Responsivity-enhanced ZnO-based photoconductive detector and preparation method thereof

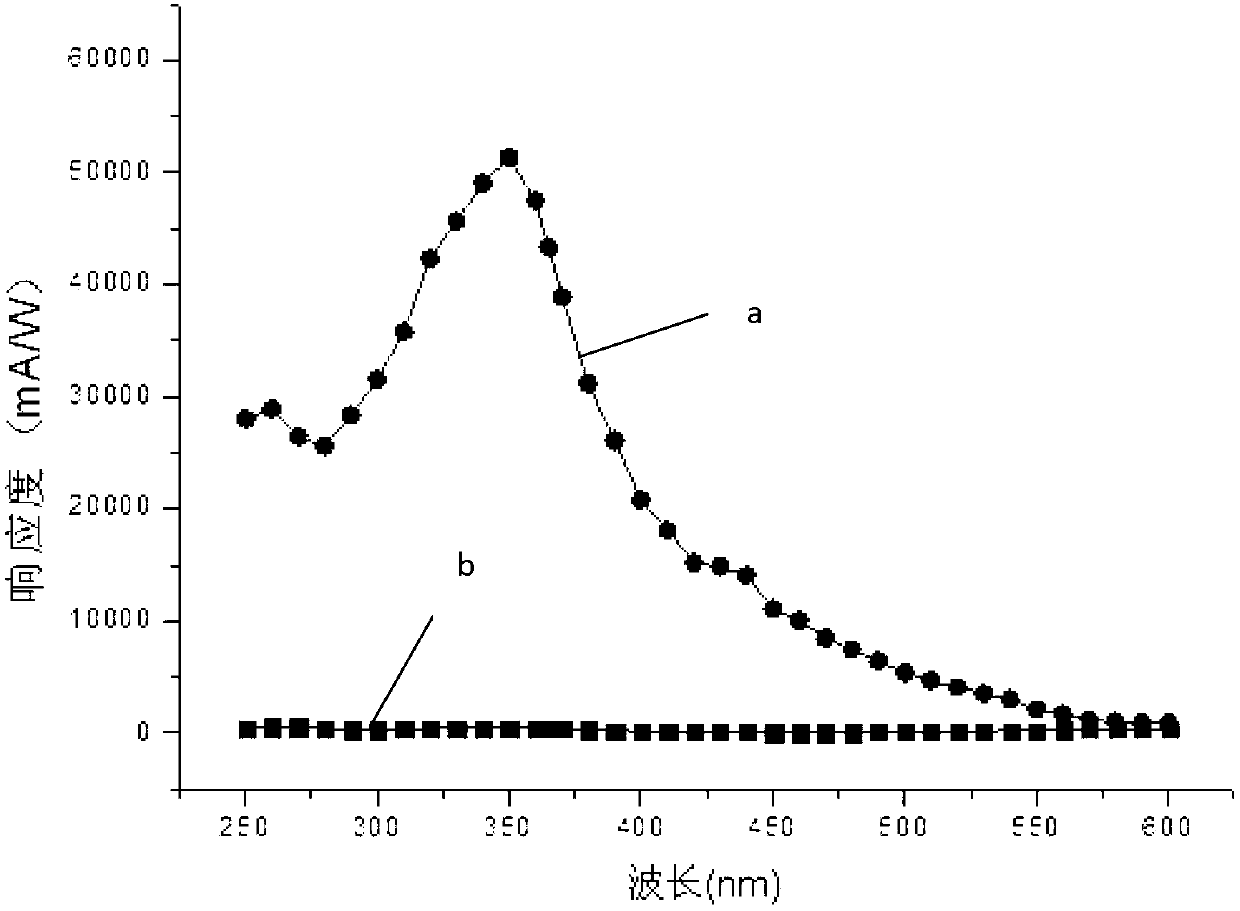

A photoconductive and enhanced technology, applied in the direction of semiconductor devices, circuits, electrical components, etc., can solve the problems of weak ultraviolet signal and low photoresponsivity, and achieve the effect of simple manufacturing process and improved photoresponsivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

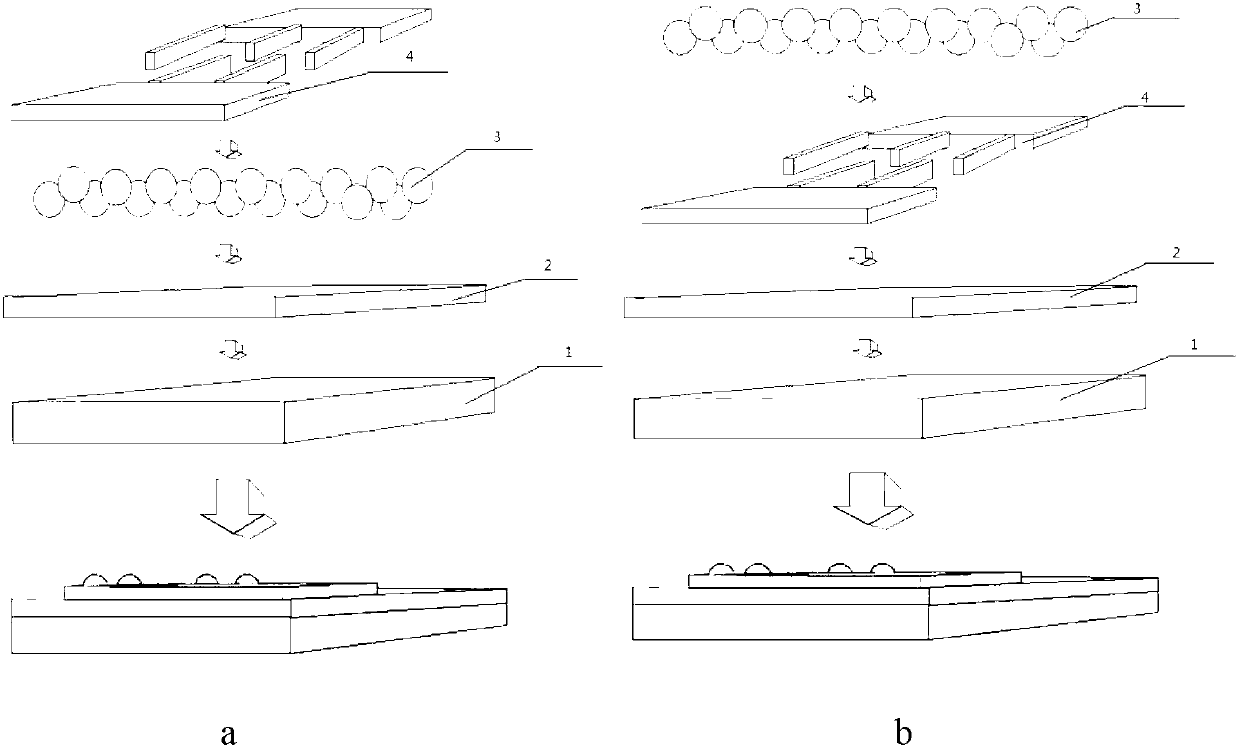

[0031] see figure 1 a, the method for preparing the response-enhanced ZnO-based photoconductive detector of the first structure of the present invention comprises the following steps:

[0032] 1) Clean the substrate 1, put it into the magnetron sputtering system, and evacuate the vacuum chamber to 8×10 -4 Below Pa, heat the substrate 1 to 200-400°C at the same time, and then feed argon and oxygen at the same time, so that the pressure of the vacuum chamber is 0.8-1.2Pa; then start to grow the ZnO thin film as the active layer with ZnO as the target material 2; Wherein, the volume flow ratio of argon gas and oxygen gas introduced is 25sccm: 35sccm, and the sputtering power is 70W when growing the ZnO thin film 2, and the time is 1.5 hours;

[0033] 2) Disperse Ag nanoparticles with a diameter of 50-150nm in deionized water to obtain an Ag nanoparticle dispersion; apply the Ag nanoparticle dispersion on the surface of the ZnO thin film 2 grown in step 1) with a spin coater, and...

Embodiment 1

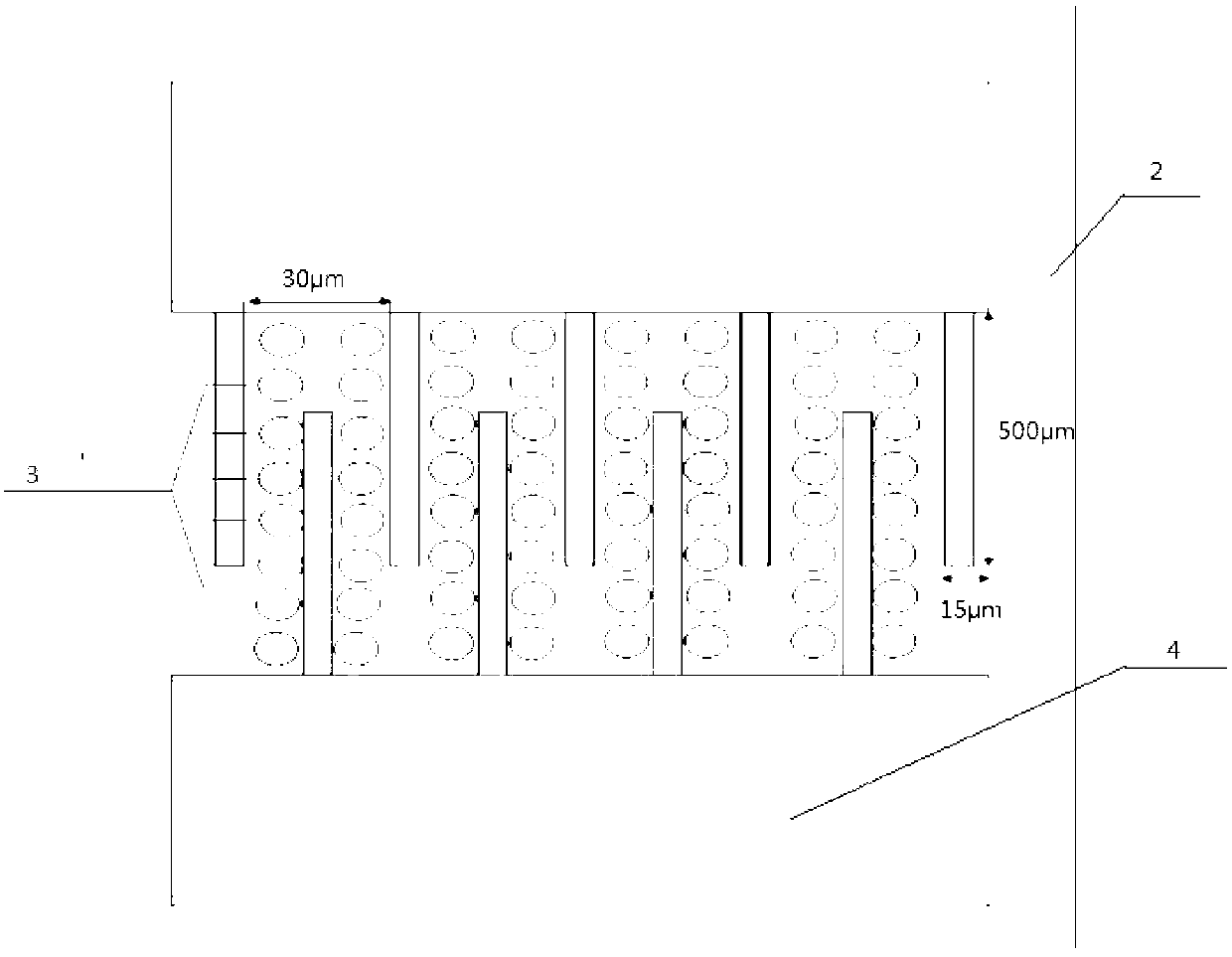

[0046] see figure 1 a, the first structure of the response-enhanced ZnO-based photoconductive detector of the present invention includes a quartz substrate and a ZnO film 2 disposed on the quartz substrate, and the ZnO film 2 is spin-coated with Ag nanoparticles 3, and the Ag nanoparticles Interdigitated Al electrodes 4 are also deposited on the interdigitated Al electrodes 4 , and part of the Ag nanoparticles 3 are exposed between adjacent fingers of the interdigitated Al electrodes 4 .

[0047] Among them, the thickness of the ZnO thin film 2 is 400nm; the diameter of the Ag nanoparticles is 100nm; the Ag nanoparticles 3 are spherical; The length is 500 μm and the interdigital width is 15 μm.

[0048] The preparation method of the response-enhanced ZnO-based photoconductive detector of this embodiment includes the following steps:

[0049] 1) Clean the quartz substrate, put it into the magnetron sputtering system, and evacuate the vacuum chamber to 5×10 -4 Pa, at the same...

Embodiment 2

[0055] see figure 1 b, the response-enhanced ZnO-based photoconductive detector of the present invention includes a quartz substrate and a ZnO thin film 2 disposed on the quartz substrate. An interdigitated Al electrode 4 is deposited on the ZnO thin film 2. On the interdigitated Al electrode 4 Ag nanoparticles 3 are filled between adjacent fingers, and the Ag nanoparticles 3 are spin-coated on the ZnO thin film 2 .

[0056] Among them, the thickness of the ZnO thin film 2 is 400nm; the Ag nanoparticles 3 are spherical; the height of the interdigitated Al electrode 4 is 150nm, the distance between adjacent interdigital fingers of the interdigitated Al electrode is 20 μm, the length of the interdigitated Al electrodes is 500 μm, and the width of the interdigitated Al electrodes is 500 μm. is 10 μm.

[0057] The preparation method of the response-enhanced ZnO-based photoconductive detector of this embodiment includes the following steps:

[0058] 1) Clean the quartz substrate,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com