Method of preparing hydroxylamine salt by using reaction-extractive distillation coupling technology

A technology of extractive distillation and hydroxylamine salt, which is applied in the preparation of hydroxylamine, carboxylate, nitrogen and non-metallic compounds, etc., can solve the problems of low product yield, poor safety, and poor feasibility, and achieves high product yield and reaction safety. , The effect of low material toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

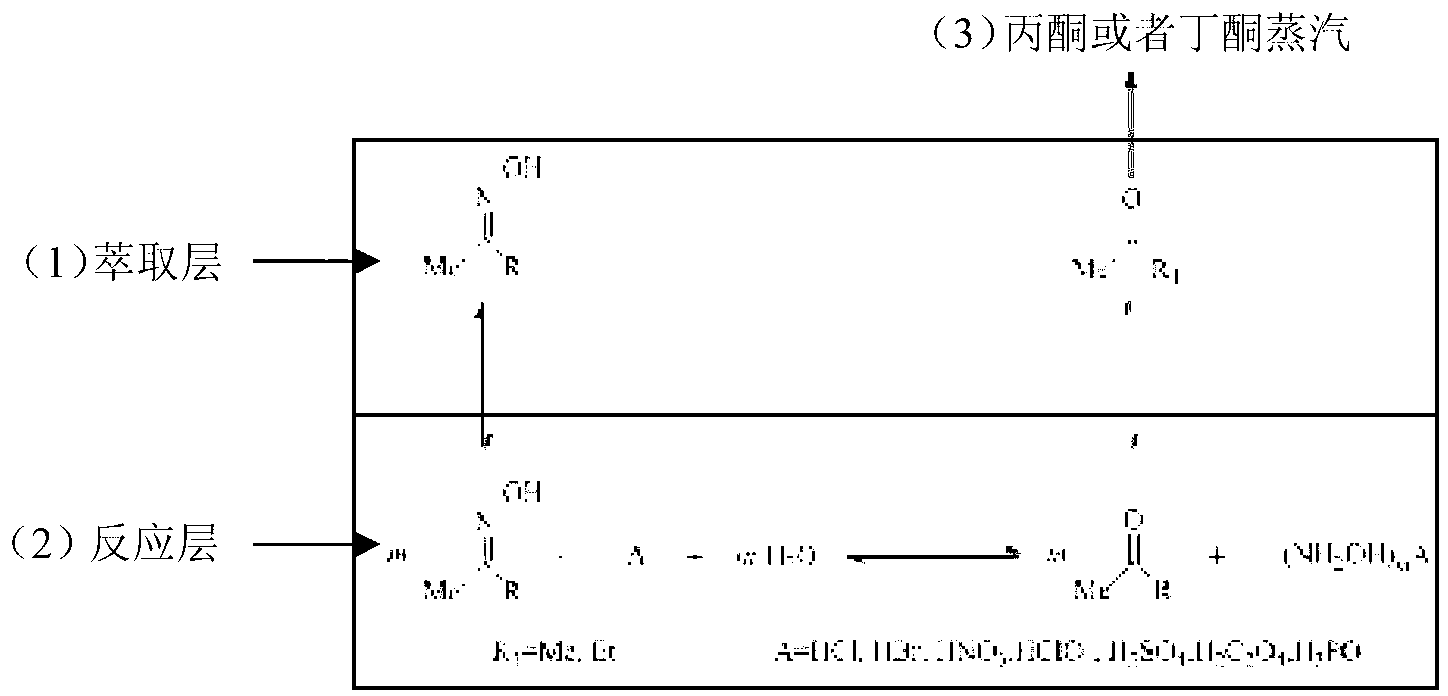

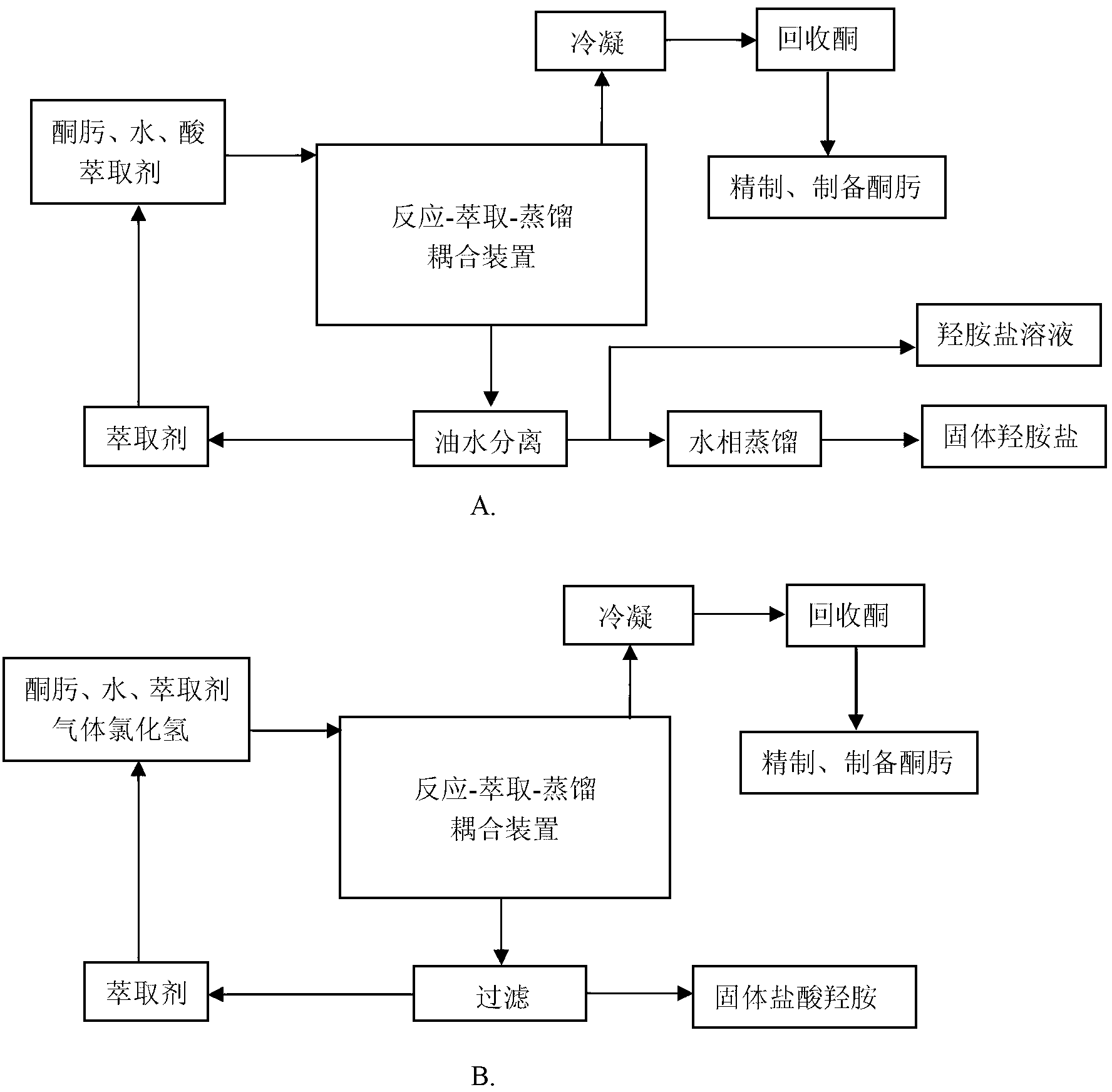

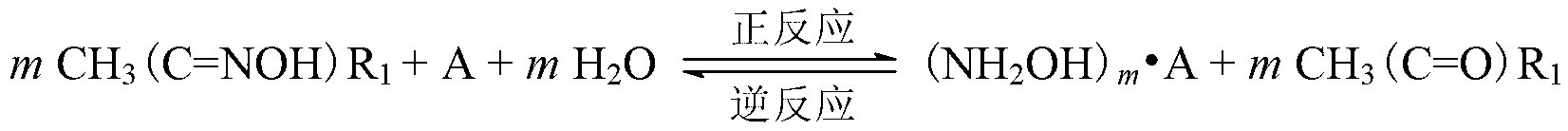

Method used

Image

Examples

Embodiment 1

[0043] (1) Add 7.31kg of acetone oxime and 9.61kg of hydrochloric acid (which contains about 5.95kg of water) into the stirred reactor. The reactants are compatible, and a uniform solution is formed by stirring;

[0044] (2) Add 10L of toluene to the stirred reactor in proportion to make the reaction system an immiscible two-liquid phase system; stir to disperse the extractant phase and the reactant phase and expand the phase boundary between the two phases area;

[0045] (3) Heat the reaction materials to start the reaction, and control the reaction temperature at 50°C. Control the reaction system pressure to 1×10 5 Pa; The acetone generated in the reaction is immediately separated from the aqueous phase into the organic phase, separated by distillation, and recovered by condensation, thus breaking the limitation of the reversible equilibrium reaction and continuously enriching the target product hydroxylamine salt in the aqueous phase. After the reaction, the oil and water...

Embodiment 2

[0047] (1) Add 7.31kg of acetone oxime and 9.61kg of hydrochloric acid (which contains about 5.95kg of water) into the stirred reactor. The reactants are compatible, and a uniform solution is formed by stirring;

[0048] (2) Add 10L of toluene to the stirred reactor in proportion to make the reaction system an immiscible two-liquid phase system; stir to disperse the extractant phase and the reactant phase and expand the phase boundary between the two phases area;

[0049] (3) Heat the reaction materials to start the reaction, and control the reaction temperature at 180°C. Control the reaction system pressure to 1×10 5 Pa; The acetone generated in the reaction is immediately separated from the aqueous phase into the organic phase, separated by distillation, and recovered by condensation, thus breaking the limitation of the reversible equilibrium reaction and continuously enriching the target product hydroxylamine salt in the aqueous phase. After the reaction, the oil and wate...

Embodiment 3

[0051] (1) Add 7.31kg of acetone oxime and 9.61kg of hydrochloric acid (which contains about 5.95kg of water) into the stirred reactor. The reactants are compatible, and a uniform solution is formed by stirring;

[0052] (2) Add 10L of toluene to the stirred reactor in proportion to make the reaction system an immiscible two-liquid phase system; stir to disperse the extractant phase and the reactant phase and expand the phase boundary between the two phases area;

[0053] (3) Heat the reaction materials to start the reaction, and control the reaction temperature at 50°C. Control the reaction system pressure to 1×10 2 Pa; The acetone generated in the reaction is immediately separated from the aqueous phase into the organic phase, separated by distillation, and recovered by condensation, thus breaking the limitation of the reversible equilibrium reaction and continuously enriching the target product hydroxylamine salt in the aqueous phase. After the reaction, the oil and water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com