Preparation method of germanium nanotubes

A technology of nanotubes and working electrodes, applied in the field of preparation of germanium nanotubes, can solve the problems of inability to realize, difficult to operate, complicated equipment, etc., and achieves the effects of convenient operation, wide electrochemical window and high safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

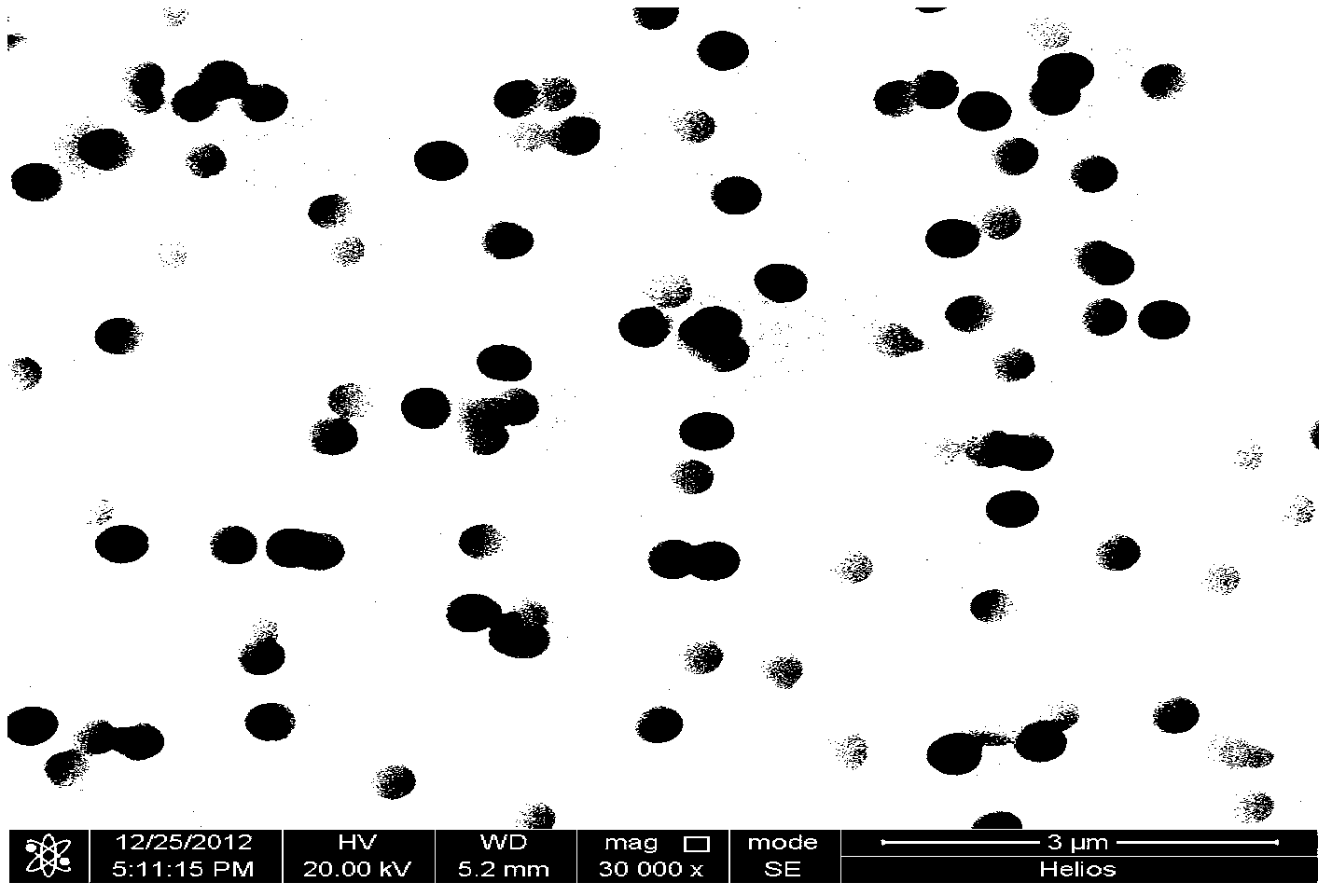

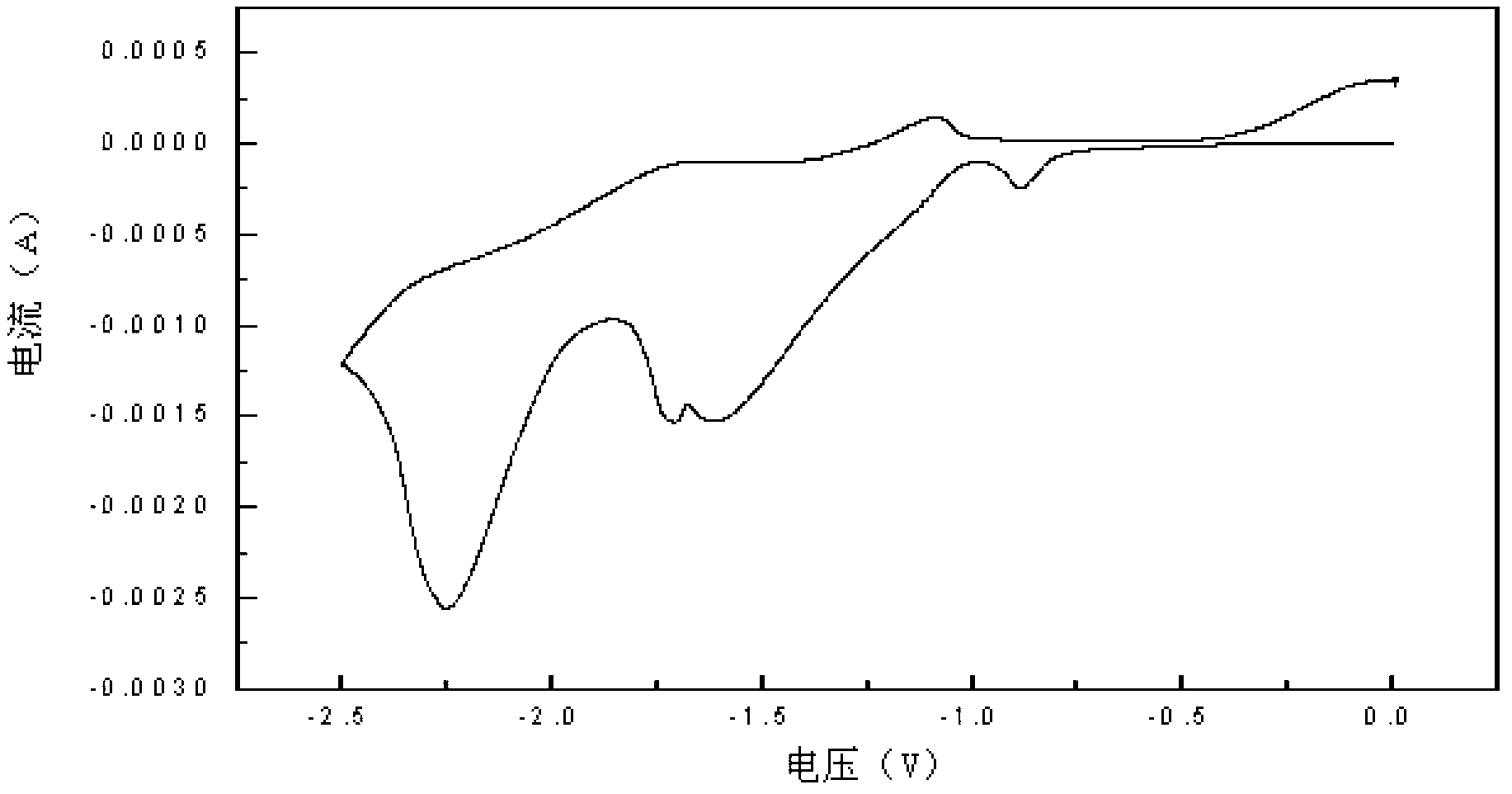

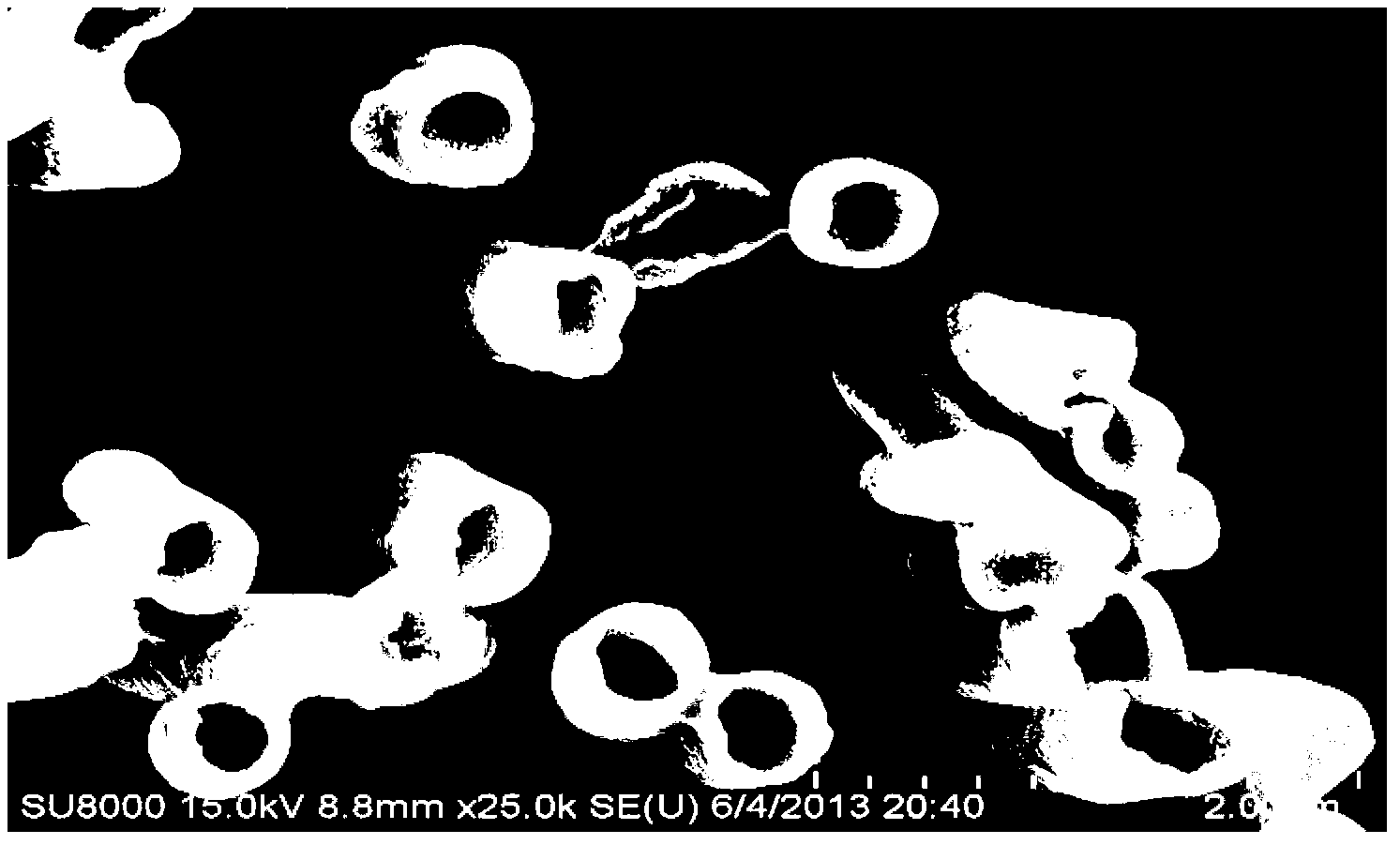

[0019] Specific embodiment one: the preparation method of a kind of germanium nanotube of this embodiment is specifically carried out according to the following steps:

[0020] 1. Select a polycarbonate porous membrane with a diameter of 13 mm to 25 mm, a thickness of 6 μm to 11 μm, and a pore diameter of 200 nm to 3 μm, and use ion sputtering to sputter gold with a thickness of 160 nm to 500 nm on the dark side of the polycarbonate porous membrane. Prepare a working electrode with gold-plated electrodeposited germanium nanotubes at one end, and attach the gold-plated end of the working electrode to the conductive substrate with a conductive slurry;

[0021] Second, in H 2 O and O 2 Under the condition that the content is less than 1ppm, the GeCl 4 Add it into the ionic liquid 1-methyl-3-ethylimidazole bistrifluorosulfonic acid ammonium salt solvent, dissolve and shake well, and then let it stand for 24 hours to prepare an electrolyte solution with a concentration of 0.01-0....

specific Embodiment approach 2

[0024] Embodiment 2: This embodiment differs from Embodiment 1 in that: in step 1, the conductive substrate is copper foil, nickel sheet, indium tin oxide or fluorine-doped tin oxide. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0025] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the thickness of gold in step 1 is 200nm-400nm. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com