Method for obtaining sulfur from sulfur compounds in coal chemical plant and electric power plant

A technology of sulfide and coal chemical industry, applied in the direction of sulfur preparation/purification, etc., can solve the problems of low economic value of recovered products, high total emission, and poor performance, etc., and achieve low construction cost and high sulfur recovery efficiency High, no secondary pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

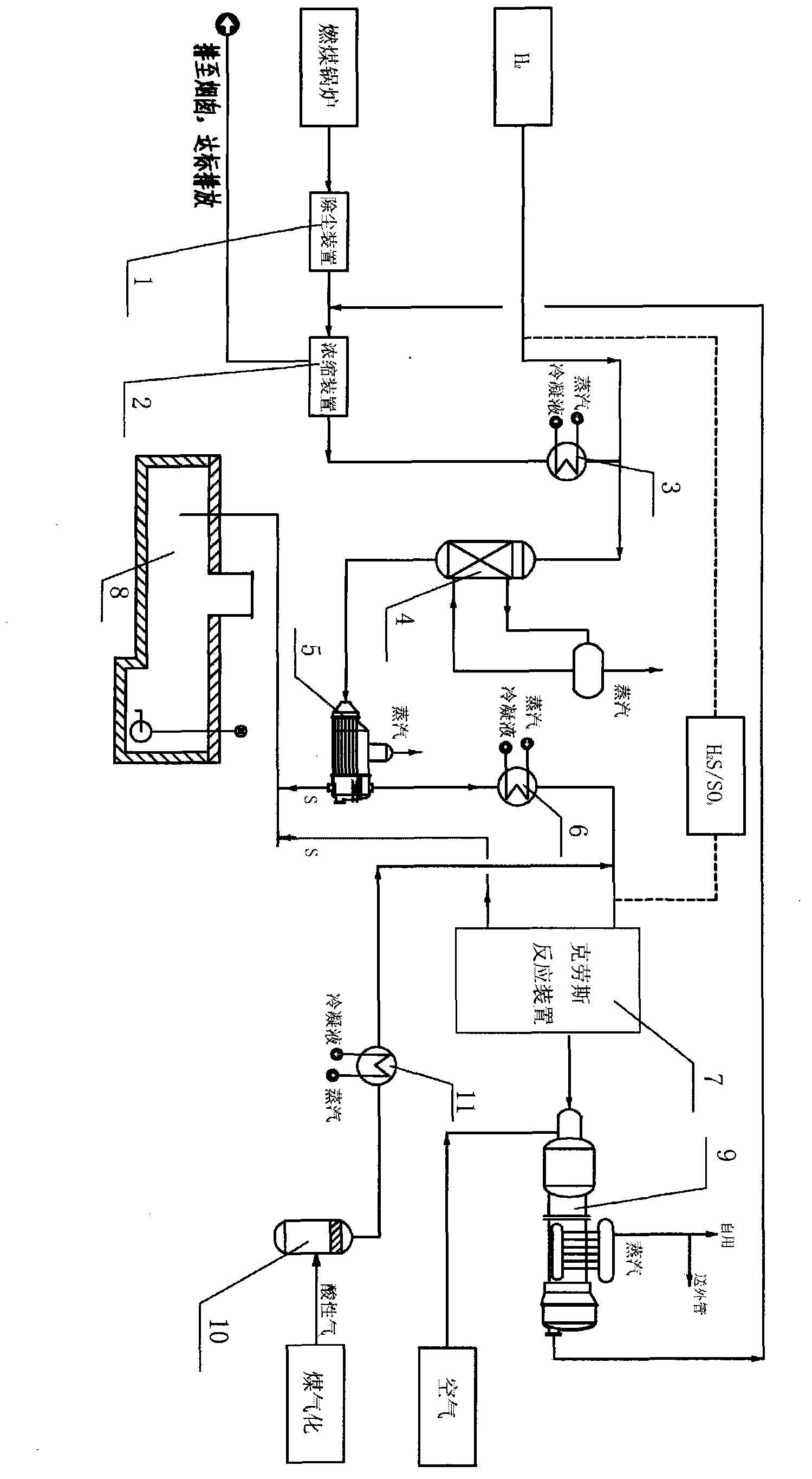

[0029] Example 1: as figure 1 As shown, the present invention comprises the following steps:

[0030] (1) The flue gas from the coal-fired boiler system passes through the dust removal device 1 and then enters the concentration device 2 for concentration treatment to increase the content of sulfur dioxide in the flue gas.

[0031] (2) The concentrated flue gas is heated by the flue gas preheater 3 and then enters the constant temperature selective reduction reactor 4, and the additional hydrogen is used as a reducing agent to react under the action of the selective reduction catalyst to generate elemental sulfur, The chemical equation is:

[0032] H 2 +SO 2 =S+H 2 O ①

[0033] The heat of the 2.1-2.6MPaG steam generated by the reaction is taken away by the cooling coil arranged in the thermostatic selective reduction reactor 4, so that the temperature of the thermostatic selective reduction reactor 4 is maintained at about 230°C.

[0034] (3) The catalytically reduced fl...

Embodiment 2

[0036] Embodiment 2: The difference from Embodiment 1 is:

[0037] In the step (3), what enters the Claus reaction device 7 also includes preheated coal gasification acid gas, and the acid gas enters the acid gas preheater 11 after gas separation in the acid gas separation tank 10 After heating, it enters the Claus reaction device 7 .

Embodiment 3

[0038] Example 3: The difference from Example 1 is:

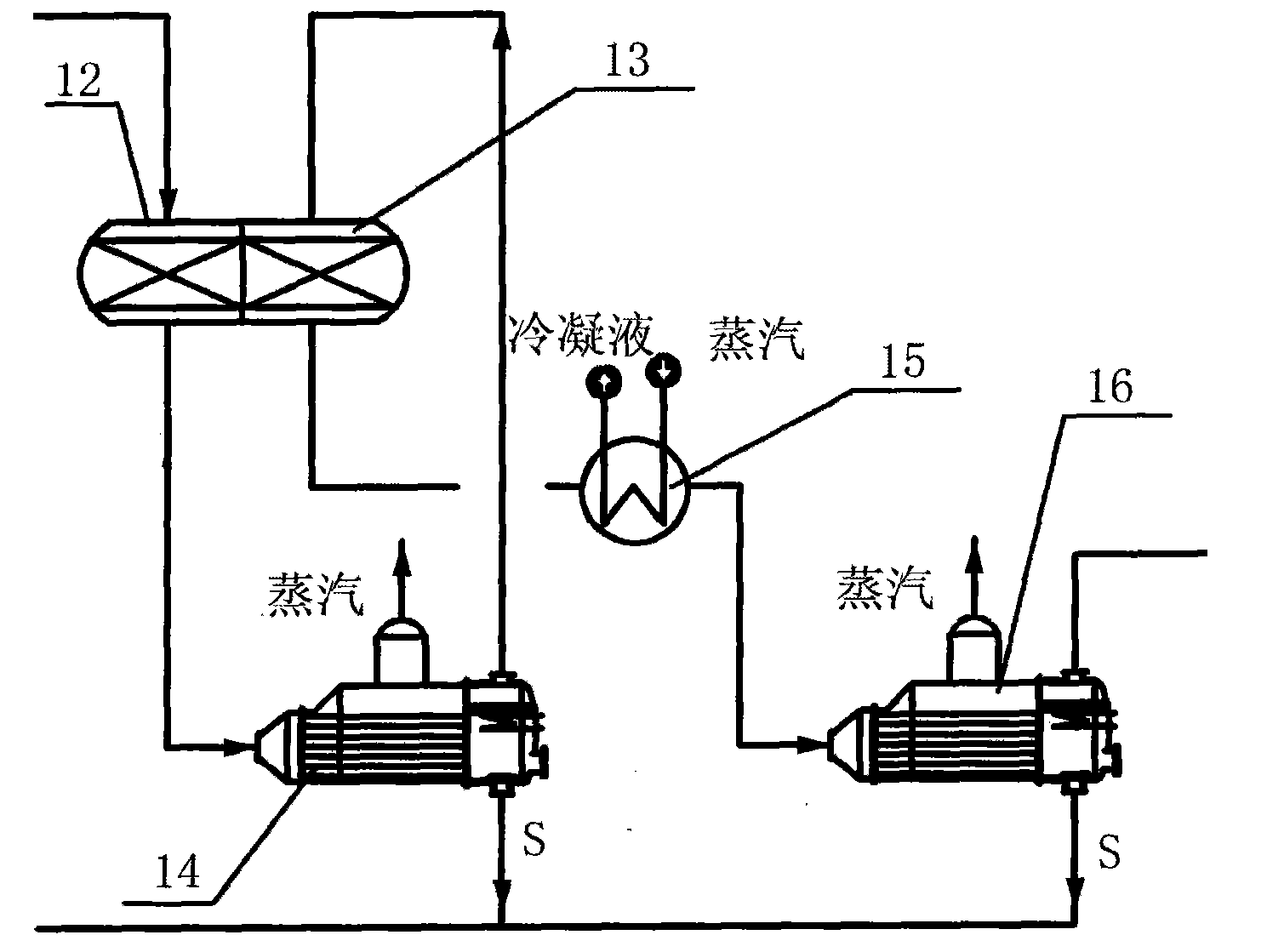

[0039] The Claus reaction device 7 includes a primary Claus reactor 12, a secondary Claus reactor 13, a primary sulfur condenser 14, a secondary sulfur condenser 15 and a secondary reheater 16; The first-stage Claus reactor 12 and the second-stage Claus reactor 13 are filled with high-efficiency and active catalysts, and the catalytically reduced flue gas first enters the first-stage Claus reactor 12 for catalytic reaction, and then enters a first-stage Claus reactor 12 for catalytic reaction. The secondary sulfur condenser 14, the liquid sulfur that is removed enters the liquid sulfur pool and the flue gas enters the secondary Claus reactor 13 to continue the catalytic reaction, and the flue gas after the secondary catalytic reaction enters the secondary reheater 16 and then enters the secondary sulfur Condenser 15, the liquid sulfur removed by condensation treatment enters the liquid sulfur pool 8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com