Hydroxyapatite/biodegradable polyester composite material and preparation method thereof

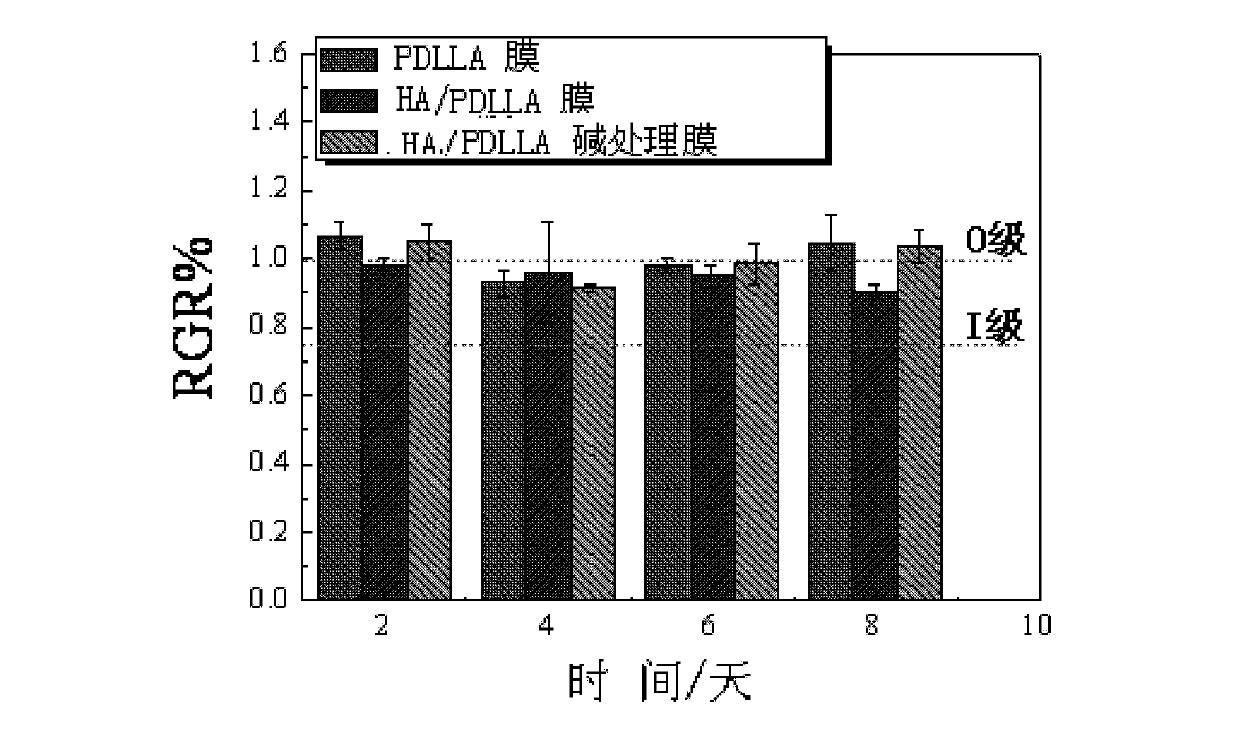

A technology for biodegrading polyester and hydroxyapatite, which is applied in the interdisciplinary field of material science and biomedicine, to achieve excellent biocompatibility, bioactivity and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

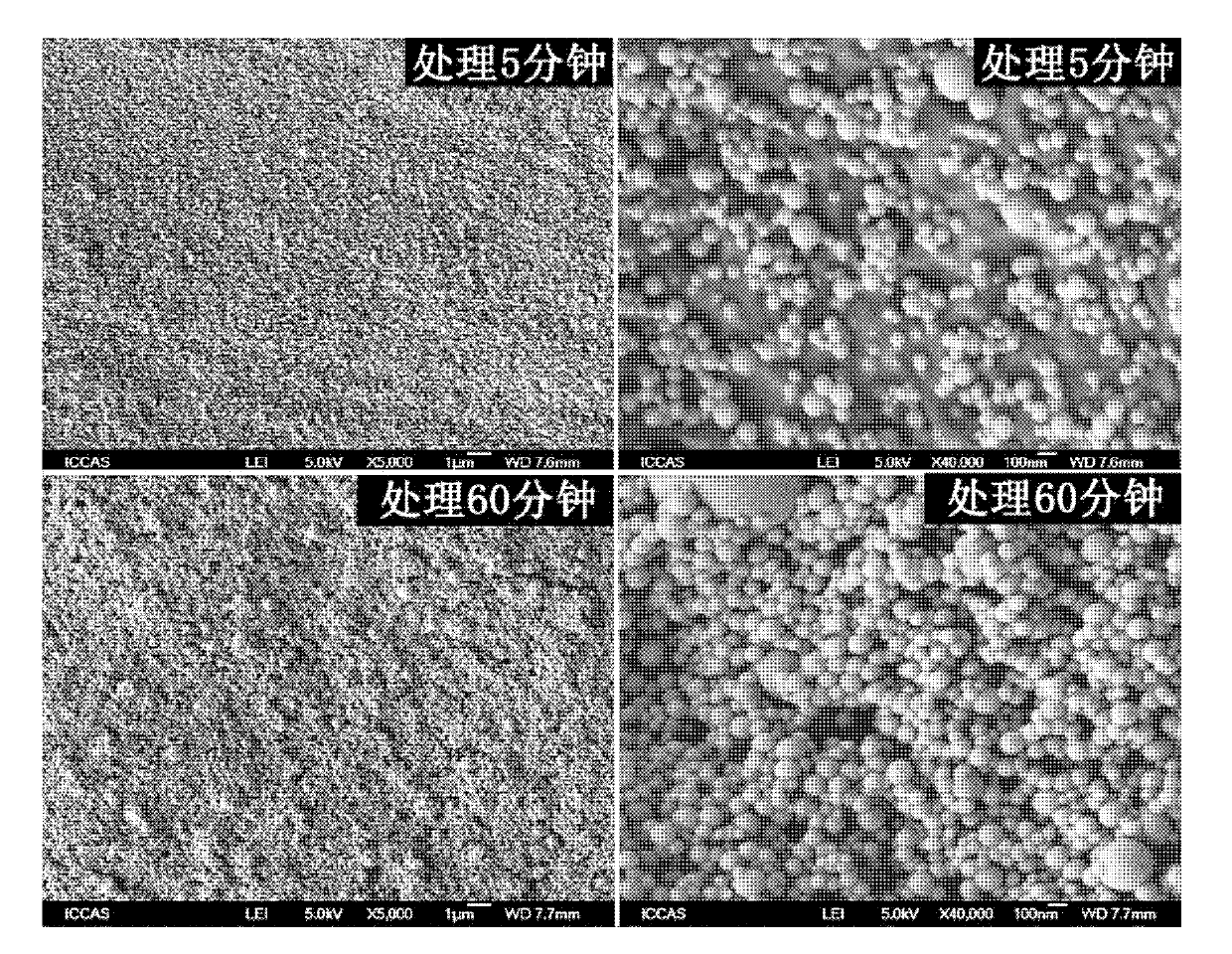

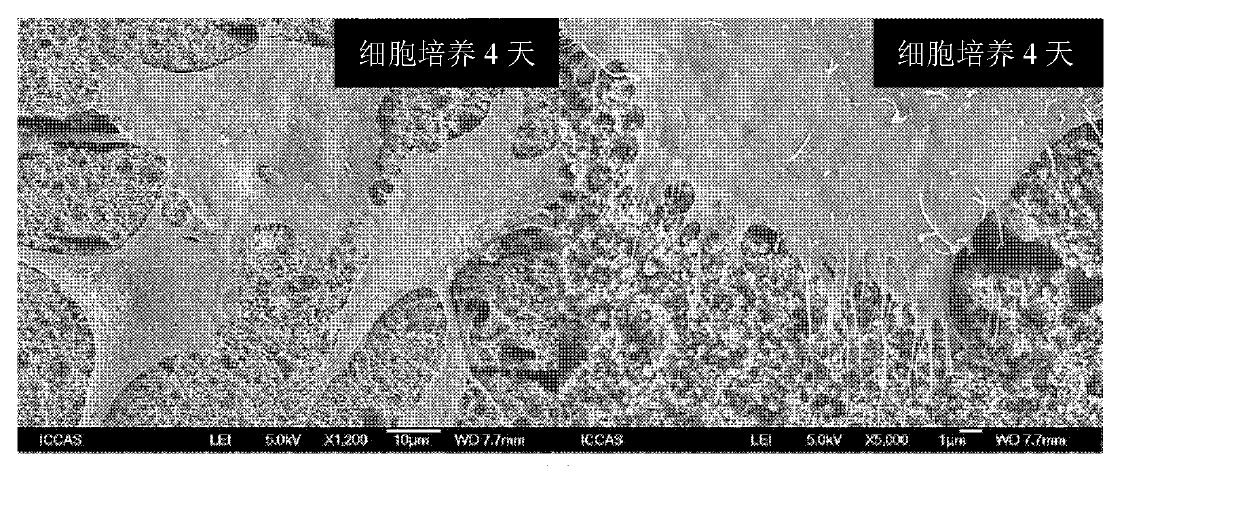

[0032] Embodiment 1, in-situ polymerization prepares PDLLA / HA nanocomposite material

[0033] HA (hydroxyapatite) nanoparticles (with a particle diameter of about 50-200 nm) were dried in a vacuum oven at 100° C. for 2 days before the reaction.

[0034] Under the protection of anhydrous, oxygen and argon, 1 g of dried HA nanoparticles was pre-dispersed in distilled toluene, and then 3 g of D, L-LA monomer and 43 μL of stannous octoate catalyst (molar concentration of 0.982 mol / L), add again distilled toluene 20ml (in this system, HA accounts for D, and the mass percent of L-LA monomer is 33.3%, stannous octoate accounts for D, and the mass percent of L-LA monomer is 0.57%, Magnetic stirring, the reaction temperature is 110°C, and the reaction time is 48 hours; after the reaction, the product is repeatedly dissolved with dichloromethane, and the product is precipitated with ice methanol; after multiple washings, the product is vacuum-dried to obtain the PDLLA / HA nanocomposite ...

Embodiment 2

[0035] Embodiment 2, in-situ polymerization prepares PDLLA / HA nanocomposite material

[0036] HA (hydroxyapatite) nanoparticles (with a particle diameter of about 50-200 nm) were dried in a vacuum oven at 100° C. for 2 days before the reaction.

[0037]Under the protection of anhydrous, oxygen and argon, 1 g of dried HA nanoparticles was pre-dispersed in distilled toluene, and then 3 g of D, L-LA monomer and 108 μL of stannous octoate catalyst (molar concentration of 0.982 mol / L), add again distilled toluene 20ml (in this system, HA accounts for D, and the mass percentage of L-LA monomer is 33.3%, stannous octoate accounts for D, and the mass percentage of L-LA monomer is 1.43%, Magnetic stirring, the reaction temperature is 110°C, and the reaction time is 48 hours; after the reaction, the product is repeatedly dissolved with dichloromethane, and the product is precipitated with ice methanol; after multiple washings, the product is vacuum-dried to obtain the PDLLA / HA nanocomp...

Embodiment 3

[0038] Embodiment 3, in-situ polymerization prepares PDLLA / HA nanocomposite material

[0039] HA (hydroxyapatite) nanoparticles (with a particle diameter of about 50-200 nm) were dried in a vacuum oven at 100° C. for 2 days before the reaction.

[0040] Under anhydrous, oxygen-free and argon protection, 0.1 g of dried HA nanoparticles were pre-dispersed in distilled toluene, and then 10 g of D, L-LA monomer and 144 μL of stannous octoate catalyst (molar concentration of 0.982 mol / L), add again distilled toluene 20ml (in this system, HA accounts for D, and the mass percentage of L-LA monomer is 1%, and stannous octoate accounts for D, and the mass percentage of L-LA monomer is 0.57% , magnetic stirring, the reaction temperature is 110°C, and the reaction time is 48 hours; after the reaction, the product is repeatedly dissolved with dichloromethane, and the product is precipitated with ice methanol; after multiple washings, the product is vacuum-dried to obtain the PDLLA / HA nano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com