A method of manufacturing a wire-wound power inductive element

A power inductor and component manufacturing technology, applied in coil manufacturing, electrical components, inductor/transformer/magnet manufacturing, etc., can solve the problems of low saturation magnetic flux density and low space utilization, and achieve low DC impedance, high current, Simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

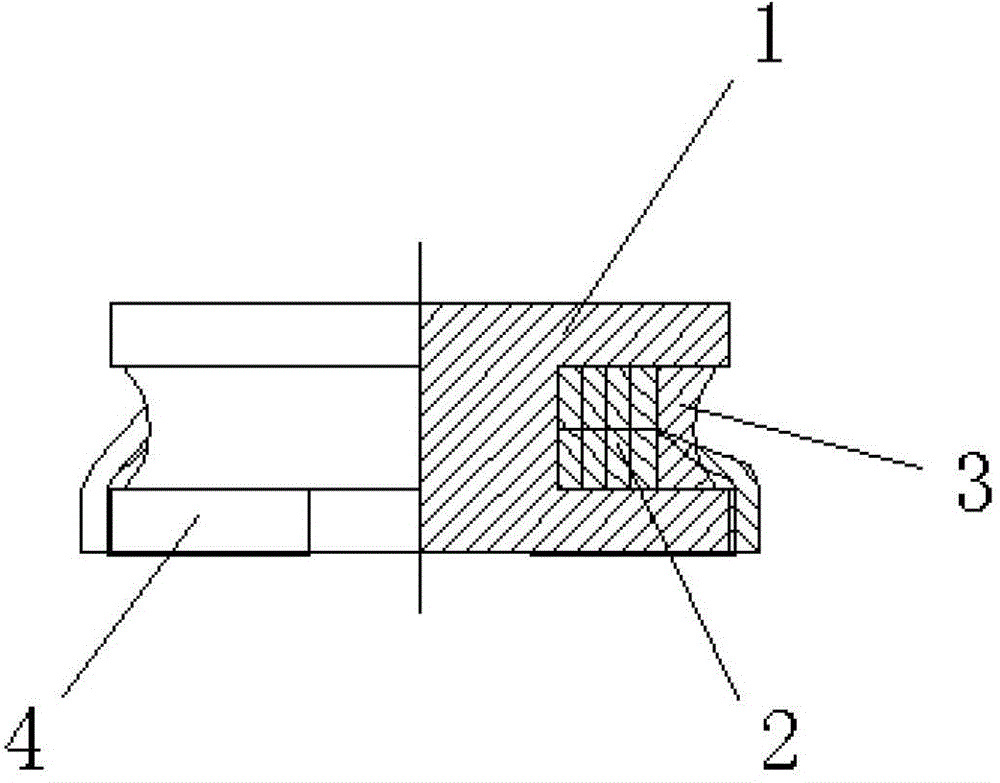

[0073] a kind of like Figure 1~3 The wire-wound power inductive element shown is an I-shaped wire-wound glue-coated power inductive element, which includes an I-shaped magnetic core 1 , a coil winding and an adhesive layer 3 on the surface.

[0074] The I-shaped magnetic core 1 is a magnetic core made of iron-silicon-chromium (FeSiCr) alloy powder with a particle size of 5 μm to 15 μm produced by the commercially available water atomization method, and its saturation magnetic flux density is significantly higher than that of the currently used nickel-zinc-iron The oxygen core can increase the saturation current of the power inductive element as much as possible under the condition that the inductance value of the power inductive element is constant.

[0075] The coil winding is a pair-wound flat enameled wire winding 2 made of a flat wire pair-wound method. In the limited and predetermined winding space required for miniaturization, wires with a larger conductor cross-section...

specific Embodiment approach 2

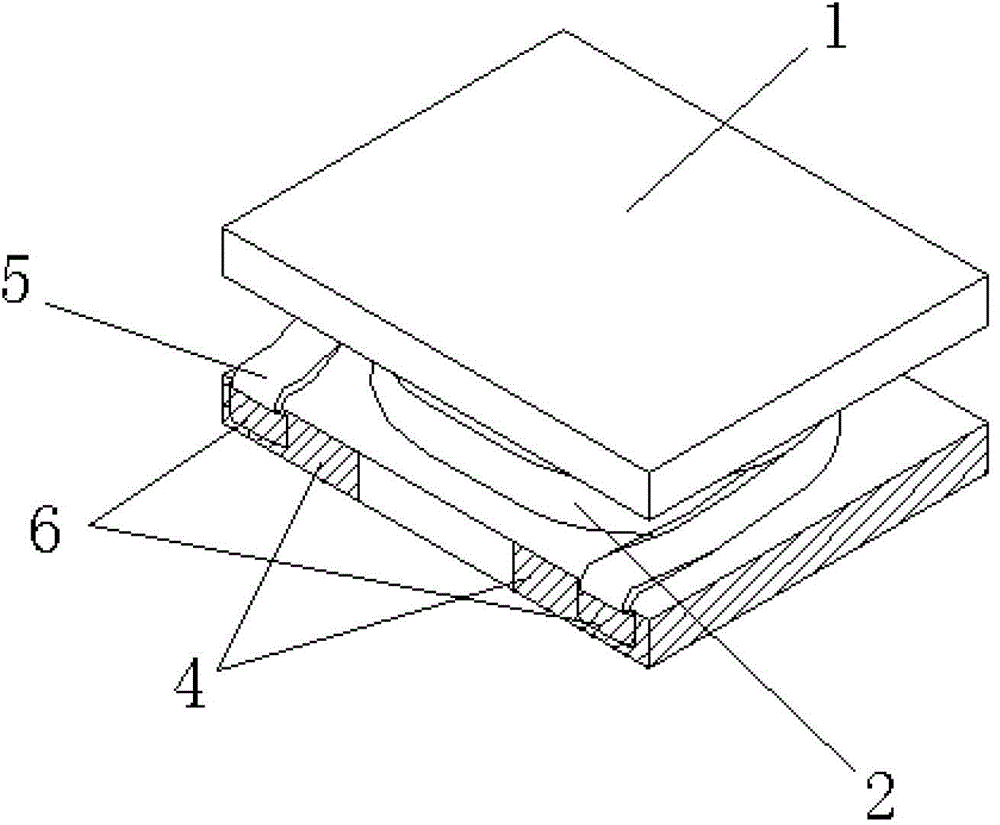

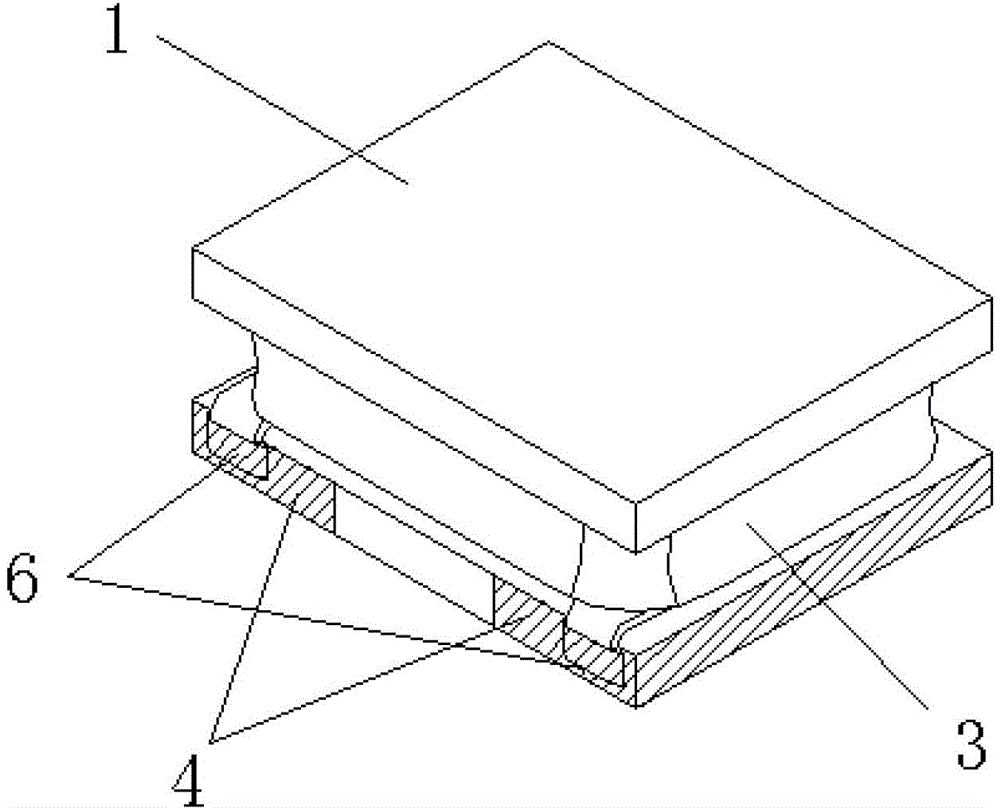

[0097] a kind of like figure 1 , 4 The wire-wound power inductive element shown in ~5 is basically the same as the specific embodiment 1, the difference lies in the following differences in its manufacturing method:

[0098] Step 2) The way of making the winding to wind the flat enameled wire winding is that the wire tail is close to the long side of the L-shaped sputtering metallization layer.

[0099] Step 3) Ultrasonic welding is used for the welding electrode, which is to weld and connect the tail of the flat enameled wire winding with the welding point on the long side of the L-shaped metallization layer to form an electrode.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com