Hydrocracking catalyst containing mesoporous-microporous molecular sieve and preparation method of catalyst

The technology of microporous molecular sieve and mesoporous molecular sieve is applied in the field of hydrocracking catalyst and its preparation, which can solve the problem of low quality of tail oil, and achieve the effects of low BMCI value, high activity and high selectivity of tail oil.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Dissolve 925g of water glass and 230g of sodium hydroxide in water, and stir. Weigh about 180g of aluminum sulfate octadecahydrate crystals, dissolve it in 400mL of water, and add it to the flask. Stir for 40 minutes. Put it in a 60°C water bath and age for 12 hours.

[0035] Weigh about 200g of P123 and dissolve it in 7500mL of water. Stir in a water bath at 25°C. Add 30 mL of 6 mol / L sulfuric acid solution, adjust the pH to about 1.5, and continue stirring.

[0036] Weigh about 1500g of aging solution, add 30ml of 6mol / L sulfuric acid solution, and assemble for 20 hours. Move to a Teflon-lined crystallization kettle, crystallize at 120°C for 24 hours, wash and filter, and dry at 80°C for 5 hours. Baking at 550°C for 4 hours. The number is MEY-1.

Embodiment 2

[0038] Dissolve 500g of sodium silicate and 200g of sodium hydroxide in water and stir. Weigh about 100g of sodium metaaluminate, dissolve it in 400mL of water, and add it to the flask. Stir for 40 minutes. Put it in a 90°C water bath and age for 10 hours.

[0039] Weigh about 300g of P123 and dissolve it in 7500mL of water. Stir in a water bath at 25°C. Add 30 mL of 6 mol / L sulfuric acid solution, adjust the pH to about 1.5, and continue stirring.

[0040] Weigh about 1000g of aging solution, add 20ml of 6mol / L sulfuric acid solution, and assemble for 20 hours. Move to a Teflon-lined crystallization kettle, crystallize at 120°C for 24 hours, wash and filter, and dry at 80°C for 5 hours. Baking at 550°C for 4 hours. The number is MEY-2.

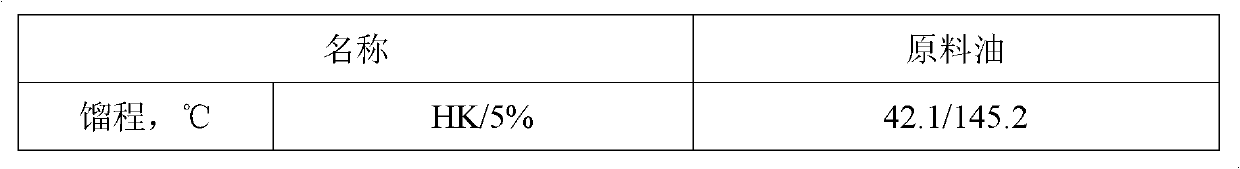

[0041] The properties of the mesoporous molecular sieves synthesized in Example 1 and Example 2 are shown in Table 1.

Embodiment 3

[0043] 102g MEY-1 molecular sieve (dry basis 98.3wt%), 83.5g macroporous alumina (pore volume 1.20ml / g, specific surface 267.8m 2 / g, dry basis 71.85wt%), 160 grams of binding agent (dry basis 25wt%, the mass ratio of nitric acid and small-pore alumina is 15%) and 4g safflower powder add in the roller compactor and mix and grind, add water, grind Press into a paste, extrude into strips, dry at 120°C for 4 hours after extrusion, and then bake in a muffle furnace at 550°C for 4h to obtain a carrier.

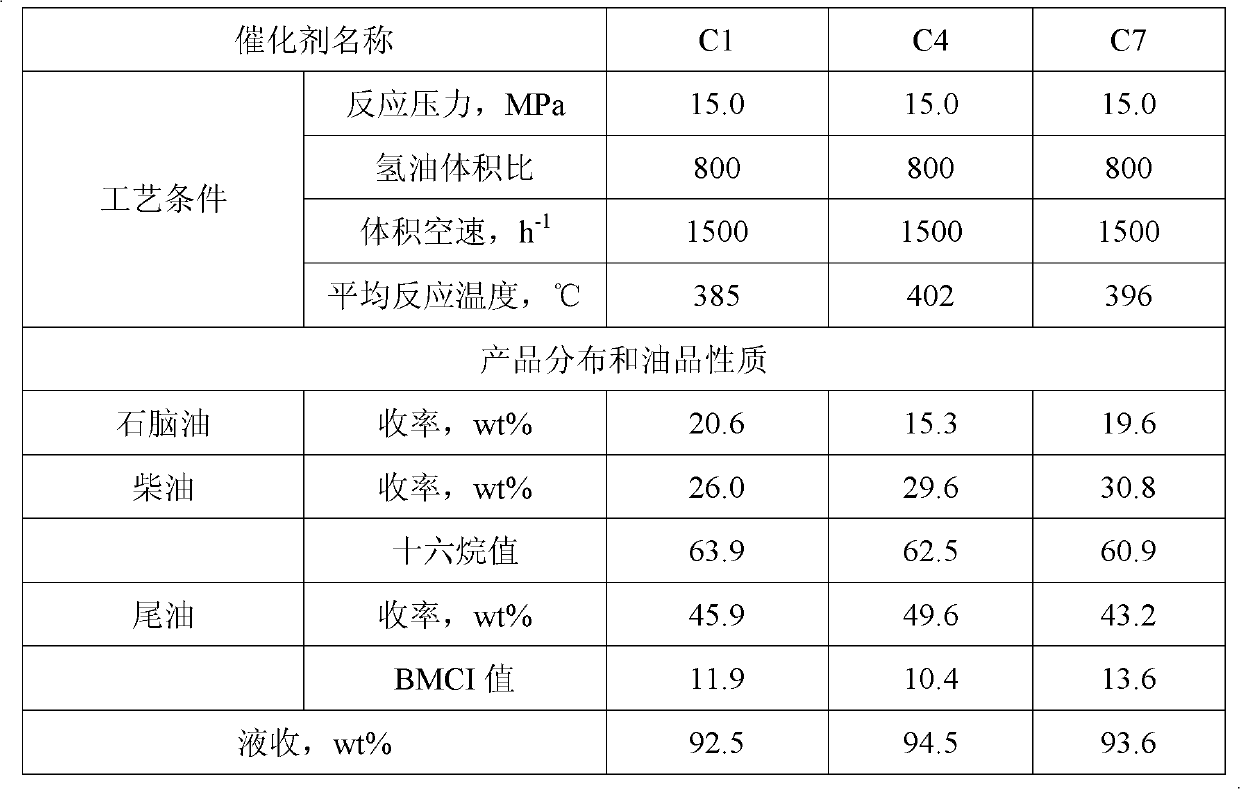

[0044] Weigh 50 g of the prepared carrier, prepare a certain amount of impregnation solution containing tungsten and nickel, and impregnate with equal volume. Precipitate for 2 hours, dry at 120°C for 4 hours, and then calcinate in a muffle furnace at 550°C for 4 hours to obtain catalyst C1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore volume | aaaaa | aaaaa |

| Specific surface | aaaaa | aaaaa |

| Specific surface | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com