Mesoporous molecular sieve catalyst and preparation method thereof

A technology of mesoporous molecular sieves and catalysts, applied in the direction of molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., to achieve the effects of improved selectivity, reduced cracking reactions, high olefin oligomerization activity and diesel yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1, preparation catalyst Na / MSU-S MFI

[0034] (1) Dissolve 5.81g of hexamethylenediamine in 41.27g of deionized water, add 40g of silica sol (containing 30% SiO 2 ), configured as solution A, dissolved 0.55g sodium metaaluminate and 1.18g NaOH in 14.25g deionized water to form solution B, added solution B dropwise to solution A while stirring, and filled the obtained solution into 100ml In a closed autoclave, hydrothermal crystallization was carried out at 50°C for 1 day to obtain MFI seed crystals.

[0035] (2) Dissolve 18.22g of cetyltrimethylammonium bromide (CTAB) in 130g of deionized water, heat in a 40°C water bath until the solution is clear, add the MFI seed crystal prepared in step (1) while stirring, and then With 2.0M H 2 SO 4 The pH value of the solution was quickly adjusted to 9.0, and after stirring for 2 hours, it was loaded into a stainless steel reactor lined with polytetrafluoroethylene, and the temperature was raised from room temperatu...

Embodiment 2

[0042] Embodiment 2, preparation catalyst ZrNa / MSU-S MFI

[0043] (1) Prepare Na / MSU-S according to the method in Example 1 MFI sample.

[0044] (2) Weigh a certain amount of formed Na / MSU-S MFI Molecular sieves were impregnated in zirconium nitrate solution and evacuated to dryness. After drying at 120 °C for 3 h, the dried catalyst was put into a muffle furnace and calcined at 500 °C for 4 h to obtain the modified ZrNa / MSU-S MFI Molecular sieve catalyst, the weight percent content of Zr in the catalyst is 1.0wt%, Na + The content of 0.38wt%, Na / MSU-S MFI The content of aluminum oxide is 79wt%, and the content of alumina is 20wt%.

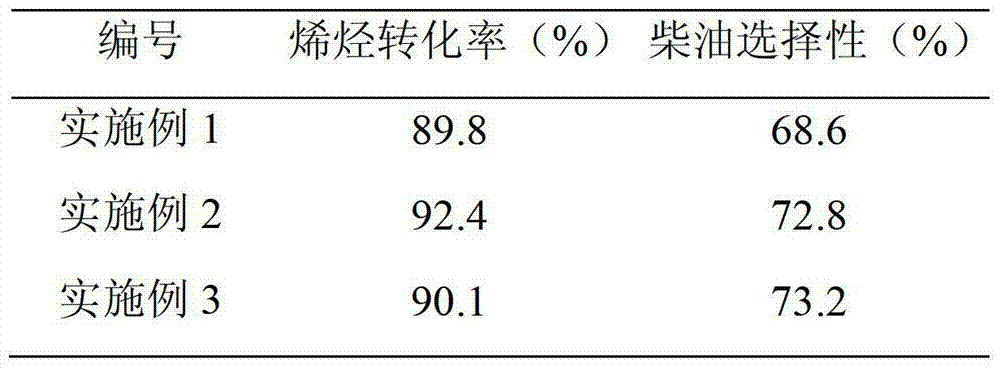

[0045] The catalyst prepared by this embodiment is used for olefin oligomerization, at N 2 Under the condition of existence, the process conditions of olefin oligomerization reaction in Fischer-Tropsch synthesis LPG (the composition is the same as that in Example 1) are as follows: operating pressure is 4.0MPa, reaction temperature is 250°C...

Embodiment 3

[0047] Embodiment 3, preparation catalyst LaZrNa / MSU-S MFI

[0048] (1) Prepare Na / MSU-S according to the method in Example 1 MFI sample.

[0049] (2) Weigh a certain amount of formed Na / MSU-S MFI Molecular sieves are impregnated in a mixed solution of zirconium nitrate and lanthanum nitrate, and evacuated to dryness. After drying at 120 °C for 3 h, the dried catalyst was put into a muffle furnace and calcined at 500 °C for 4 h to obtain the modified LaZrNa / MSU-S MFI Molecular sieve catalyst, the weight percentage content of Zr and La in the catalyst is 1.0wt%, Na + The content is 0.37wt%, Na / MSU-S MFI The content of aluminum oxide is 78wt%, and the content of alumina is 20wt%.

[0050] The catalyst prepared by this embodiment is used for olefin oligomerization, at N 2 Under the condition of existence, the process conditions of olefin oligomerization reaction in Fischer-Tropsch synthesis LPG are: operating pressure is 4.0MPa, reaction temperature is 250℃, N 2 The / olef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com