A kind of method and application of making water glass airgel product by freeze-drying method

A technology of freeze-drying and water glass, applied in the direction of silica, silicon oxide, etc., can solve the problems of risk limitation and high cost, and achieve the effects of low time cost, low comprehensive cost and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

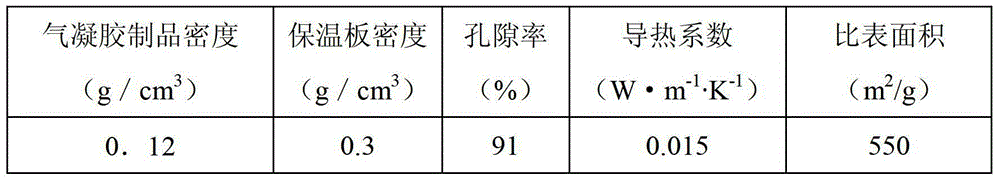

Embodiment 1

[0025] Add 4 times the volume of deionized water to M3.2 industrial water glass at room temperature to dilute, then add 10% hydrochloric acid to adjust the pH to 9, stir evenly, pour into the mold, and place it in the mold A layer of pre-coated reinforced glass fiber wool felt, heated to 60 °C to accelerate the gelation, and stood for 2 hours to form a silica wet gel; a mixed solution of n-hexane and trimethylchlorosilane with a volume ratio of 1:1 Pour into the mold, submerge the wet gel, and let it stand for 24 hours at room temperature for exchange modification; add absolute ethanol to the mold, cover the surface of the wet gel, soak and clean at room temperature for 24 hours, collect the waste liquid after cleaning, and then use distilled water Wash once, and recover the waste liquid; place the product in the mold on the partition in the freeze-drying box, freeze and cool down until the liquid substance in the wet gel product crystallizes into a frozen body; turn on the vac...

Embodiment 2

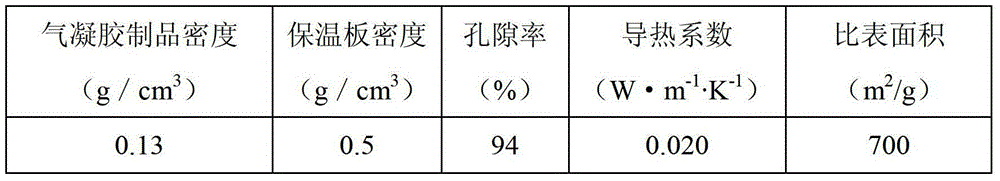

[0029] Add 5 times the volume of deionized water to M3.2 industrial water glass at room temperature to dilute, then add hydrochloric acid with a mass concentration of 10% to adjust the pH value to 10, stir evenly, pour it into the mold, and place it in the mold A layer of pre-coated reinforced glass fiber felt is heated to 60°C to accelerate the gelation, and the silica wet gel is made after standing for 2 hours; a mixed solution of n-hexane and trimethylchlorosilane with a volume ratio of 1:1 Pour into the mold, submerge the wet gel, and stand at room temperature for 36 hours to exchange and modify; add absolute ethanol to the mold, cover the surface of the wet gel, soak and clean at room temperature for 36 hours, collect the waste liquid after cleaning, and then use distilled water Wash 2 times and recover the waste liquid; place the product in the mold on the partition plate of the freeze drying box, freeze and cool down until the liquid substance in the wet gel product crys...

Embodiment 3

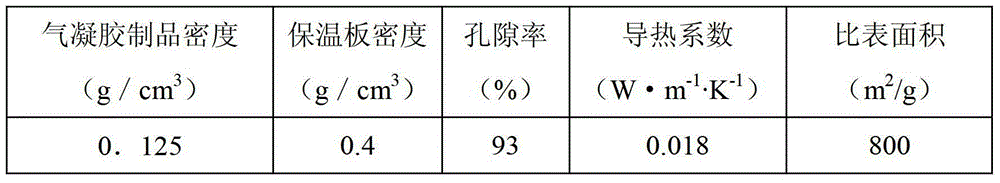

[0033] Add 4.5 times the volume of deionized water to M3.2 industrial water glass at room temperature to dilute, then add hydrochloric acid with a mass concentration of 10% to adjust the pH value to 9-10, stir evenly and pour it into the mold. Place a layer of pre-coated reinforced glass fiber felt inside, heat up to 60°C to accelerate gelation, and let it stand for 2 hours to make silica wet gel; mix n-hexane and trimethylchlorosilane with a volume ratio of 1:1 Pour the mixed solution into the mold, submerge the wet gel, and stand at room temperature for 30 hours to exchange and modify; add absolute ethanol to the mold to cover the surface of the wet gel, soak and wash at room temperature for 30 hours, collect the waste liquid after cleaning, and then Rinse twice with distilled water and recover the waste liquid; place the product in the mold on the partition plate in the freeze-drying box, freeze and cool down until the liquid substance in the wet gel product crystallizes int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com