Preparation method of cheap single-component alkali-activated cement and application method thereof

An alkali-activated cement, single-component technology, applied in the field of new cement materials, can solve the problems of stimulating cement preparation cost competition, etc., and achieve the effect of abundant raw materials, easy access to raw materials, and good early strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

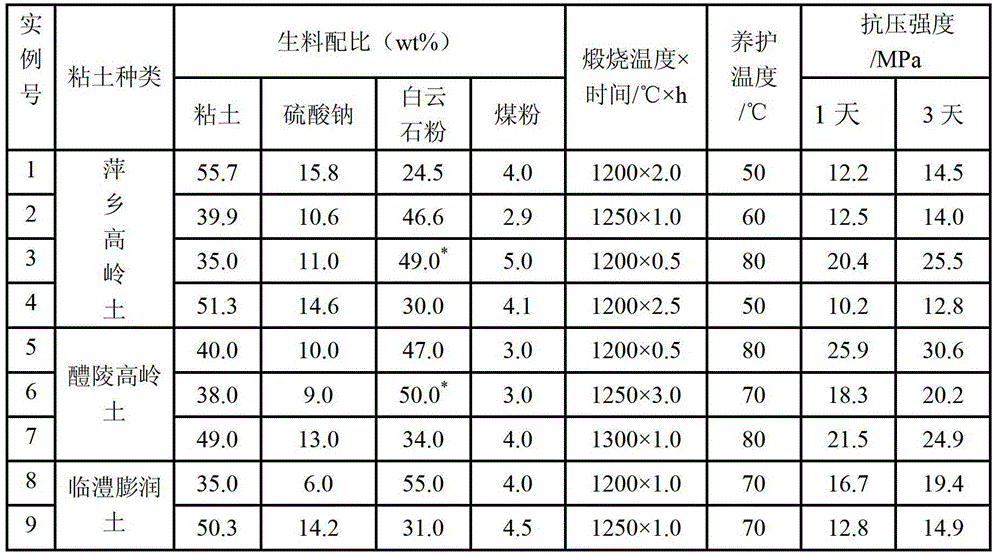

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with specific experimental examples. The equipment used in the embodiments of the present invention is conventional equipment, and the raw materials used are conventional raw materials.

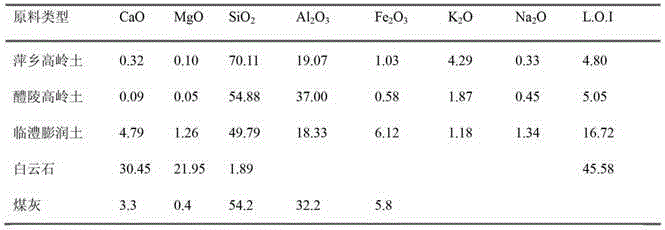

[0024] In the embodiment of the present invention, three kinds of silicon-aluminum raw materials have been prepared, all of which are clays that are easy to grind; the calcium raw materials used have dolomite powder and analytically pure calcium carbonate powder; the cheap alkali metal salts used are Na 2 SO 4 More than 99.9% sodium sulfate; the carbonaceous raw material used is anthracite. The chemical compositions of the raw materials are shown in Table 1. Industrial analysis of anthracite shows that it contains 3.8% moisture, 62.0% fixed carbon, 20.2% ash, and 10.3% volatile matter.

[0025] Table 1 Chemical composition of relevant raw materials Unit: wt%

[0026]

[0027] After drying, each raw ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com