Adhesives and Adhesive Sheets

A technology of adhesives and thin sheets, applied in the direction of adhesive types, ester copolymer adhesives, adhesives, etc., can solve the problems of low concentration, difficult to thick adhesive layer, etc., and achieve high workability and good workability , the effect of improving mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

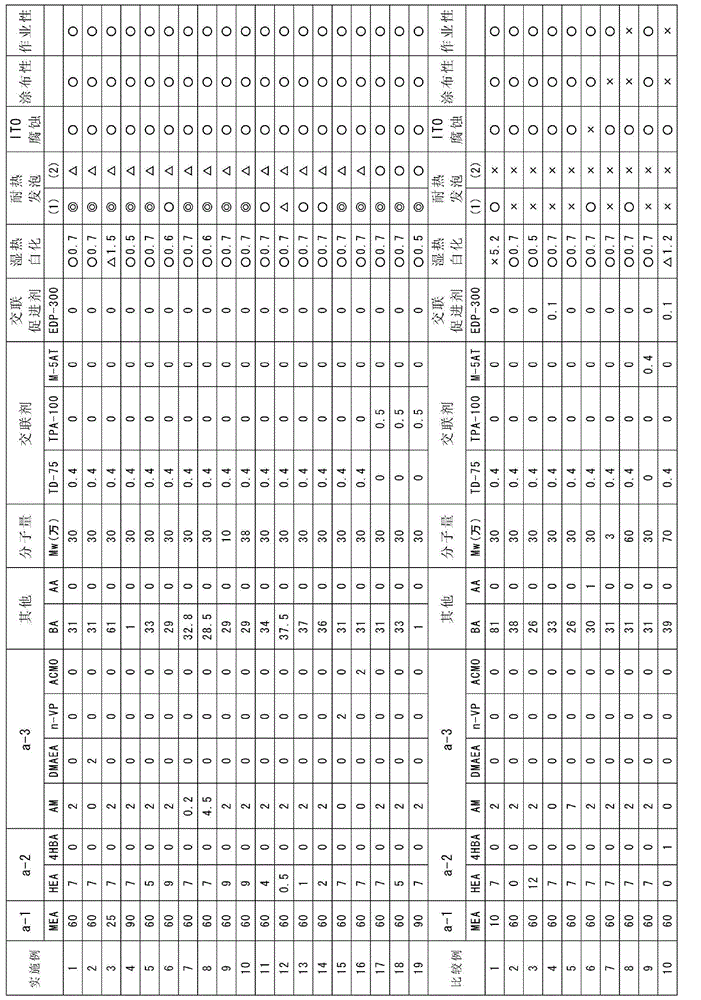

Examples

Embodiment 1

[0045] Manufacture of adhesive sheets:

[0046] In a reaction device equipped with a stirrer, a reflux cooler, a thermometer, and a nitrogen introduction pipe, 60 parts by mass of methoxyethyl acrylate (MEA), 31 parts by mass of butyl acrylate (BA), and 5 parts by mass of acrylic acid 2-hydroxyethyl ester (HEA), 2 parts by mass of acrylamide (AM), 100 parts by mass of methyl ethyl copper (MEK), and 0.1 part by mass of 2,2'-azobisisobutyronitrile, And the air in the reaction container was replaced with nitrogen. Next, the temperature was raised to 70° C. while stirring under a nitrogen atmosphere, and thereafter, the reaction was performed for 5 hours. After the reaction, the mixture was diluted with methyl ethyl ketone until the concentration of non-volatile components was 40% by mass, thereby obtaining a (meth)acrylic polymer solution.

[0047] With respect to 100 parts by mass of the solid content of the (meth)acrylic polymer solution obtained above, 0.4 parts by mass of a...

Embodiment 2

[0049] Manufacture of adhesive sheets:

[0050] In Example 1, except that HEA was changed to 7 parts by mass and AM was changed to 2 parts by mass of diethylaminoethyl acrylate (DMAEA), an adhesive was produced in the same manner as in Example 1. and adhesive sheets.

Embodiment 3

[0052] Manufacture of adhesive sheets:

[0053] In Example 1, except that MEA was changed to 25 parts by mass, HEA was changed to 7 parts by mass, and BA was changed to 61 parts by mass, the adhesive and bonding agent were produced in the same manner as in Example 1. Flakes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com