Solid oxide fuel cell anode material and preparation method and application thereof

A solid oxide and fuel cell technology, applied in the energy field, can solve the problems of violent powder expansion, waste of raw materials, and collection difficulties, and achieve the effects of enhancing electrical conductivity, easy operation, and avoiding collection difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

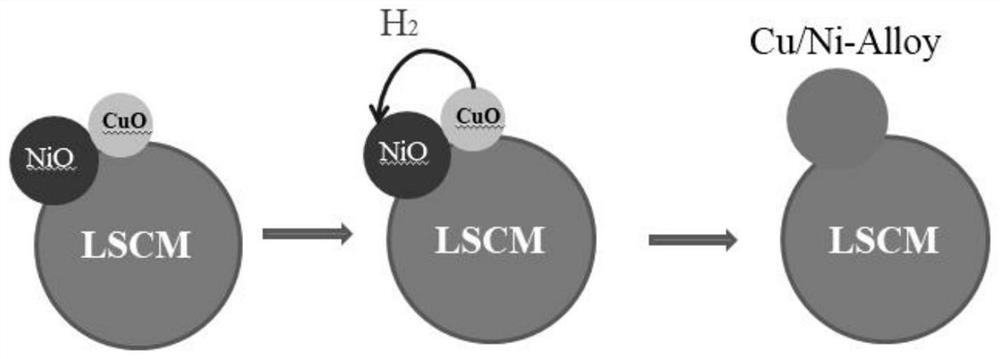

[0039] This embodiment provides a method for preparing an anode material for a solid oxide fuel cell, comprising the following steps:

[0040] Sr(NO 3 ) 2 ·6H 2 O, La(NO 3 ) 3 ·6H 2 O, Cr(NO 3 ) 2·6H 2 O and Mn(NO 3 ) 2 , put it in a beaker, add deionized water and stir to dissolve until the solution is mixed and homogeneous; then weigh the corresponding mass of citric acid according to 1.5 times the molar weight of the total elements of lanthanum, strontium, chromium and manganese, and then stir in a magnetic stirrer Stir evenly for 2 hours, then place the beaker on an electric furnace to heat and boil until spontaneous combustion occurs, collect the reacted product and place it in a tube furnace, and calcinate it in an air atmosphere at 1350°C for 4 hours to obtain LSCM powder La x Sr 1-x Cr y mn 1-y o 3-δ In x=0.7, y=0.5, that is, the structural formula of the LSCM powder of this embodiment is La 0.7 Sr 0.3 Cr 0.5 mn 0.5 o 3-δ .

[0041] Weigh 6g of calc...

Embodiment 2

[0044] This embodiment provides a method for preparing an anode material for a solid oxide fuel cell, comprising the following steps:

[0045] Sr(NO 3 ) 2 ·6H 2 O, La(NO 3 ) 3 ·6H 2 O, Cr(NO 3 ) 2 ·6H 2 O and Mn(NO 3 ) 2 , put it in a beaker, add deionized water and stir to dissolve until the solution is mixed and homogeneous; then weigh the corresponding mass of citric acid according to 1.5 times the total element molar weight of lanthanum, strontium, chromium and manganese, and then stir it under magnetic force Stir in a container for 2 hours to stir evenly, then place the beaker on an electric furnace and heat to boil until spontaneous combustion occurs, collect the reacted product and place it in a tube furnace, and calcinate it in an air atmosphere at 1350°C for 4 hours to obtain the structural formula for la 0.7 Sr 0.3 Cr 0.5 mn 0.5 o 3-δ LSCM powder.

[0046] Weigh 6g of the calcined product LSCM powder in a beaker, add 3g of nickel nitrate, 1g of copper...

Embodiment 3

[0049] This embodiment provides a method for preparing an anode material for a solid oxide fuel cell, comprising the following steps:

[0050] Sr(NO 3 ) 2 ·6H 2 O, La(NO 3 ) 3 ·6H 2 O, Cr(NO 3 ) 2 ·6H 2 O and Mn(NO 3 ) 2 , put it in a beaker, add deionized water and stir to dissolve until the solution is mixed and homogeneous; then weigh the corresponding mass of citric acid according to 1.5 times the total element molar weight of lanthanum, strontium, chromium and manganese, and then stir it under magnetic force Stir in a container for 2 hours to stir evenly, then place the beaker on an electric furnace and heat to boil until spontaneous combustion occurs, collect the reacted product and place it in a tube furnace, and calcinate it in an air atmosphere at 1350°C for 4 hours to obtain LSCM powder.

[0051] Weigh 6g of the calcined product LSCM powder in a beaker, add 2g of nickel nitrate, 2g of copper nitrate and deionized water, place the beaker containing the mixe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com