Preparation method and application of polypyrrole-multiwalled carbon nanotube collaboratively-modified palladium-carried composite electrode

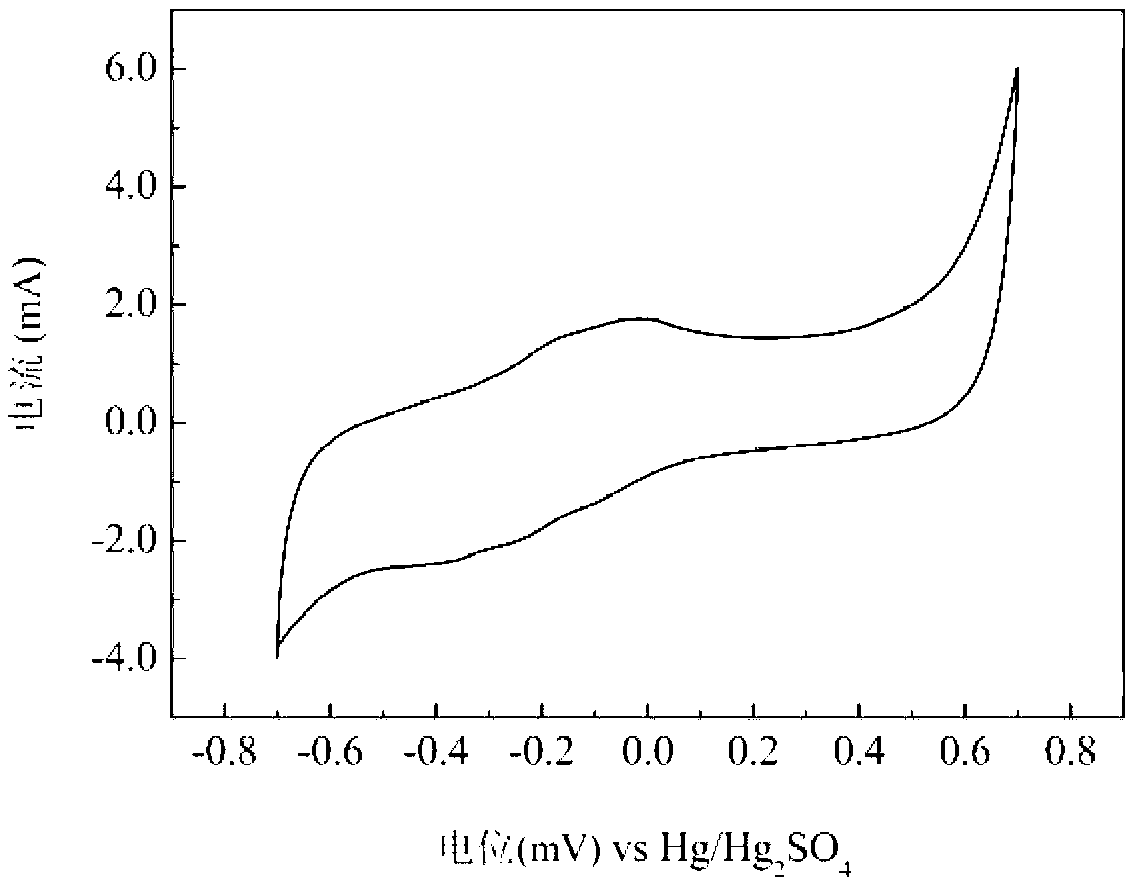

A technology of multi-walled carbon nanotubes and composite electrodes, which is applied in chemical instruments and methods, coating of superimposed layers, electrolytic organic material coating, etc., can solve the problems of low catalytic activity, easy separation of catalyst and matrix, and unstable matrix. , to achieve the effect of high catalytic activity, accelerated dechlorination reaction rate and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

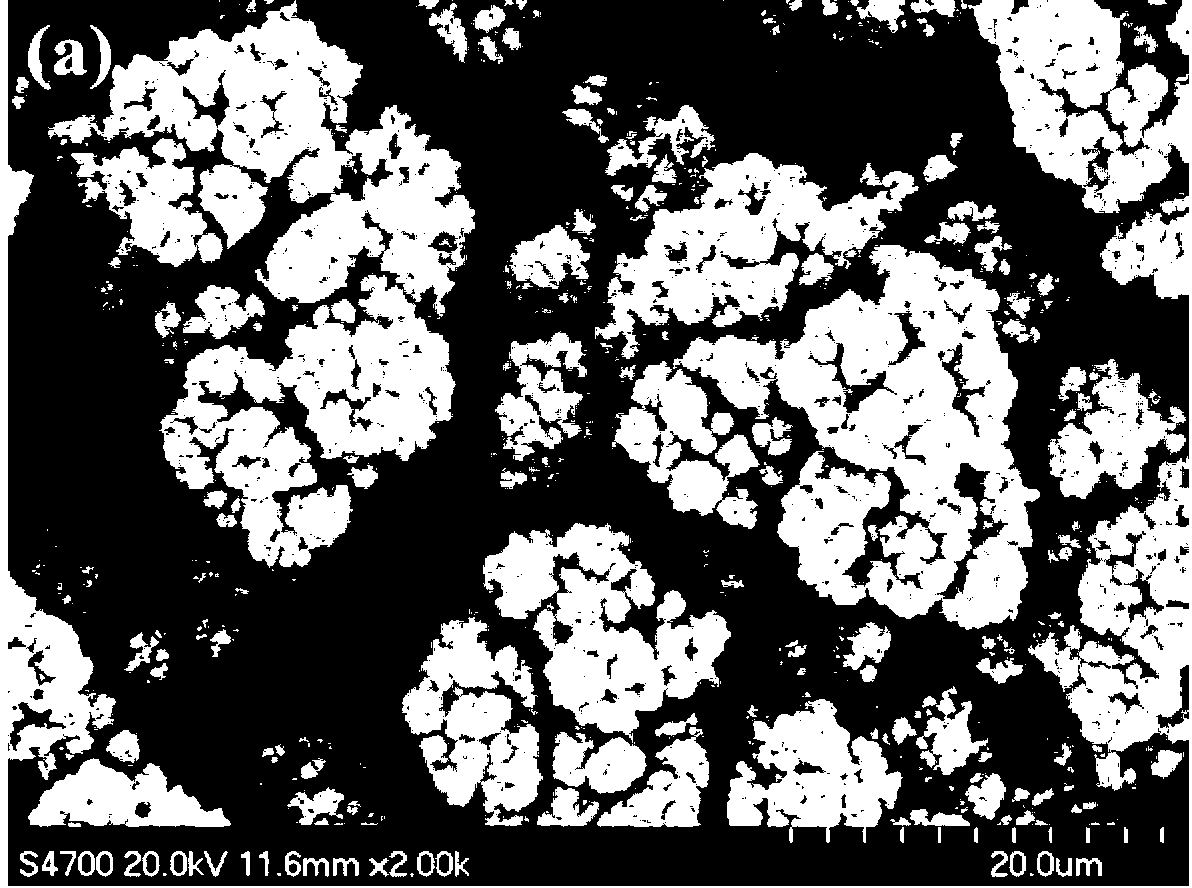

[0032] 1. Palladium chloride (PdCl 2 ) solution preparation: PdCl 2 Dissolve the powder in hydrochloric acid to prepare 33.8mmol / L of PdCl 2 solution.

[0033] 2. Pretreatment of titanium (Ti) mesh substrate: Soak Ti mesh in 0.3mol / L sodium carbonate solution for 30 minutes, boiled 0.1mol / L oxalic acid solution for 30 minutes, rinse with double distilled water until neutral and set aside.

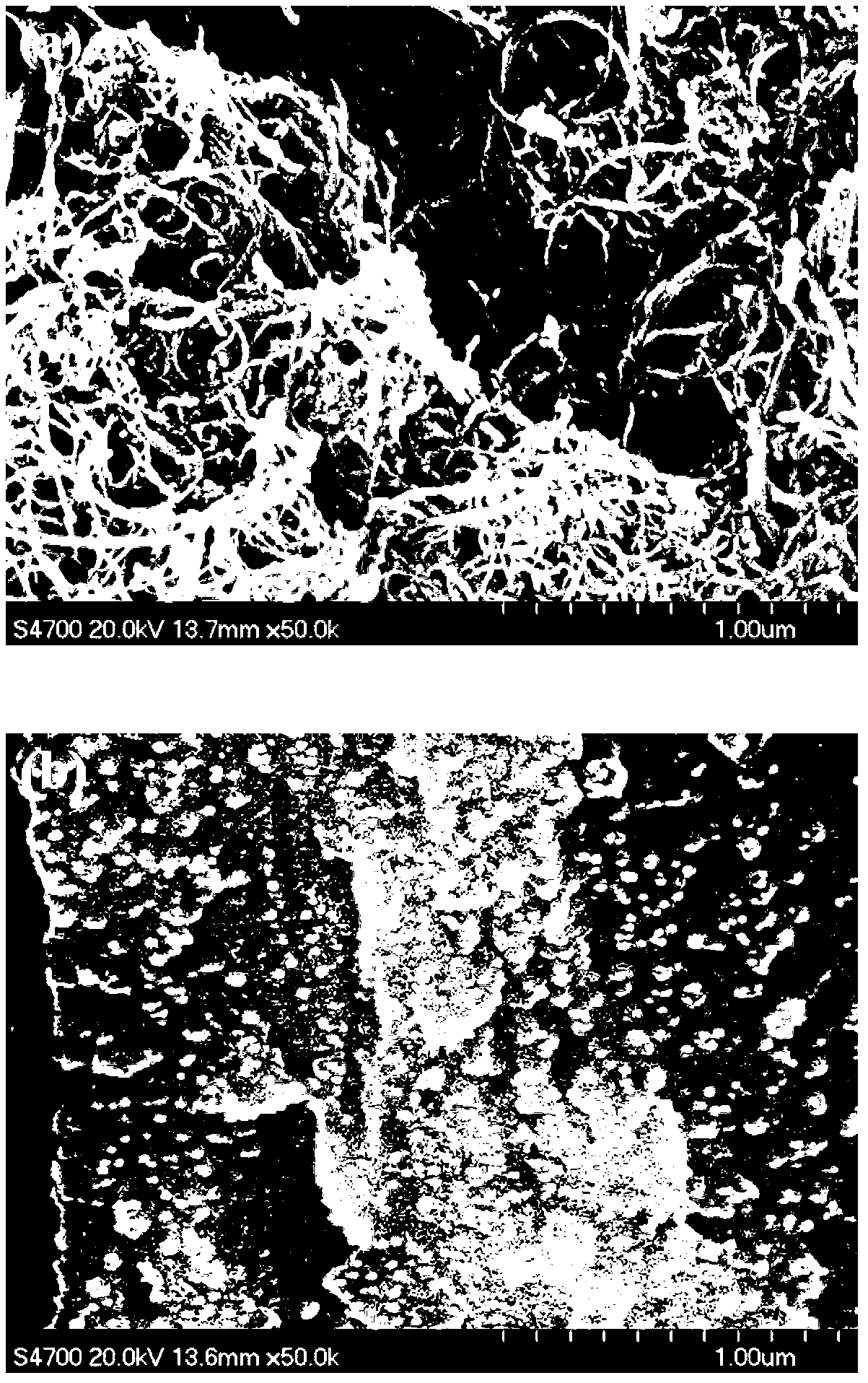

[0034] 3. Pretreatment of MWCNTs: Take multi-walled carbon nanotubes (MWCNTs) with a diameter of 15-20nm and put them into a sufficient amount of concentrated nitric acid. After ultrasonication for 4 hours, dilute with double distilled water, rinse and filter repeatedly until neutral spare.

[0035] 4. Add 5 mg of MWCNTs pretreated in step 3 into 10 mL of acetone, and sonicate for 30 minutes to form a suspension of MWCNTs.

[0036] 5. Take the pretreated Ti mesh with a clean surface, put it into the MWCNTs suspension obtained in step 3 and soak for 20 minutes, then pull out the suspension...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com