Composite electrode material containing reactive plasma spraying nanometer TiN middle layer and preparation method thereof

A composite electrode and intermediate layer technology, applied in the field of electrochemistry, can solve the problems of difficulty in preparing a thick intermediate layer film, unsuitable for large-area electrodes, complicated processes, etc., and achieve the effects of long service life, improved oxygen evolution potential, and good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

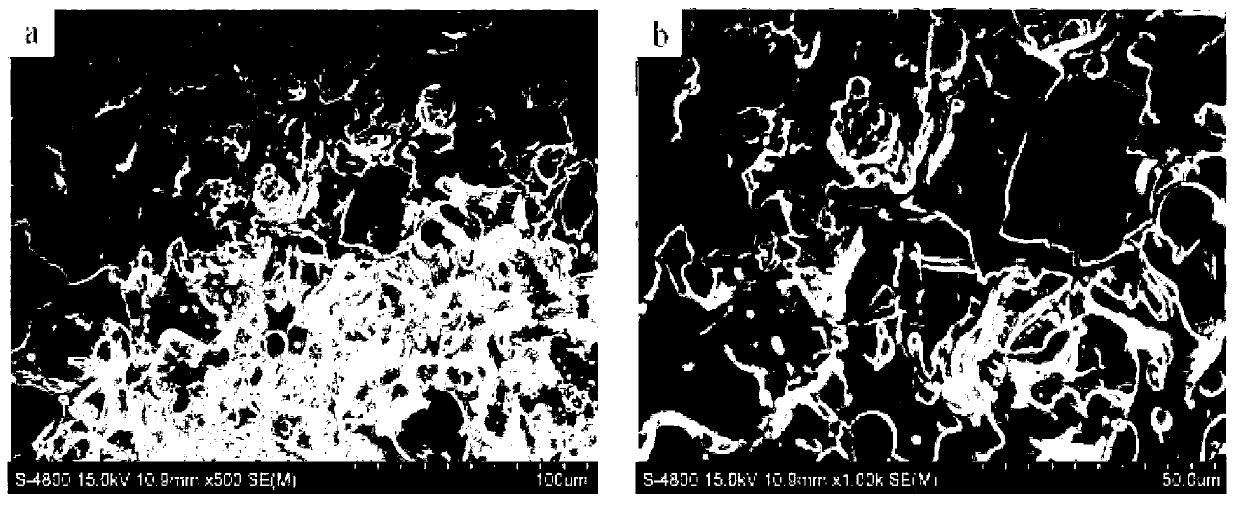

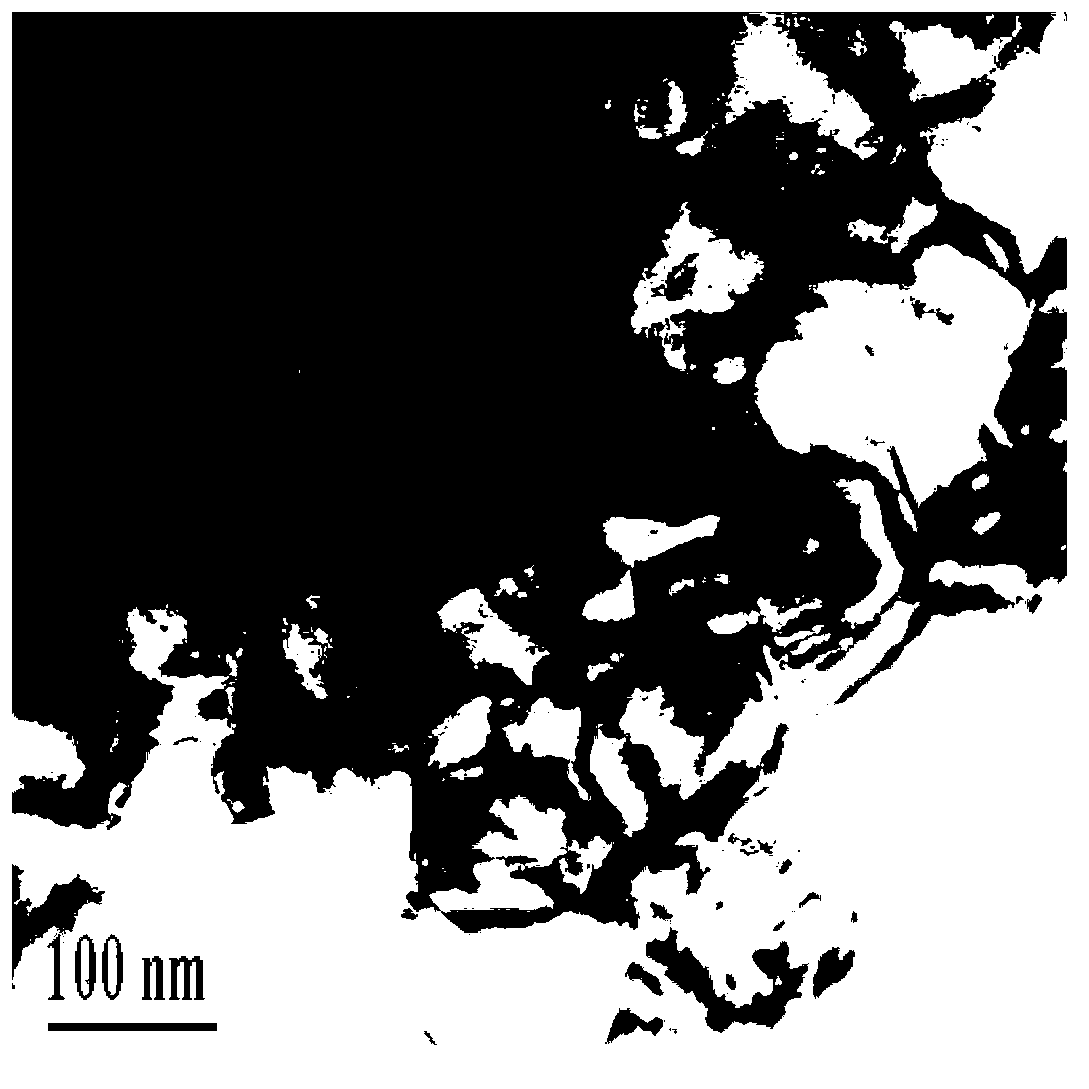

[0032] Example 1 - Ti / TiN / Sb-SnO 2 Compound electrode

[0033] (1) Take a 3mm thick Ti plate with a grade of TA1 as the substrate, and perform sandblasting (corundum) treatment with a dry sandblasting machine to remove surface oil and roughen the surface, with a roughness of Rz25-100μm.

[0034] (2) The substrate after sandblasting is placed on the plasma spraying operation table, using 80KWGP-80 plasma spraying equipment, BT-1 spray gun, and nickel-aluminum alloy powder is added to the powder feeder (see Table 1 for composition, particle size 30-60μm powder), open the spraying control cabinet, and spray a 40μm thick nickel-clad aluminum alloy bonded bottom layer. The spraying process parameters are power 20KW, ion Ar gas 65L / min, ion N 2 Gas 50L / min, spraying distance 120mm, powder feeding N 2 Gas 10L / min.

[0035] The composition of the sprayed nickel aluminum and gold powder in Table 1

[0036]

[0037] (3) The powder in the powder feeder is replaced by micron metal...

Embodiment 2

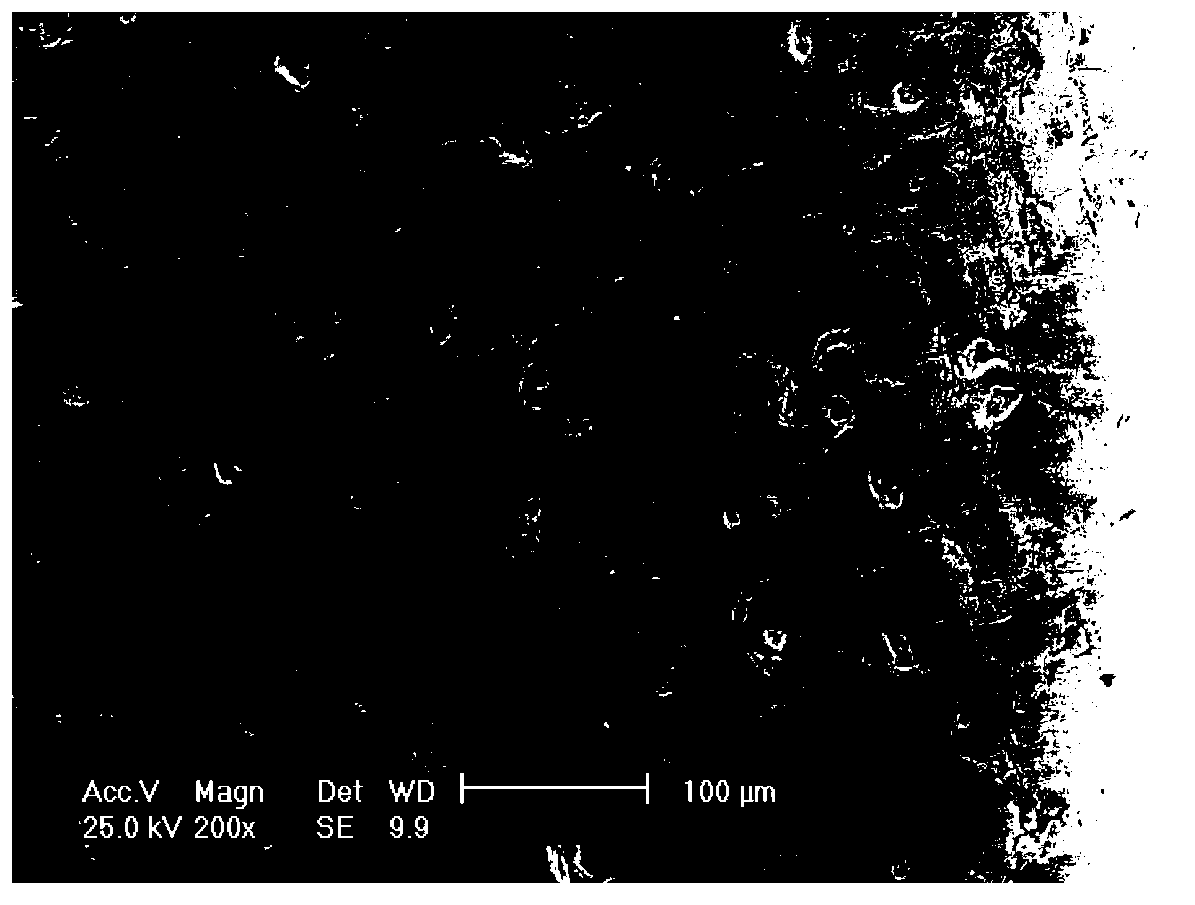

[0046] Example 2 - Fe(Q235) / TiN / PbO 2 Compound electrode

[0047] (1) Take 3mm thick Q235 steel (carbon content 0.05-0.038wt.%) as the substrate, clean the oil on the surface of the substrate, and perform sandblasting.

[0048] (2) The substrate after sandblasting is placed on the plasma spraying operation table, nickel-aluminum alloy powder (95%Ni+5%aluminum, particle size 30-60μm) is added to the powder feeder, the spraying control cabinet is opened, and 70μm thick nickel is sprayed. The base layer is bonded with aluminum alloy. Spraying process parameters: power 25KW, ion Ar gas 70L / min, ion N 2 Gas 60L / min, spraying distance 120mm, powder feeding N 2 Gas 8L / min.

[0049] (3) The powder in the powder feeder is replaced with micron metal Ti powder, and the TiN intermediate layer is prepared by spraying grade Ti. The spraying process parameters are spraying power 28KW, ion Ar gas 70L / min, ion N 2 Gas 90L / min, spraying distance 110mm, powder feeding N 2 Gas 10L / min, the ...

Embodiment 3

[0054] (1) Same as embodiment 2

[0055] (2) The substrate after sandblasting is placed on the plasma spraying operation table, and iron-aluminum alloy powder (containing Fe50wt.%, the rest is Al, particle size 30-60μm) is added to the powder feeder, and the spraying control cabinet is opened to spray 50μm thick Iron-aluminum alloy powder bonds the bottom layer. Spraying process parameters: power 28KW, ion Ar gas 75L / min, ion N 2 Gas 70L / min, spraying distance 110mm, powder feeding N 2 Gas 8L / min.

[0056] (3)~(5) Same as embodiment 2

[0057] The oxygen evolution potential of the obtained composite electrode is 0.4V higher than that of the electrode without the TiN interlayer, and the strengthened life of the electrode is 120 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Oxygen evolution potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com