Self-crystallized polymer cement-based waterproof coating, and preparation method thereof

A waterproof coating and polymer technology, applied in the field of waterproof materials, can solve the problems of low strength, poor elongation, and unrepairable cracks in the later stage, and achieve the effects of high elongation, excellent water resistance, and good self-crystallization repair function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

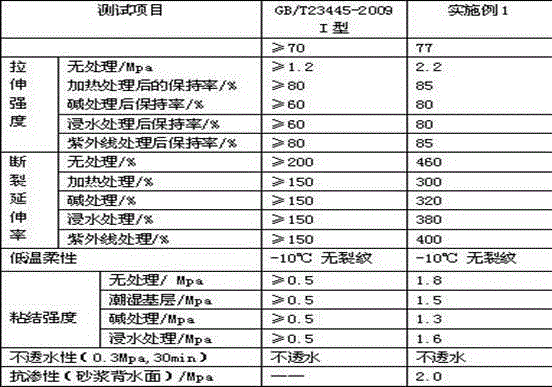

Embodiment 1

[0051] 1) Add 93 parts by weight of vinyl acetate, ethylene and vinyl stearate terpolymer rubber powder dispersion, 2 parts by weight of plasticizer, 3 parts by weight of polyethylhydroxysiloxane into the high-speed disperser, The stirring speed is 1500 rpm, dispersed for 10 minutes, then 2 parts by weight of white oil are added and stirred evenly, and the liquid material is obtained by discharging and packaging;

[0052] 2) Add 30 parts by weight of sulfoaluminate cement, 48.5 parts by weight of 200-mesh quartz sand, 3 parts by weight of gluten, 0.5 parts by weight of borax, and 2 parts by weight of melamine water-reducing agent into the inversion biaxial paddle. Mixer, the blade speed is 200 rpm, the turning speed is 5 rpm, and the mixing is 20 minutes;

[0053] 3) Add 15 parts by weight of wollastonite fibers and 1 part by weight of magnesium aluminum silicate to step 2) and continue stirring for 3 minutes, discharging and packaging to obtain powder;

[0054] 4) When using...

Embodiment 2

[0058] 1) Add 96 parts by weight of vinyl acetate, ethylene and vinyl linoleate terpolymer rubber powder dispersion, 1 part by weight of plasticizer, and 2 parts by weight of sodium ethyl siliconate into the high-speed disperser, and the stirring speed 1000 rpm, disperse for 10 minutes, then add 1 part by weight of polyethylene glycol and stir evenly, discharge and pack to obtain liquid material;

[0059] 2) Add 40 parts by weight of 42.5R Portland cement, 43.5 parts by weight of 200-mesh quartz sand, 4 parts by weight of gluten, 0.5 parts by weight of borax, and 1 part by weight of aliphatic water-reducing agent water-reducing agent. Double shaft paddle mixer, the paddle speed is 300 rpm, the turning speed is 5 rpm, and the mixing is 20 minutes;

[0060] 3) Add 10 parts by weight of sepiolite fibers and 1 part by weight of magnesium lithium silicate to step 2) and continue to stir for 3 minutes, discharging and packaging to obtain powder;

[0061] 4) When using, the liquid m...

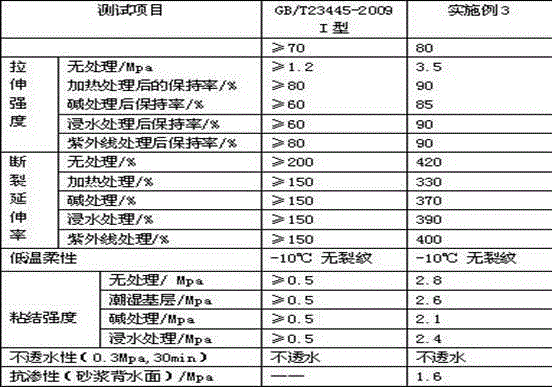

Embodiment 3

[0064] 1) 95 parts by weight of vinyl acetate and ethylene and vinyl stearate terpolymer copolymer powder dispersion, 3 parts by weight of plasticizer, 1 part by weight of sodium methylsiliconate are added to the high-speed disperser, stirring speed 1000 rpm, disperse for 10 minutes, then add 1 part by weight of monoglyceride, stir evenly, discharge and pack to obtain liquid material;

[0065] 2) Add 40 parts by weight of aluminate cement, 44 parts by weight of 200-mesh quartz sand, 3 parts by weight of gluten, 1 part by weight of borax, 1 part by weight of aliphatic water-reducing agent water-reducing agent into the flip-type biaxial Paddle mixer, paddle speed 500 rpm, turning speed 5 rpm, mixing for 10 minutes;

[0066] 3) Add 10 parts by weight of mica fibers and 1 part by weight of magnesium lithium silicate to step 2) and continue to stir for 3 minutes, then discharge and pack to obtain powder;

[0067] 4) When using, the liquid material and the powder material are weigh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com