Gas-phase rectifying method for steam containing ammonia in APT (ammonium paratungstate) production process and equipment

A production process and ammonia steam technology, applied in the field of gas phase distillation of ammonia-containing steam, can solve the problems of low concentration of recycled ammonia water and low recovery rate of ammonia gas, and achieve the goal of satisfying the balance of ammonia water, reducing the treatment capacity and increasing the concentration of ammonia water Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

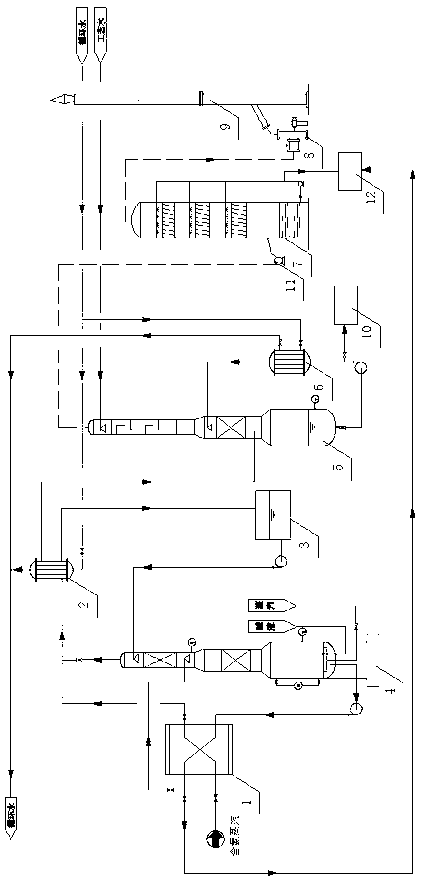

[0032] as attached figure 1 The vapor phase rectification technology of ammonia-containing steam in the shown a kind of APT production process, its step is:

[0033] (1) Ammonia gas absorption cycle: the ammonia-containing steam at 102-107°C from the evaporation and crystallization unit enters the top condenser 2 of the vapor phase rectification tower, and the ammonia-containing vapor is condensed into dilute Ammonia water, dilute ammonia water enters tower top reflux tank 3, meanwhile, the high-concentration ammonia gas that extracts from tower top condenser 2 enters ammonia gas absorption tower 5, and the bottom of ammonia gas absorption tower 5 is provided with absorption liquid, is driven into concentrated ammonia water by pump Condenser 6, after the absorption liquid is condensed, it enters the top of the ammonia gas absorption tower 5, sprays from top to bottom, contacts with the high-concentration ammonia gas produced by the top condenser 2, and the absorption liquid at...

Embodiment 2

[0038] The difference between Example 2 and Example 1 is that in step (1) of Example 2, the ammonia-containing steam passes through the heat exchanger 1 between the tower top condenser, and after the ammonia-containing steam is initially cooled by the heat exchanger, the ammonia-containing steam contains The temperature of the ammonia vapor drops to 60-70°C, and then enters the top condenser 2 for secondary condensation, and the temperature drops to 30-40°C; the low-concentration deammonification wastewater at the bottom of the vapor phase distillation tower 4 also enters the heat exchanger 1 , to lower the temperature of the ammonia-containing steam; in addition, in step (2), the liquid caustic soda added at the bottom of the gas-phase rectification tower 4 is 30% NaOH, and the pH of dilute ammonia water at the bottom of the tower is adjusted to be >14; When the concentration of ammonia nitrogen in the deamination wastewater is less than 100 mg / L, it is sent to the nitrogen st...

Embodiment 3

[0040] A kind of equipment for the gas phase rectification method of embodiment 1 or embodiment 2, it is characterized in that each part and connection relation are: the steam pipeline containing ammonia is connected with the tower top condenser 2 inlet of gas phase rectification tower, and described tower The top condenser 2 top outlet is connected with the ammonia absorption tower 5 inlets, and the bottom of the ammonia absorption tower 5 is connected with the bottom end of the strong ammonia water condenser 6 and the ammonia water tank 10 through a pump, and the top of the strong ammonia water condenser 6 is connected with the ammonia water tank 10. The middle part of the gas absorption tower 5 is connected; the bottom outlet of the tower top condenser 2 is connected to the top of the gas phase rectification tower 4 through the tower top reflux tank 3, and the bottom of the gas phase rectification tower 4 is connected with an alkali injection device and steam Injection devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com