Nitrogen-doped graphene nanoribbon and preparation method thereof

A nitrogen-doped graphene and nanoribbon technology, applied in the field of materials, can solve the problems of complex preparation methods of graphene nanoribbons, high toxicity of reagents, harsh synthesis conditions, etc., and achieve increased reactivity, simplified preparation methods, and scientific preparation methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The invention discloses a method for preparing nitrogen-doped graphene nanobelts. The method firstly synthesizes nitrogen-doped iron-filled carbon nanotubes with unique composition and structure, and then uses oxidizing strong acid as an oxidant to oxidize nitrogen-doped iron-filled carbon nanotubes. , to prepare nitrogen-doped graphene nanobelts. Specifically, the preparation method of nitrogen-doped graphene nanoribbons comprises the following steps:

[0039] (1) Place two containers containing carbon source and catalyst precursor respectively in a quartz tube reactor with gas inlet and gas outlet at both ends, and make the two containers close to the gas inlet so that the The incoming inert protective gas can carry volatilized materials into the middle of the quartz tube reactor to participate in the reaction. It can be understood that in addition to the quartz tube reactor, the present invention can also adopt other forms of high temperature resistant tubular react...

Embodiment 1

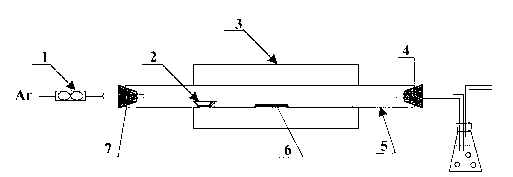

[0051] image 3 It is the reaction device used to prepare nitrogen-doped iron-filled carbon nanotubes in Example 1; Figure 4 Be the scanning electron micrograph of the nitrogen-doped iron-filled carbon nanotube prepared in embodiment 1; Figure 5 The transmission electron micrograph of the nitrogen-doped iron-filled carbon nanotubes prepared in Example 1; Image 6 Be the scanning electron micrograph of the nitrogen-doped graphene nanobelt prepared in embodiment 1; Figure 7 It is a transmission electron micrograph of the nitrogen-doped graphene nanoribbons prepared in Example 1.

[0052] This embodiment discloses a preparation method of nitrogen-doped graphene nanoribbons, using image 3 The shown iron-filled carbon nanotube reaction device includes: a tubular resistance furnace 3 with a temperature control device, two porcelain boats 2 for holding solid reactants, and gas inlets 7 and 2 respectively at both ends. The quartz tube reactor 5 of the gas outlet 4, the porcela...

Embodiment 2

[0060] Figure 8 It is a scanning electron micrograph of the nitrogen-doped graphene nanoribbons prepared in Example 2.

[0061] Weigh 100 mg of nitrogen-doped iron-filled carbon nanotubes prepared in Example 1, place them in a flask filled with nitric acid with a volume of 100 ml and a mass percentage of 65 wt%, and ultrasonically disperse the carbon nanotubes for 5 min. Heat to 120 in an oil bath o C, reflux for 0.5 h. After completion of the reaction, cool to room temperature, pour the solution into 500 ml deionized water, filter, wash the sample to neutrality, and place in a vacuum oven at 120 o C dried for 12 h to prepare nitrogen-doped graphene nanoribbons (the product is labeled as N-GNRs-2).

[0062] Nitrogen-doped graphene nanoribbons were observed using a scanning electron microscope (SEM), as Figure 8 As shown, the obtained sample has an obvious two-dimensional band structure, and its length can reach more than ten microns. It shows that the nitrogen-doped iro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com