Preparation method of modified nano calcium borate lubricant additive

A lubricating oil additive, calcium borate technology, applied in the direction of additives, borate, nanotechnology, etc., can solve the problems of complex preparation process of nano-calcium borate, inability to remove sodium ion impurities, large product particle size, etc., to prevent wall sticking , Small particle size and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] a) Weigh 104.1g boric acid (chemical formula: H 3 BO 3 , molecular weight: 62.0) was added to 350ml of water to obtain a boric acid aqueous solution; 15.7g of calcium oxide (chemical formula: CaO, molecular weight: 56.1) was weighed and added to 50ml of water to obtain a lime milk emulsion;

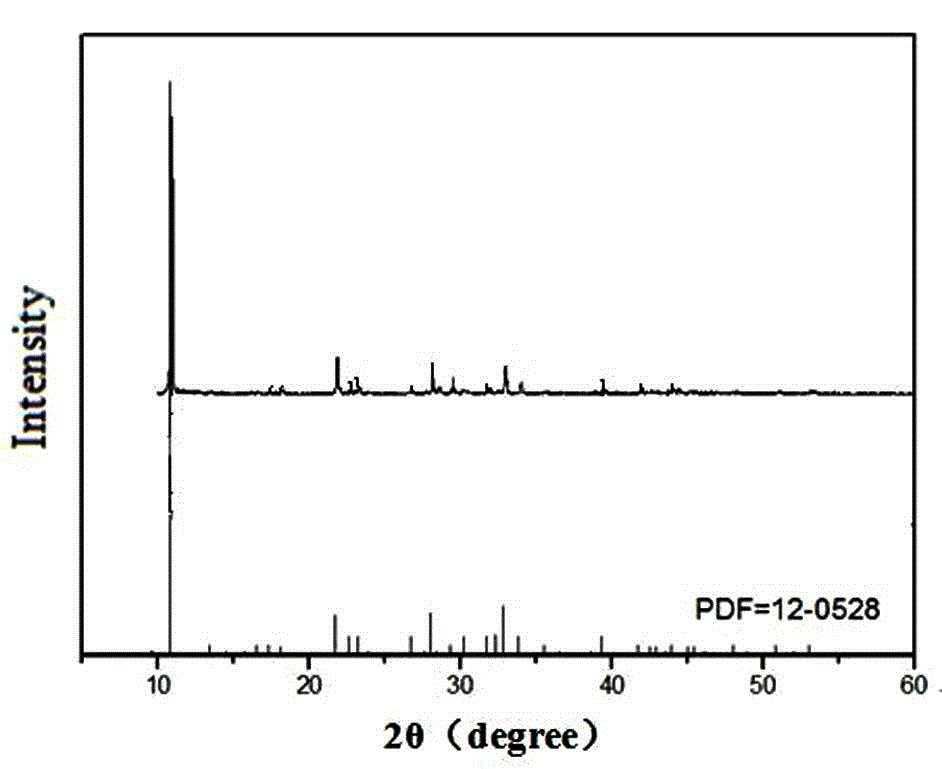

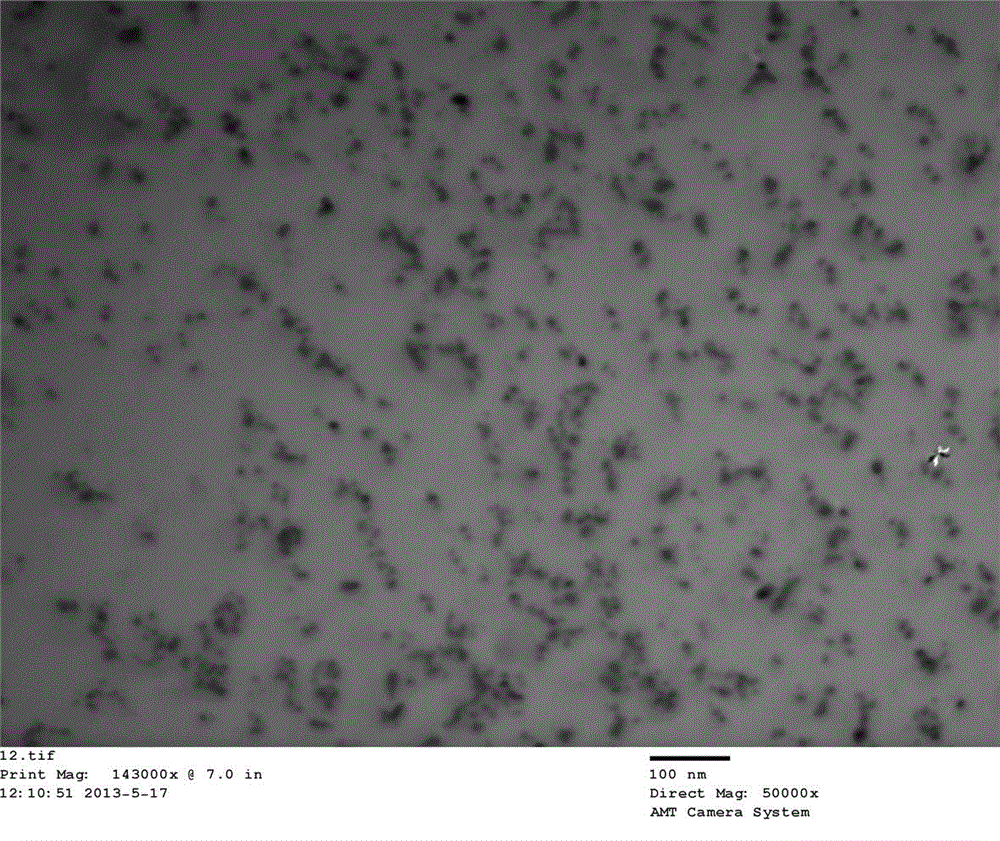

[0020] b) Transfer boric acid aqueous solution and lime milk emulsion into a hydrothermal reaction kettle, stir and mix to make a mixed solution, then add 1.0g cetyltrimethylammonium bromide (CTAB) surfactant and stir to mix , after reacting at 120°C for 20 minutes, suction filtration, drying, and grinding to obtain white CaB with a particle size of 10-15 nanometers 6 o 10 Powder;

[0021] c) Weigh 1.0g nano-CaB 6 o 10 Add the powder to 100ml of water, then add 30ml of oleic acid, stir ultrasonically at a frequency of 25KHz for 10 minutes, then let it stand to separate the oil phase from the water phase, take the upper oil phase, and dry it to obtain oleic acid-modified nano-C...

Embodiment 2

[0025] a) Weigh 104.1g boric acid (chemical formula: H 3 BO 3 , molecular weight: 62.0) was added to 350ml of water to obtain a boric acid aqueous solution; 15.7g of calcium oxide (chemical formula: CaO, molecular weight: 56.1) was weighed and added to 50ml of water to obtain a lime milk emulsion;

[0026] b) Transfer the boric acid aqueous solution and lime milk emulsion into a hydrothermal reaction kettle, stir and mix well, then add 1.5g of cetyltrimethylammonium bromide (CTAB) surfactant and stir to mix. After reacting for 25 minutes, filter with suction, dry and grind to obtain white CaB with a particle size of 10-15 nanometers. 6 o 10 Powder;

[0027] c) Weigh 1.0g nano-CaB 6 o 10 Add the powder to 80ml of water, then add 24ml of oleic acid, stir ultrasonically at 25KHz for 15min, then let it stand to separate the oil phase from the water phase, take the upper oil phase, and dry it to obtain oleic acid-modified nano-CaB 6 o 10 Lubricant additives.

Embodiment 3

[0029] a) Weigh 104.1g boric acid (chemical formula: H 3 BO 3 , molecular weight: 62.0) was added to 350ml of water to obtain a boric acid aqueous solution; 15.7g of calcium oxide (chemical formula: CaO, molecular weight: 56.1) was weighed and added to 50ml of water to obtain a lime milk emulsion;

[0030] b) Transfer boric acid aqueous solution and lime milk emulsion into a hydrothermal reaction kettle, stir and mix well, then add 0.5g of cetyltrimethylammonium bromide (CTAB) surfactant and stir and mix. After reacting for 30 minutes, filter with suction, dry and grind to obtain white CaB with a particle size of 10-15 nanometers. 6 o 10 Powder;

[0031] c) Weigh 1.0g nano-CaB 6 o 10 Add the powder into 150ml of water, then add 45ml of oleic acid, stir ultrasonically at a frequency of 25KHz for 20min, then let it stand to separate the oil phase from the water phase, take the upper oil phase, and dry it to obtain oleic acid-modified nano-CaB 6 o 10 Lubricant additives. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com