Electroluminescent diode device

A luminescence and diode technology, which is applied in the field of organic ultraviolet electroluminescent diode devices, can solve the problems such as no light-emitting diode devices have been found, and achieve the effects of reduced starting voltage, improved electro-optical conversion efficiency, and reduced power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

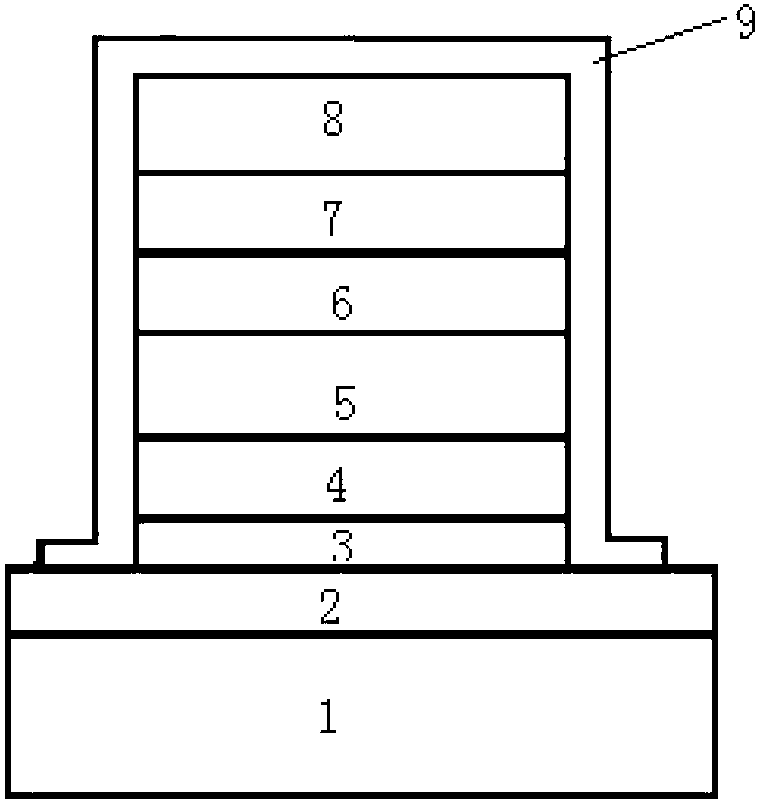

[0044] The structure of the electroluminescent device of the present invention is as figure 1 As shown, from bottom to top includes: It includes:

[0045] A transparent flexible substrate, at least one selected from polymethyl methacrylate, polyethylene adipate or polycarbonate;

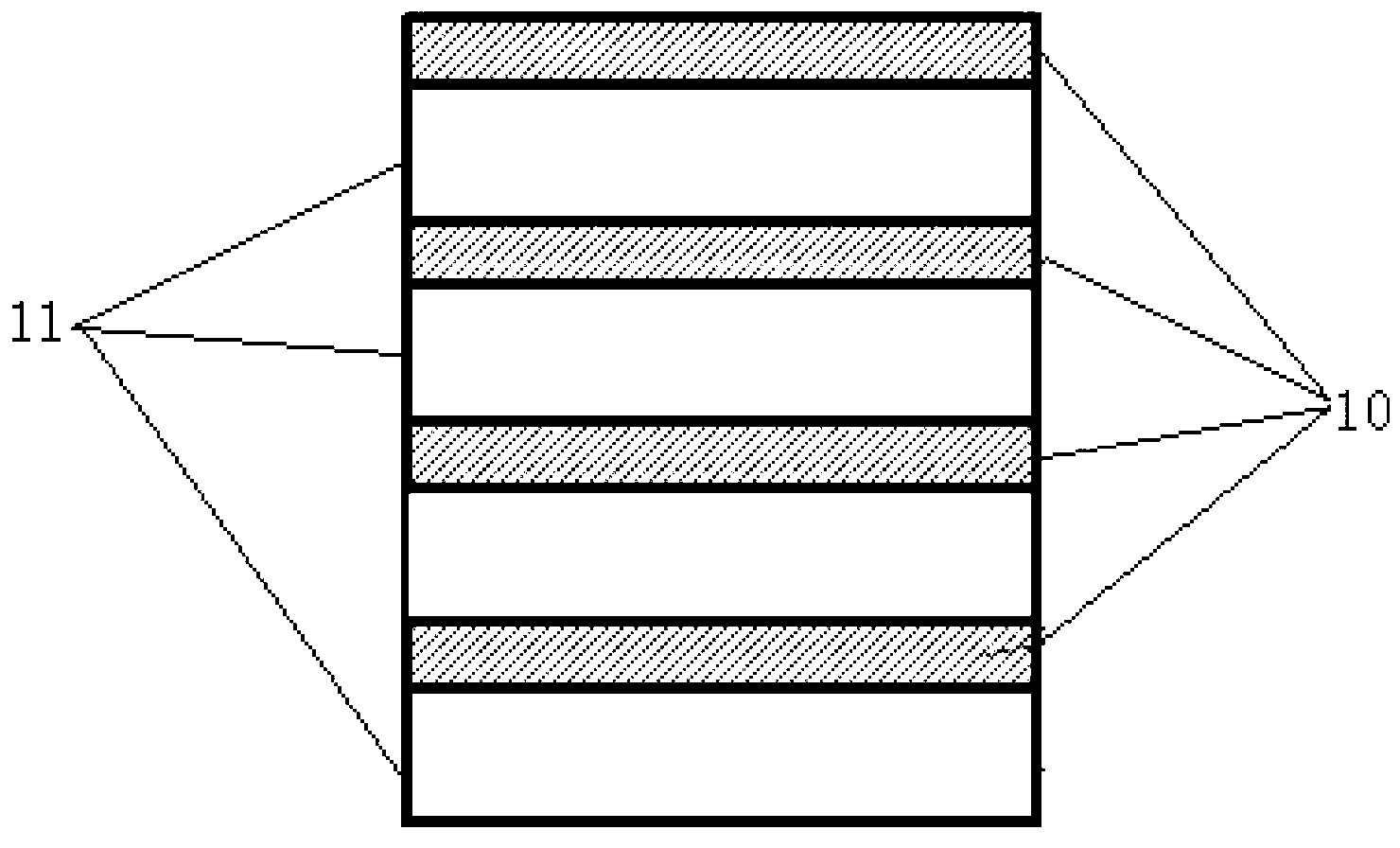

[0046] The first protective layer, which is a barix layer, is composed of alternate laminations of organic polymer materials and inorganic materials; since the materials of the first protective layer need to be able to transmit ultraviolet light, the organic polymer materials can be selectively polymerized Methyl methacrylate, polyethylene adipate or polycarbonate, etc., the inorganic material can be selected from materials with a band gap not smaller than the optical band gap of 3.96eV silicon nitride, such as aluminum nitride, silicon nitride , silicon oxide, etc. Silicon nitride is a commonly used light-transmitting medium for ultraviolet devices;

[0047] an anode, which is an ITO layer;

[0...

Embodiment 2

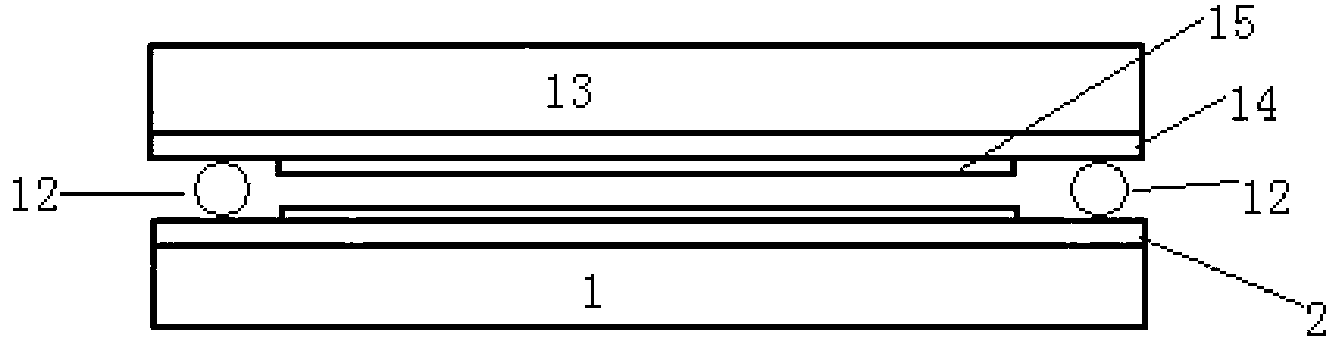

[0061] Such as image 3 As shown, the structure of another electroluminescent diode of the present invention also includes on the basis of the structure disclosed in embodiment 1:

[0062] An encapsulation cover plate, including a flexible cover plate, a third protective layer and a desiccant layer arranged in sequence;

[0063] The structure of the third protective layer is composed of organic polymer materials or alternately stacked organic polymer materials and inorganic materials;

[0064] Wherein, the encapsulation cover plate and the electroluminescent diode are packaged at intervals relative to the outside of the second protective layer in the direction in which the desiccant layer and the electroluminescent diode are arranged in sequence.

[0065] The third protective layer is a Barix layer, and the polymer layer material it includes can be at least one of the organic polymer materials selected from the following substances: parylene, polychlorinated p-xylylene, polye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com