the melt torque is 60%. The...

Embodiment 2

[0065] Organotin 1.5

[0066] Chlorinated polyethylene 9

[0067] Silane 1.2

[0068] Dioctyl 1.5

[0069] Titanium dioxide 0.8

[0070] Carbon black 0.5

[0071] 2.2 Preparation method of polyvinyl chloride pipe:

[0072] (1) First heat up and mix the polyvinyl chloride resin;

[0073] (2) When the temperature rises to 45°C, add an organotin stabilizer and continue to heat mix;

[0074] (3) When the temperature rises to 85°C, add modifier, titanium dioxide, and colorant, and continue to heat mix;

[0075] (4) When the temperature rises to 105°C, add dioctyl ester and coupling agent, and continue to heat mix;

[0076] (5) When the heat is mixed to 110°C, keep it for 60 seconds;

[0077] (6) Then cool down and mix to 45°C and discharge;

[0078](7) The mixture enters the twin-screw extruder for extrusion molding. The host current of the twin-screw extruder is 70A, 18 revolutions, the feeding motor is 70 revolutions, the cavity pressure is >25MPa, and the melt tor...

Embodiment 3

[0083] Organotin 1.2

[0084] Methacrylic acid-butadiene-styrene copolymer 8.4

[0085] Silane 0.9

[0086] Dioctyl 1.2

[0087] Titanium dioxide 0.4

[0088] Carbon black 0.2

[0089] 3.2 Preparation method of polyvinyl chloride pipe:

[0090] (1) First heat up and mix the polyvinyl chloride resin;

[0091] (2) When the temperature rises to 45°C, add an organotin stabilizer and continue to heat mix;

[0092] (3) When the temperature rises to 85°C, add modifier, titanium dioxide, and colorant, and continue to heat mix;

[0093] (4) When the temperature rises to 105°C, add dioctyl ester and coupling agent, and continue to heat mix;

[0094] (5) When heat mixing reaches 110°C, keep it for 30 seconds;

[0095] (6) Then cool down and mix to 45°C and discharge;

[0096] (7) The mixture enters the twin-screw extruder for extrusion molding. The host current of the twin-screw extruder is 70A, 18 revolutions, the feeding motor is 70 revolutions, the cavity pressure is >2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com