Preparation method of hydrogen production composite catalyst

A composite catalyst and sodium hydroxide technology, which is applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve the problems of poor bond breaking ability, high reaction temperature, and easy Carbon deposition and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

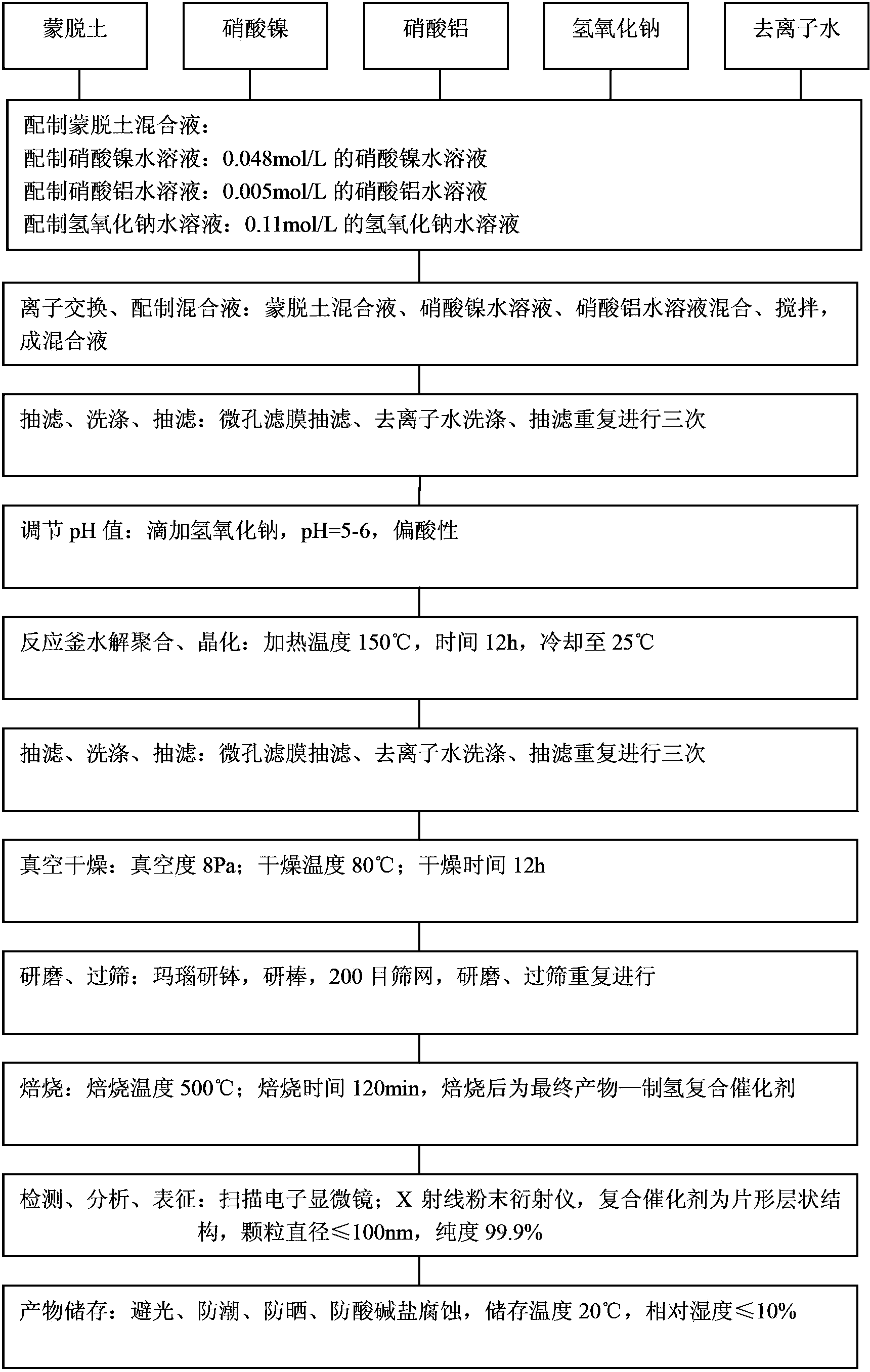

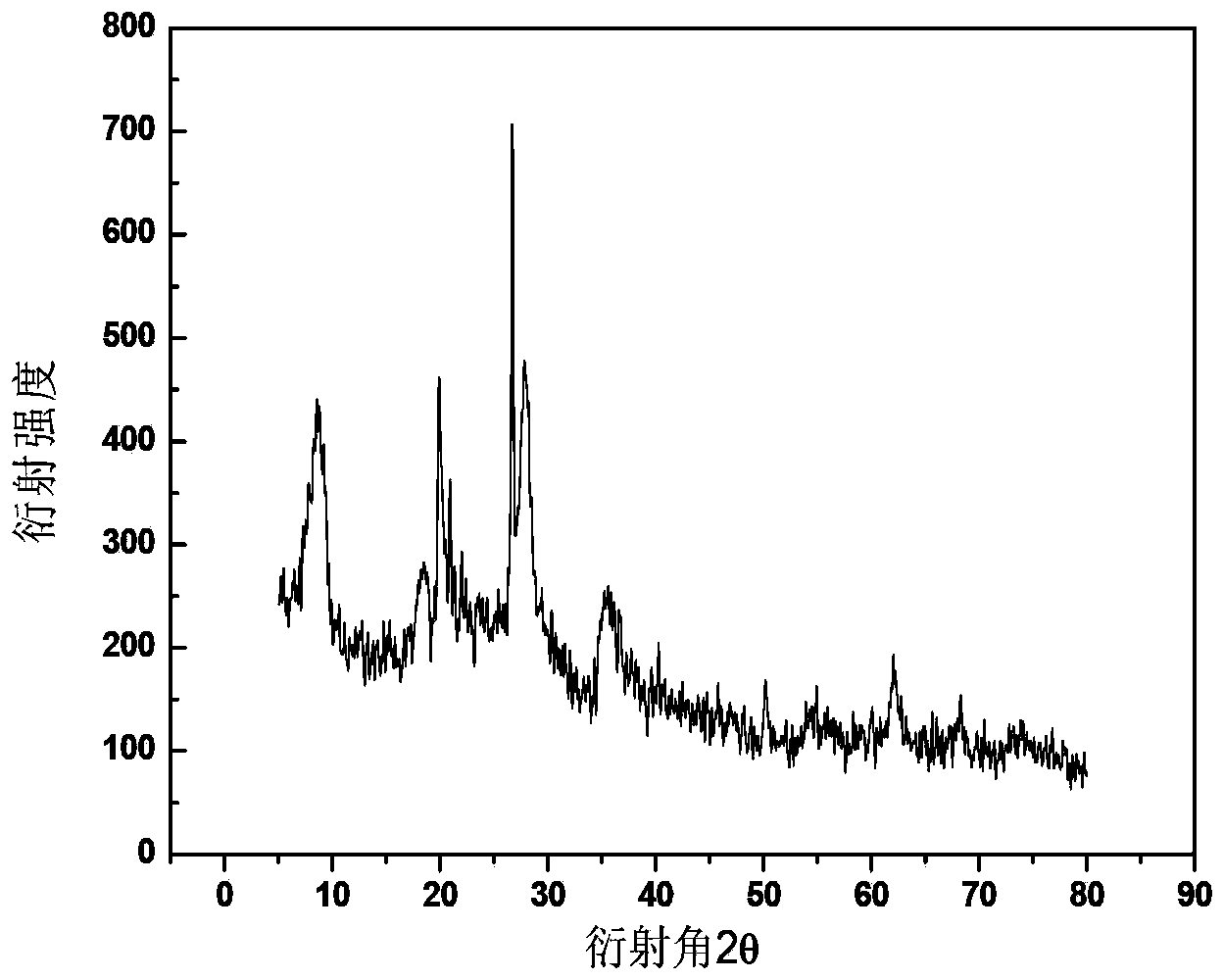

Method used

Image

Examples

Embodiment 1

[0075] The method of using the hydrogen production composite catalyst is as follows:

[0076] (1) Hydrogen production by steam reforming of ethanol is carried out in an atmospheric fixed-bed micro-reactor, and all parts of the atmospheric-pressure fixed-bed micro-reactor are in a quasi-working state;

[0077] (2) Put 3g of composite catalyst in a fixed-bed microreactor at normal pressure;

[0078] (3) Pass the mixed gas of hydrogen and nitrogen into the fixed bed micro-reactor at normal pressure, the volume ratio of hydrogen and nitrogen is 1:1, and perform reduction treatment on the composite catalyst, the reduction temperature is 550°C±5°C, and the reduction time is 2h ;

[0079] (4) After the reduction is completed, stop feeding the mixed gas of hydrogen and nitrogen, and then input nitrogen at a speed of 70cm 3 / min, control the reaction temperature at 500°C±5°C;

[0080] (5) Inject the mixture of ethanol and deionized water into the fixed-bed micro-reactor device at no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com