Urea formaldehyde compound fertilizer containing chelating medium/trace element and preparation method thereof

A technology of medium and trace elements and compound fertilizers, which is applied in fertilizer mixtures, fertilization devices, applications, etc., to achieve the effects of improving utilization rate, using safety and environmental protection, and preventing crop deficiencies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

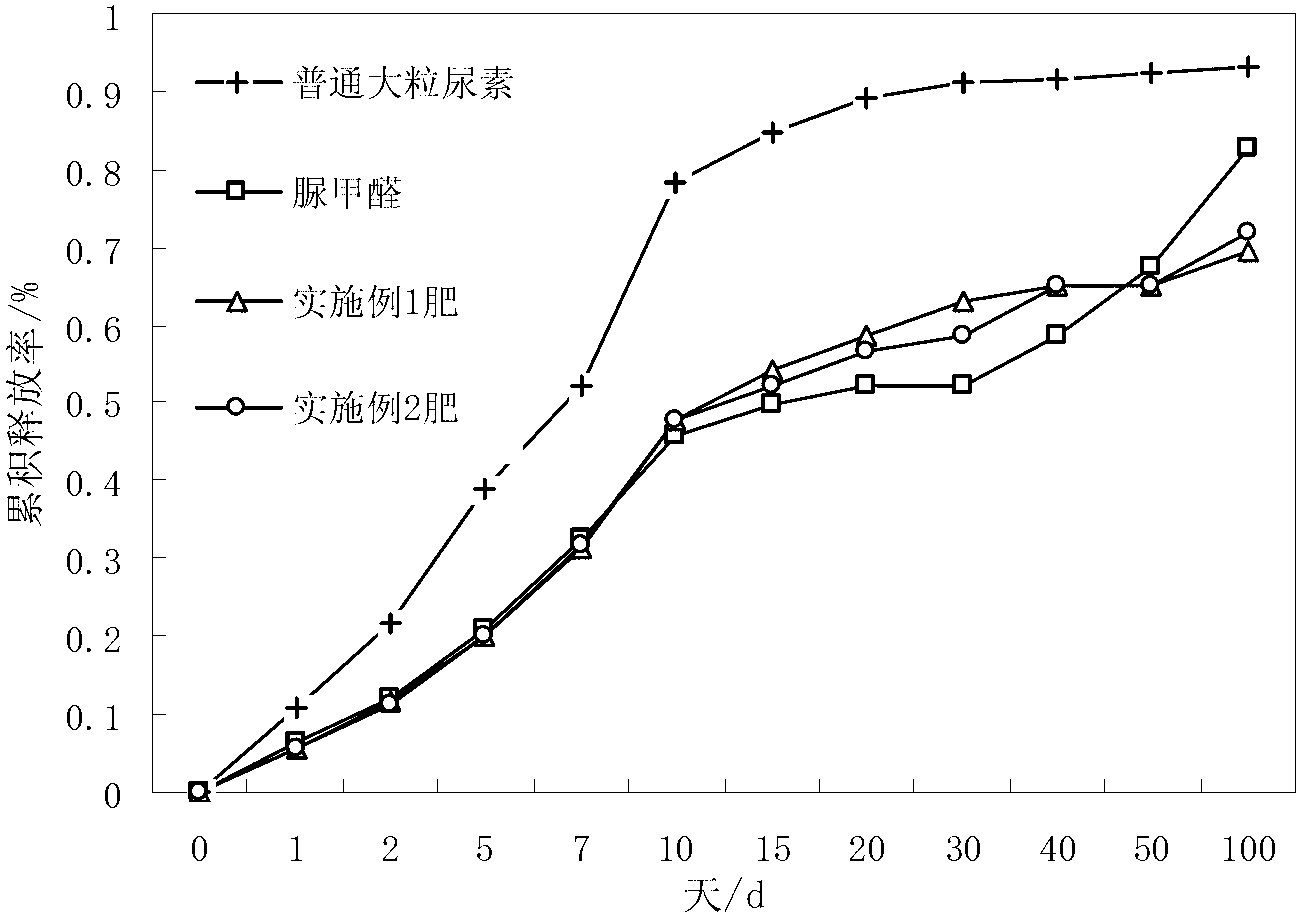

Examples

Embodiment 1

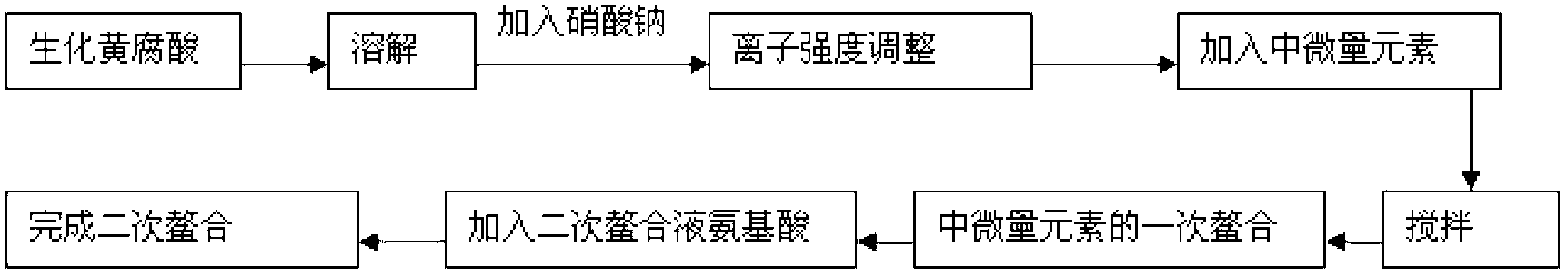

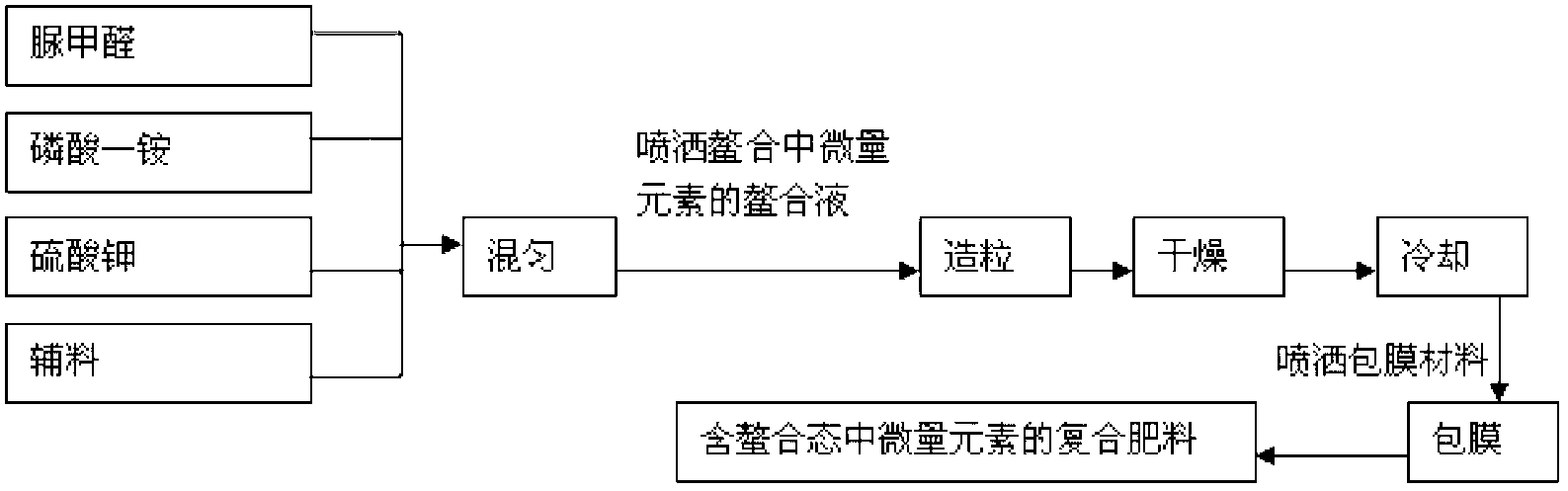

[0030] (1) Preparation of medium and trace element chelating solution:

[0031] Such as figure 1 As shown, select 30kg of high-quality fully water-soluble biochemical fulvic acid (fulvic acid content ≥ 50.0%, pH value 5.5), add 70L of water to dissolve, take 50L of biochemical fulvic acid solution and sodium nitrate with a concentration of 1mol / L After mixing 10L of the solution, add 10kg calcium nitrate, 5kg magnesium sulfate heptahydrate, 1kg borax, 0.7kg zinc sulfate heptahydrate, 0.5kg manganese sulfate, 0.4kg ferrous sulfate, 0.3kg copper sulfate pentahydrate and 0.2kg ammonium molybdate, Maintain a constant temperature of 50°C, stir at a rotational speed of 20r / min, and conduct a chelation reaction of medium and trace elements. The reaction time is controlled at 55h to obtain a chelation solution;

[0032] First, the amino acid solution with a mass percentage of 35% was removed from impurities to ensure that its stability constant was moderate. Take 50L of the above-men...

Embodiment 2

[0039] (1) Preparation of medium and trace element chelating solution:

[0040] Such as figure 1 As shown, select 30kg of high-quality fully water-soluble biochemical fulvic acid (fulvic acid content ≥ 50.0%, pH value 5.5), add 70L of water to dissolve, take 50L of biochemical fulvic acid solution and 10L of nitric acid with a concentration of 1mol / L After mixing the sodium solution, add 9kg calcium nitrate, 4kg magnesium sulfate heptahydrate, 1.3kg borax, 0.5kg zinc sulfate heptahydrate, 0.5kg manganese sulfate, 0.4kg ferrous sulfate, 0.3kg copper sulfate pentahydrate and 0.2kg ammonium molybdate , keep a constant temperature of 50°C, stir at a rotational speed of 20r / min, carry out a chelation reaction of medium and trace elements, and control the reaction time at 55h to obtain a chelation solution;

[0041] First, remove impurities with 35% amino acid solution by mass to ensure that its stability constant is moderate. Take 50L of the above-mentioned primary chelating solut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com