Photoelectrocatalytic film, preparation method and application

A photoelectric catalysis and thin film technology, which is applied in chemical instruments and methods, electrochemical water/sewage treatment, physical/chemical process catalysts, etc., can solve problems such as composite thin films that have not yet appeared, and achieve improved charge transport properties, large surface area, increased The effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

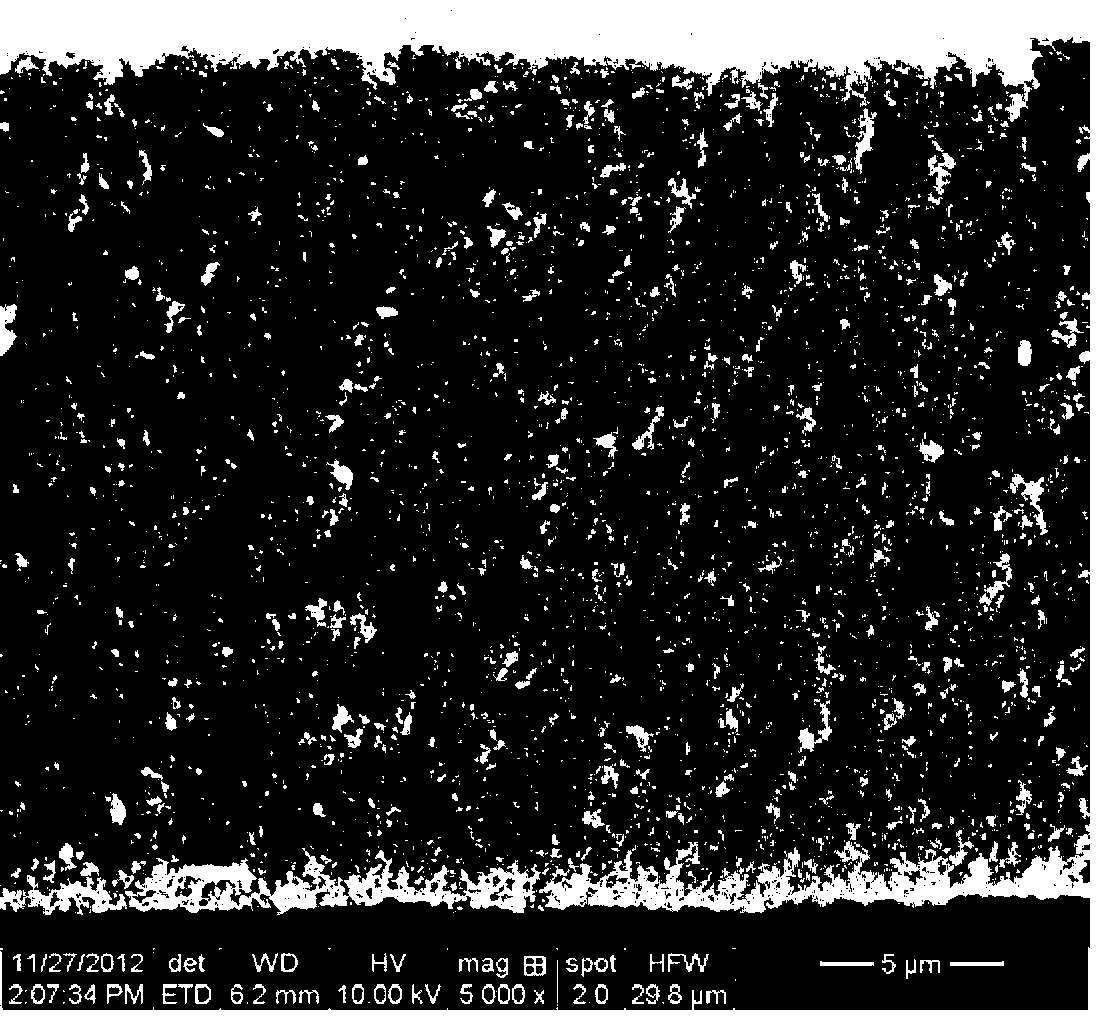

[0031] Embodiment 1: The photoelectrocatalytic thin film provided in this embodiment, it obtains mixed slurry by uniform mixing of conductive nano-oxide slurry and titanium dioxide slurry in proportion, it is coated on titanium plate and carries out scraping coating to form uniform coating Afterwards, the mixed slurry coating is sintered to obtain the photoelectrocatalytic thin film.

[0032] The conductive nano oxide slurry is prepared by mixing conductive nano oxide, ethyl cellulose and terpineol in a mass ratio of 2:1:7.

[0033] The conductive nano-oxide is one of antimony tin oxide ATO, indium tin oxide ITO and fluorine-doped tin dioxide FTO, the particle size range of the conductive nano-oxide is 15-100 nm, and the resistance range is 0.1Ω-100Ω.

[0034] The titanium dioxide slurry is prepared by mixing titanium dioxide, ethyl cellulose and terpineol in a mass ratio of 2:1:7.

[0035] The titanium dioxide is pure anatase or mixed crystal titanium dioxide of rutile and a...

Embodiment 2

[0048] Embodiment 2: The photocatalytic thin film provided in this embodiment, the preparation method and application of the photocatalytic thin film, its components and steps are basically the same as in Example 1, the difference is:

[0049] A kind of photoelectrocatalytic thin film, it is mixed crystal titanium dioxide (average particle diameter: 10nm) slurry by conductive nano-oxide slurry and rutile and anatase, according to conductive nano-oxide slurry and rutile and anatase The mass ratio of the mixed crystal titanium dioxide slurry is mixed at a ratio of 0:1, and then the resulting slurry is scraped on a titanium plate and then sintered.

[0050] The preparation method of above-mentioned photoelectrocatalytic thin film, it comprises the following steps:

[0051] (1) Preparation of titanium dioxide slurry: take by weight the mixed crystal form of rutile and anatase, ethyl cellulose and terpineol respectively in a mass ratio of 2: 1: 7; the weighed rutile and anatase Mi...

Embodiment 3

[0056] Embodiment 3: The photocatalytic thin film provided in this embodiment, the preparation method and application of the photocatalytic thin film, its components and steps are basically the same as those in Examples 1 and 2, except that:

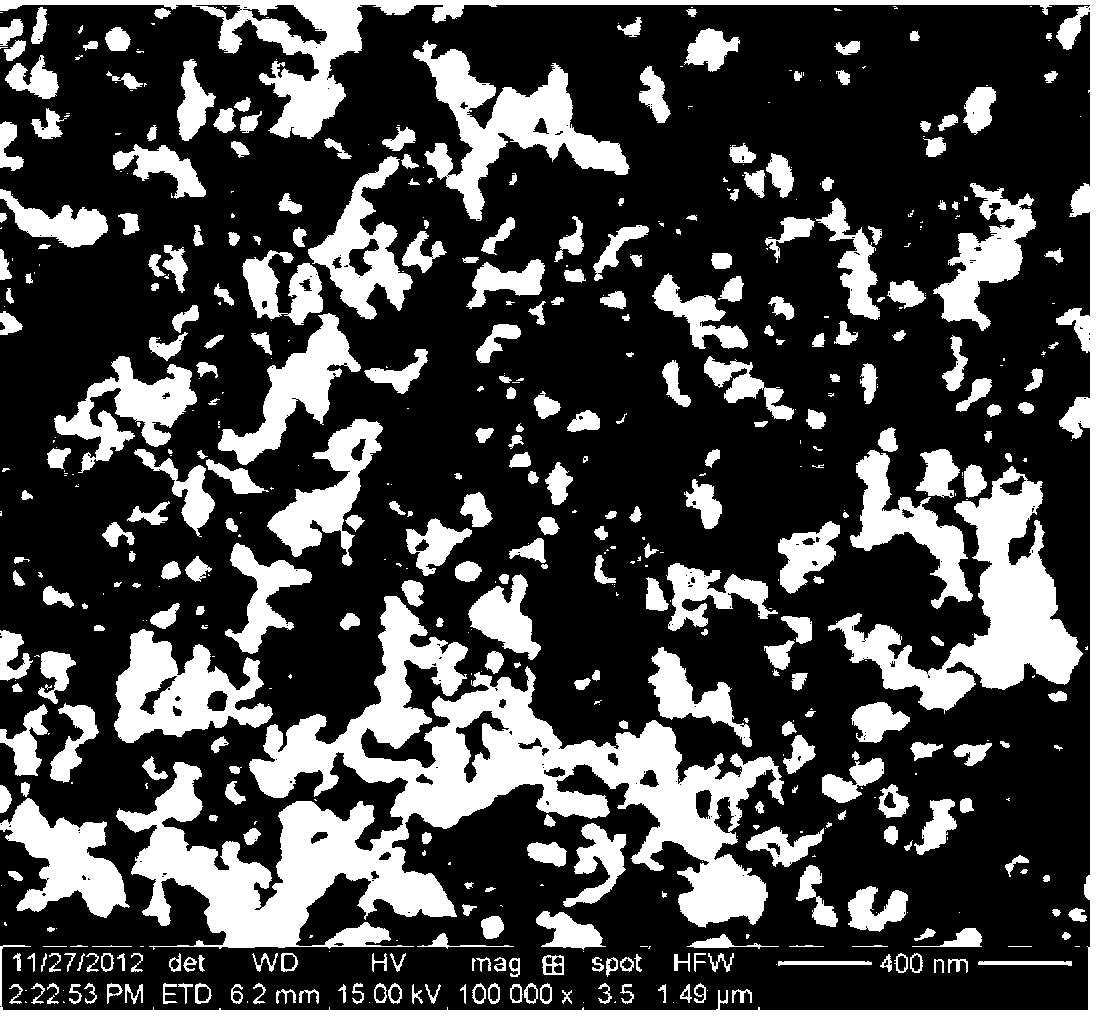

[0057] A kind of photoelectrocatalytic thin film, it is by the mixed crystal type titanium dioxide slurry of indium tin oxide ITO (particle size 15nm, sheet resistance 0.1Ω) slurry and rutile and anatase, by indium tin oxide ITO slurry and rutile and The anatase mixed crystal titanium dioxide slurry is mixed in a mass ratio of 0.05:1, and then obtained by scraping and sintering the obtained slurry on a titanium plate.

[0058] The preparation method of above-mentioned photoelectrocatalytic thin film, it comprises the following steps:

[0059] (1) Preparation of indium tin oxide ITO slurry: weigh indium tin oxide ITO, ethyl cellulose and terpineol respectively in a mass ratio of 2:1:7; grind the indium tin oxide ITO to make it uniformly d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com