EuWo4 (OH) nanoribbon and preparation method of composite material thereof

A technology of nanobelt and tungstic acid, which is applied in the field of preparation of functional nanomaterials, can solve problems such as product impurity, and achieve the effects of good product purity, low production cost, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

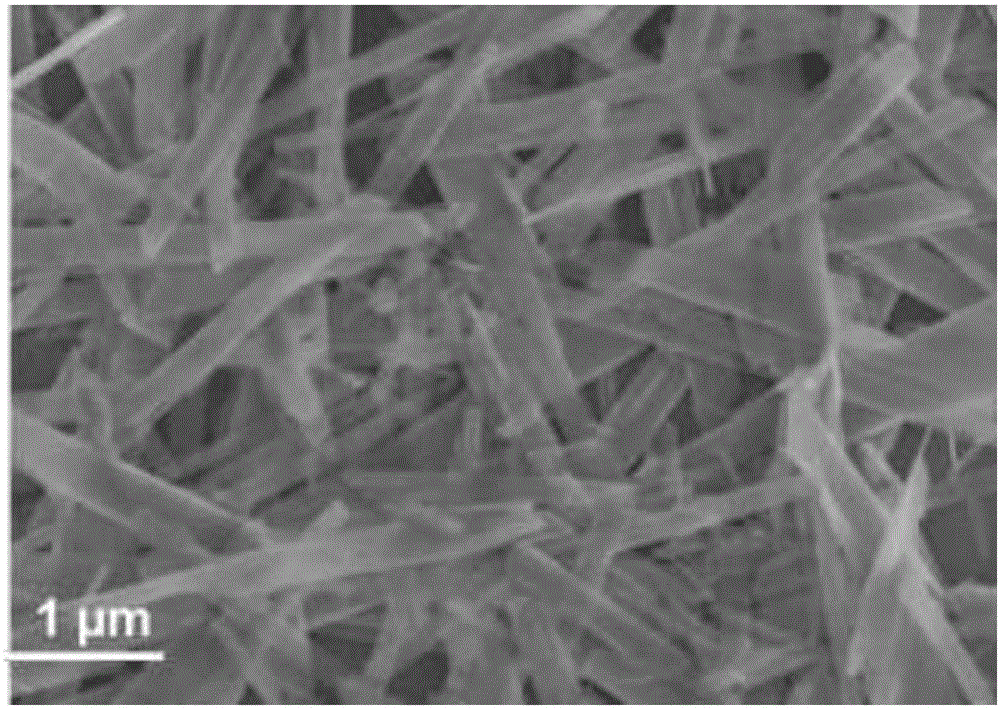

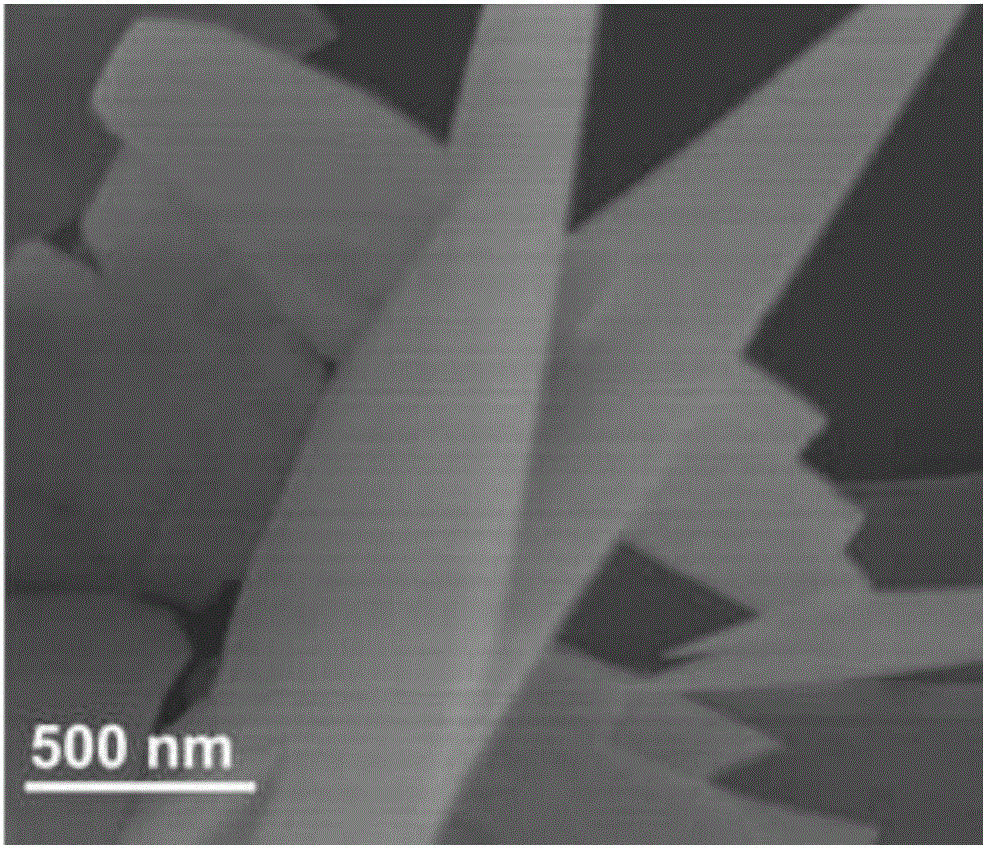

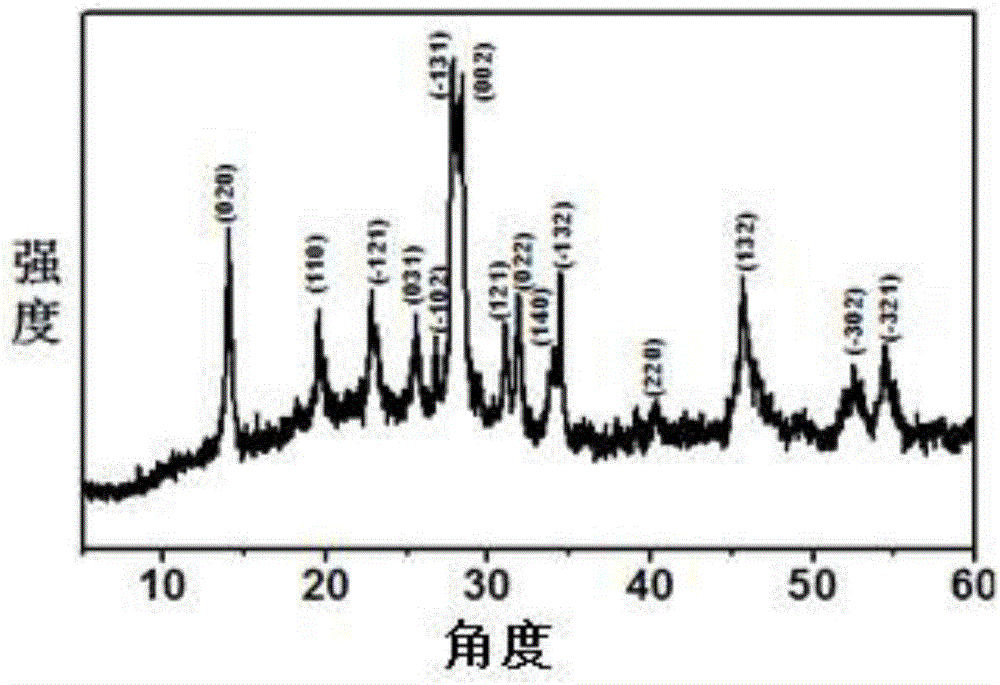

[0026] Mix ammonium tungstate (42mg), thiourea (128mg), europium nitrate (20mg) and 19.44mL of water, heat to dissolve, then add it to a 25mL polytetrafluoroethylene-lined hydrothermal kettle, put it into the To a 220°C oven, react at 220°C for 24 hours. After the reaction was completed, it was left to cool naturally at room temperature. The white solid obtained by the reaction was separated by centrifugation (washed three times with ethanol, washed three times with water), and finally obtained the target product EuWO 4 (OH) nanobelts. figure 1 Shown is the scanning electron micrograph of the product, and it can be seen that the product is a ribbon-shaped material. image 3 Shown is the X-ray single crystal diffraction pattern of the product, the peaks on the spectrum are consistent with the standard card JCPDS card No.23-0428, and there are no miscellaneous peaks, which shows that the purity of basic europium molybdate is very high.

Embodiment 2

[0030] Mix ammonium tungstate (42mg), thiourea (121mg), europium nitrate (16mg) and 19.44mL of water, heat to dissolve, then add it to a 25mL polytetrafluoroethylene-lined hydrothermal kettle, put it into the To a 230°C oven, react at 230°C for 25 hours. After the reaction was completed, it was left to cool naturally at room temperature. The white solid obtained by the reaction was separated by centrifugation (washed three times with ethanol, washed three times with water), and finally obtained the target product EuWO 4 (OH) nanobelts.

Embodiment 3

[0032] Mix ammonium tungstate (42mg), thiourea (130mg), europium nitrate (30mg) and 19.44mL of water, heat to dissolve, then add it to a 25mL polytetrafluoroethylene-lined hydrothermal kettle, put it into the To a 210°C oven, react at 210°C for 23 hours. After the reaction was completed, it was left to cool naturally at room temperature. The white solid obtained by the reaction was separated by centrifugation (washed three times with ethanol, washed three times with water), and finally obtained the target product EuWO 4 (OH) nanobelts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com