Method for preparing polyether lubricating oil by modified plant oil

A technology for modifying vegetable oil and lubricating oil, which is applied in lubricating compositions, petroleum industry, base materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1. Add 20g of dried rapeseed oil into the reactor, then drop 5-6g of potassium hydroxide methanol solution with a mass concentration of 6-8%, control the dropping time at about 20min, and react at 60°C after dropping 1h, wash to neutrality after reaction finishes, obtain transesterification product FME after removing solvent;

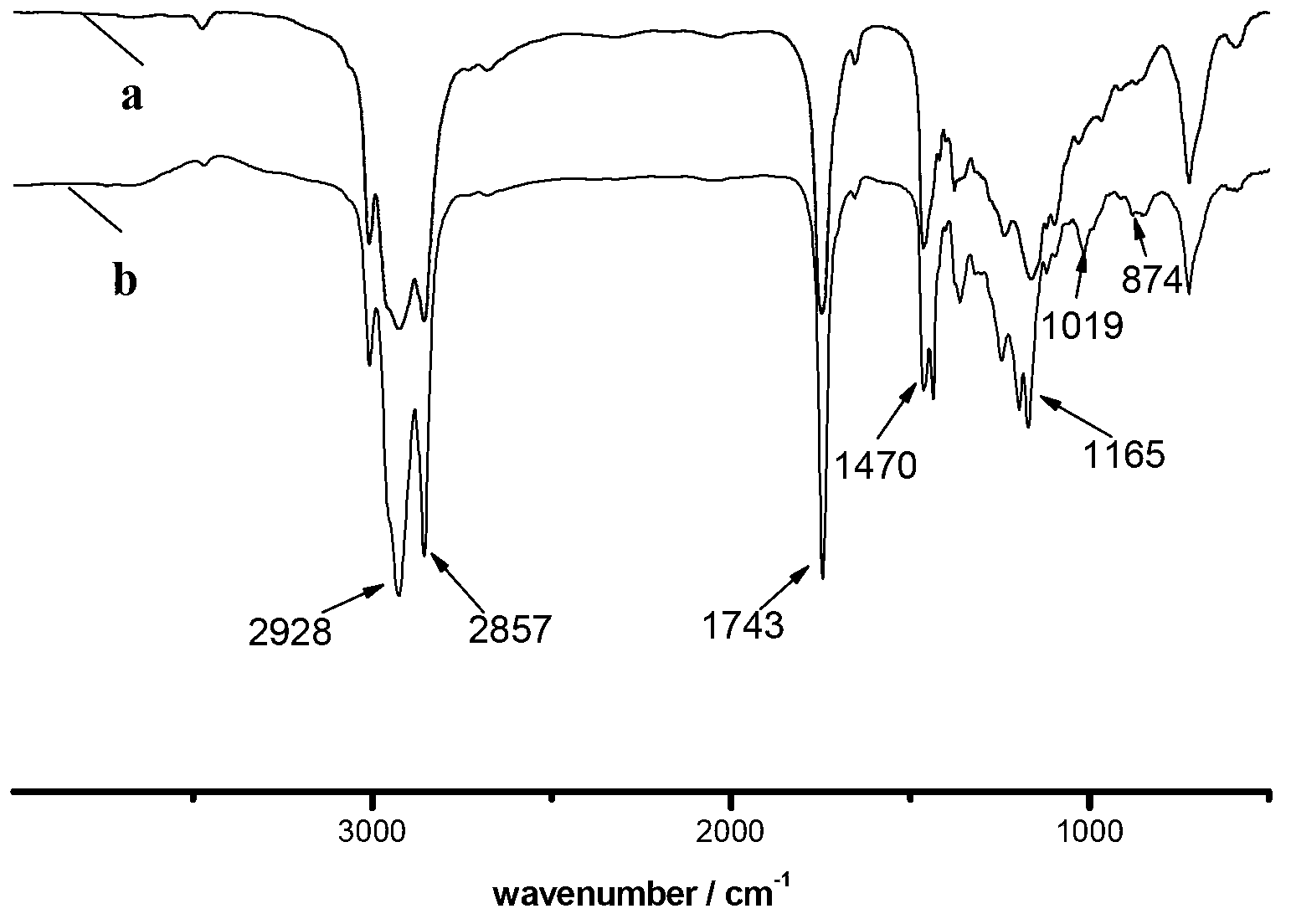

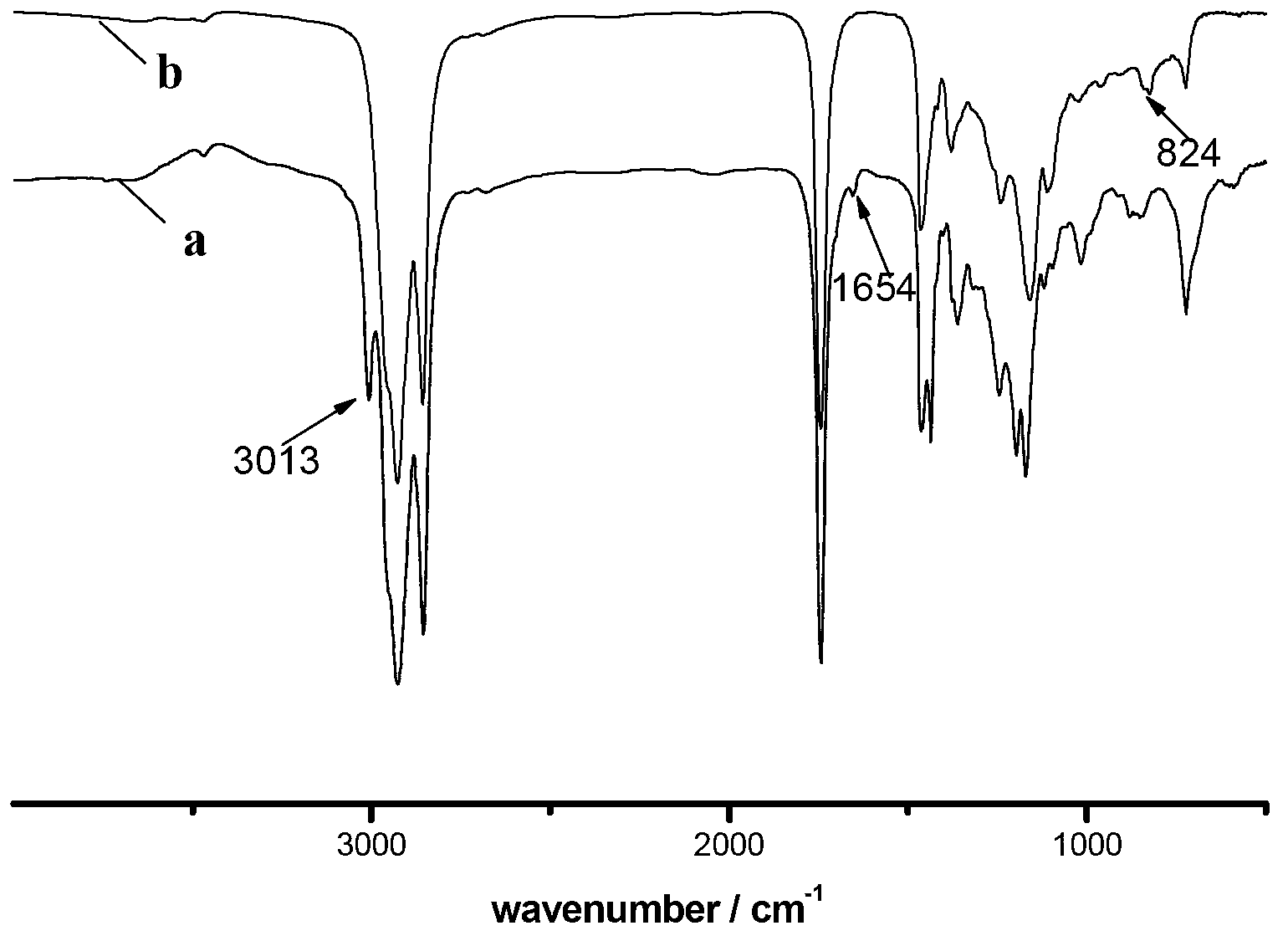

[0030] 2. Add hydrogen peroxide solution dropwise to the mixture of 10g FME, 15ml acetic acid and 0.5g catalyst strong acidic cation exchange resin at 60-70°C, control the dropping time at about 2h, where H 2 o 2 The molar ratio with acetic acid is 1.2:1, keep warm for 4 hours after dripping, wash until neutral after the reaction, and get EFME after removing the solvent;

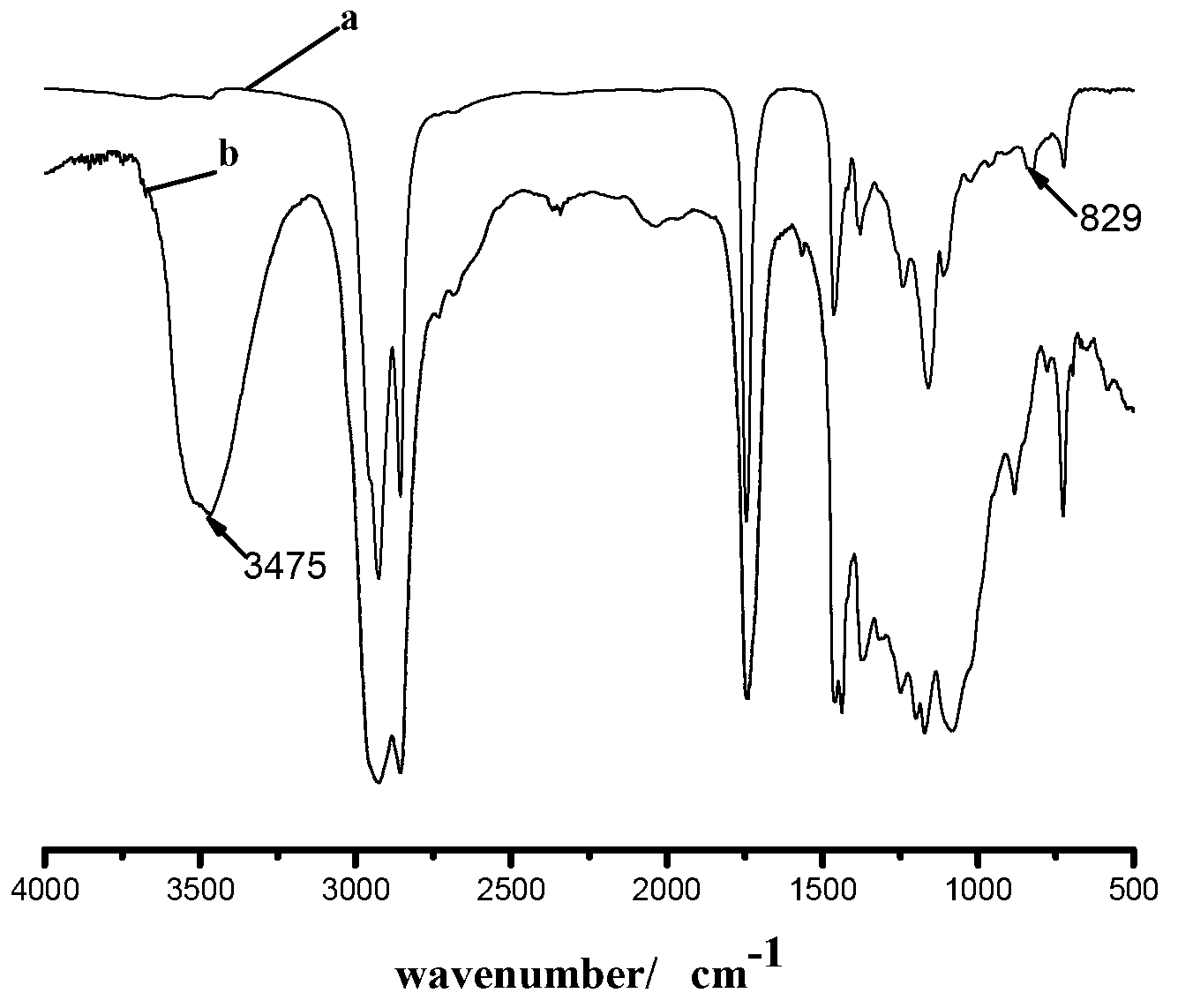

[0031] 3. Add 0.396g of boron trifluoride ether as a catalyst to the reactor equipped with 15g EFME and 300ml of dichloromethane at 0°C under the protection of nitrogen. The adding time is controlled at about 2 minutes, and the reaction is carried out at 0°C after the drop is ...

Embodiment 2

[0035] 1. Add 20g of dried rapeseed oil into the reactor, then drop 5-6g of potassium hydroxide methanol solution with a mass concentration of 6-8%, control the dropping time at about 20min, and react at 60°C after dropping 1h, wash to neutrality after reaction finishes, obtain transesterification product FME after removing solvent;

[0036] 2. Add hydrogen peroxide solution dropwise to the mixture of 10g FME, 15ml acetic acid and 0.5g catalyst strong acidic cation exchange resin at 60-70°C, control the dropping time at about 2h, where H 2 o 2 The molar ratio with acetic acid is 1.2:1, keep warm for 4 hours after dripping, wash until neutral after the reaction, and get EFME after removing the solvent;

[0037] 3. Add 0.396g of boron trifluoride ether as a catalyst to the reactor equipped with 15g EFME and 300ml of dichloromethane at 0°C under the protection of nitrogen. The adding time is controlled at about 2 minutes, and the reaction is carried out at 0°C after the drop is ...

Embodiment 3

[0039] 1. Add 20g of dried rapeseed oil into the reactor, then drop 5-6g of potassium hydroxide methanol solution with a mass concentration of 6-8%, control the dropping time at about 20min, and react at 60°C after dropping 1h, wash to neutrality after reaction finishes, obtain transesterification product FME after removing solvent;

[0040] 2. Add hydrogen peroxide solution dropwise to the mixture of 10g FME, 15ml acetic acid and 0.5g catalyst strong acidic cation exchange resin at 60-70°C, control the dropping time at about 2h, where H 2 o 2 The molar ratio with acetic acid is 1.2:1, keep warm for 4 hours after dripping, wash until neutral after the reaction, and get EFME after removing the solvent;

[0041] 3. Add 0.396g of boron trifluoride ether as a catalyst to the reactor equipped with 15g EFME and 300ml of dichloromethane at 0°C under the protection of nitrogen. The adding time is controlled at about 2 minutes, and the reaction is carried out at 0°C after the drop is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com