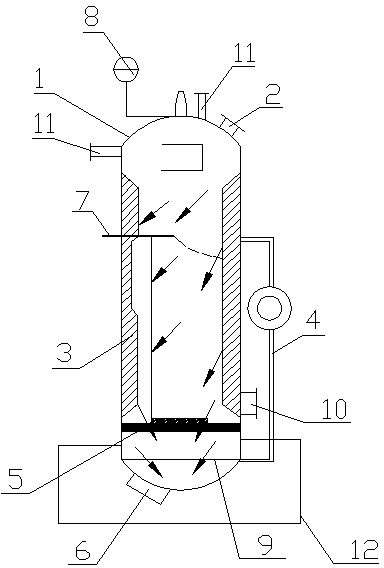

Cotton stalk phloem composite bio-enzyme aqueous solution biological degumming reaction kettle

A composite biological enzyme and biological degumming technology, which is applied in the field of the biological degumming reactor of cotton stalk bast composite biological enzyme aqueous solution, can solve the problems of not realizing industrialization, incompatible with the development of low-carbon economy, and inability to produce textile fibers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

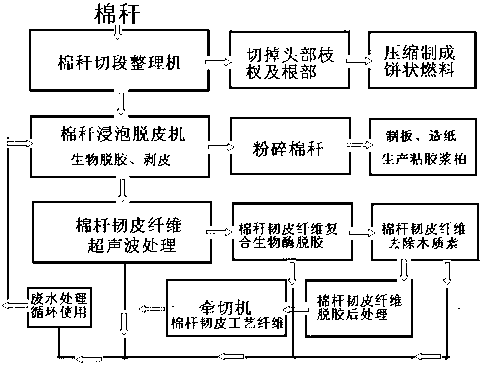

[0020] 1. Primary processing of cotton stalk raw materials

[0021] Cut off the head and tail of the cotton stalk, put the main part in the natural method degumming kettle, and the waste at both ends is made into cake-shaped fuel through a pulverizer and an extruder.

[0022] 2. Cotton stalk bast fiber biological degumming process

[0023] (1) Natural degumming of cotton stalk bast fibers

[0024] Natural degumming is to tie the bast of cotton stalks into small bundles, soak them in a closed degumming kettle with pond water, the bath ratio is 1:30, keep the water temperature at 16-22°C under normal pressure, and after 18-22 days of microbial degumming Oxygen fermentation degumming, using the joint action of various microorganisms in water to produce pectinase and other enzymes, decompose pectin and other macromolecular compounds in cotton stalks into small molecular compounds, and then take out the cotton stalks, which can be peeled with cotton stalks The cotton stalk bark i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com