Process for plating precious metal film on porous ceramic based on magnetron sputtering through vacuum plating

A technology for porous ceramics and precious metals, applied in the field of ceramic vacuum coating process and porous ceramic vacuum coating precious metal film, can solve the problems of thin ceramic palladium film, poor meticulousness and homogeneity, uneven thickness of metal film, etc. Achieve the effect of improving the meticulousness, good homogeneity and uniform thickness of the metal film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

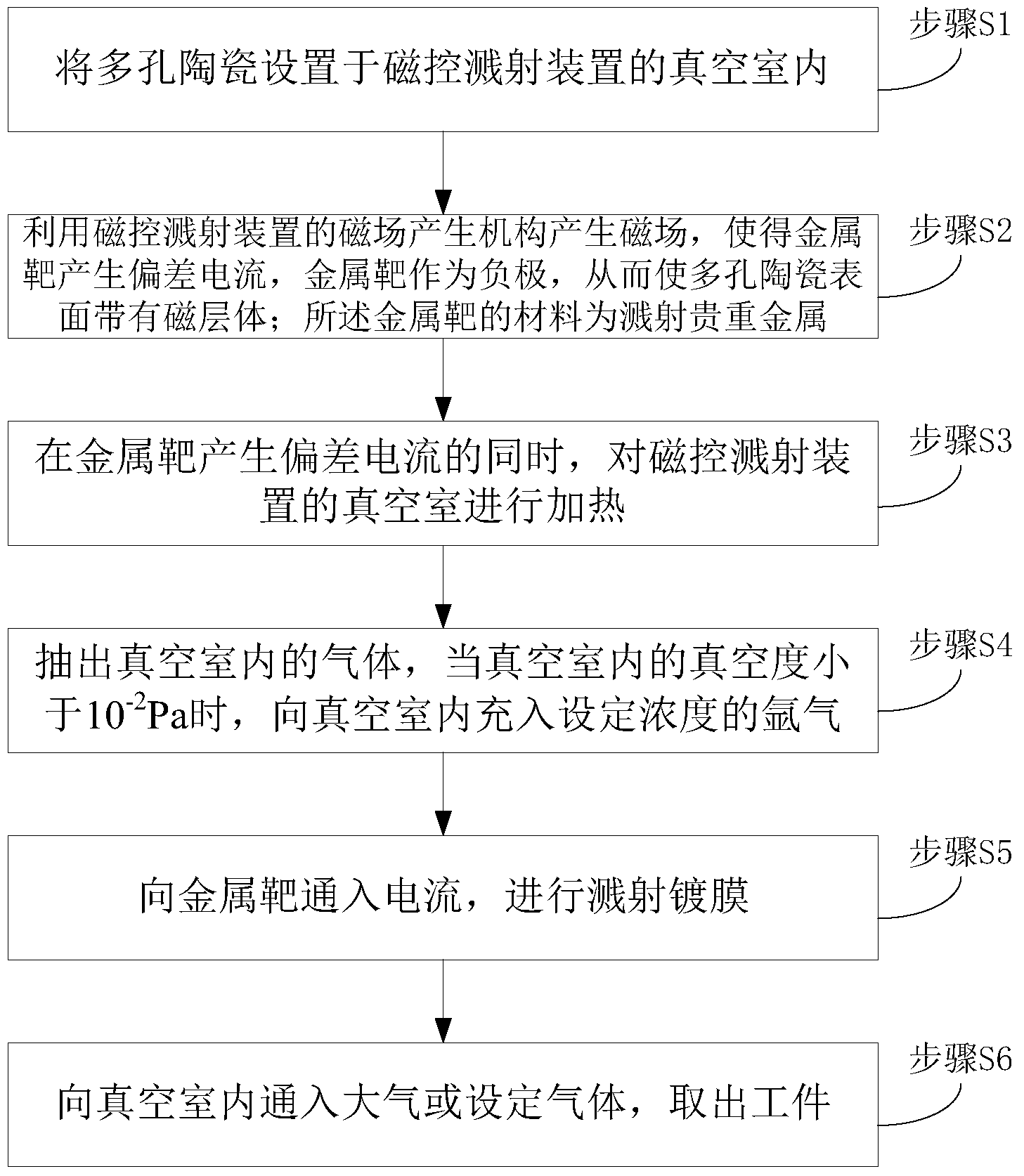

[0048] see figure 1 , the present invention discloses a process for vacuum-plating precious metal films on porous ceramics based on magnetron sputtering, said process comprising the following steps:

[0049] [Step S1] The porous ceramic is placed in a vacuum chamber of a magnetron sputtering device.

[0050] [Step S2] Use the magnetic field generating mechanism of the magnetron sputtering device to generate a magnetic field, so that the metal target generates a bias current, and the metal target is used as a negative pole, so that the surface of the porous ceramic has a magnetic layer; the material of the metal target is expensive sputtering Metal; in the present embodiment, described precious metal is palladium-silver alloy, and mass percentage palladium accounts for 75%~78%, and silver accounts for 22%~25%; Such as, palladium-silver alloy comprises 75% palladium (mass percentage, the same below ), 25% silver, or 78% palladium, 22% silver. In addition, palladium silver allo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com