Silver-loaded nanometer titanium dioxide photocatalyst and preparation method thereof

A nano-titanium dioxide, titanium dioxide technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the problem of low catalytic activity, small specific surface area, and low natural light absorption efficiency. and other problems, to achieve the effect of high light absorption capacity, large specific surface area, and good visible light response performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

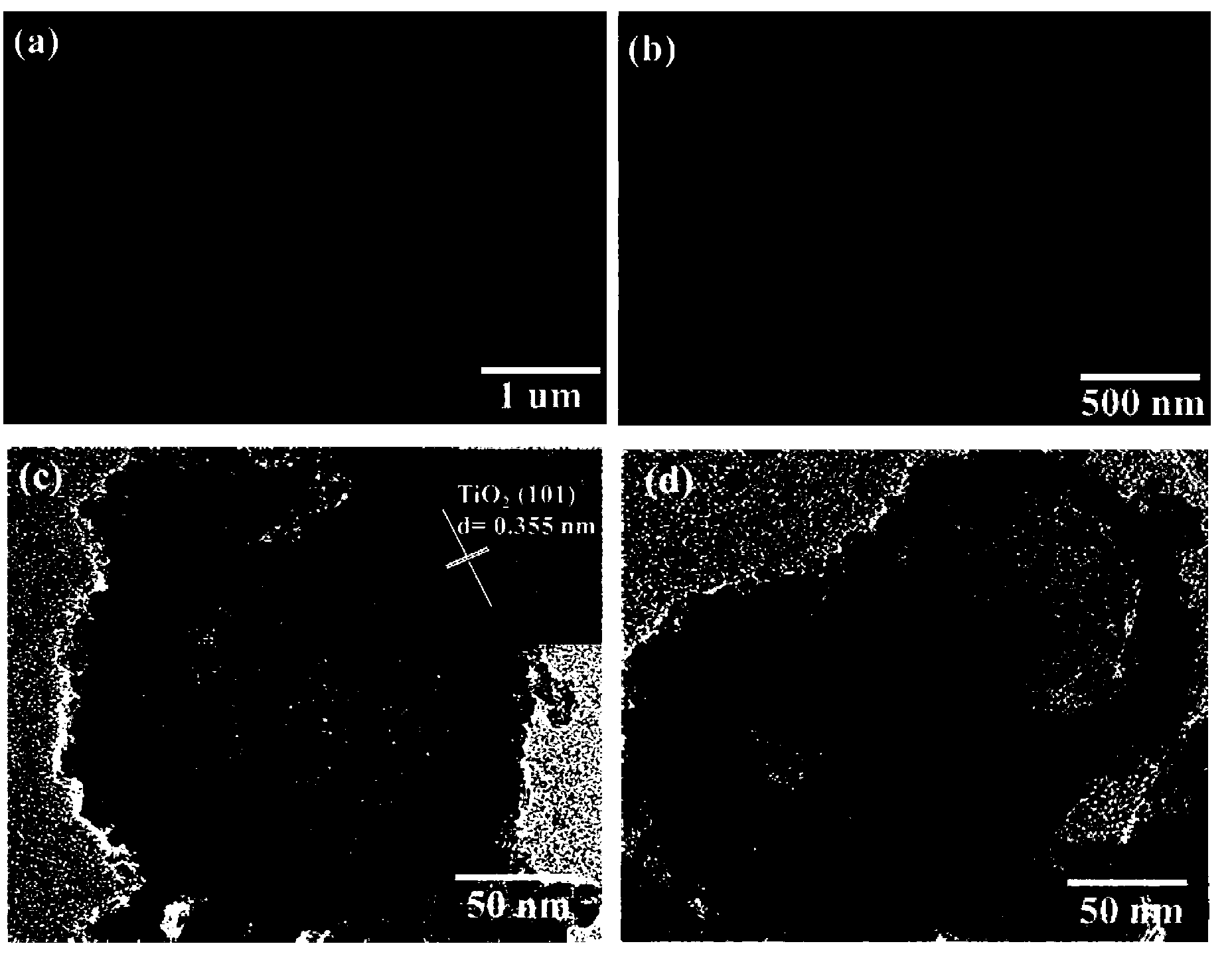

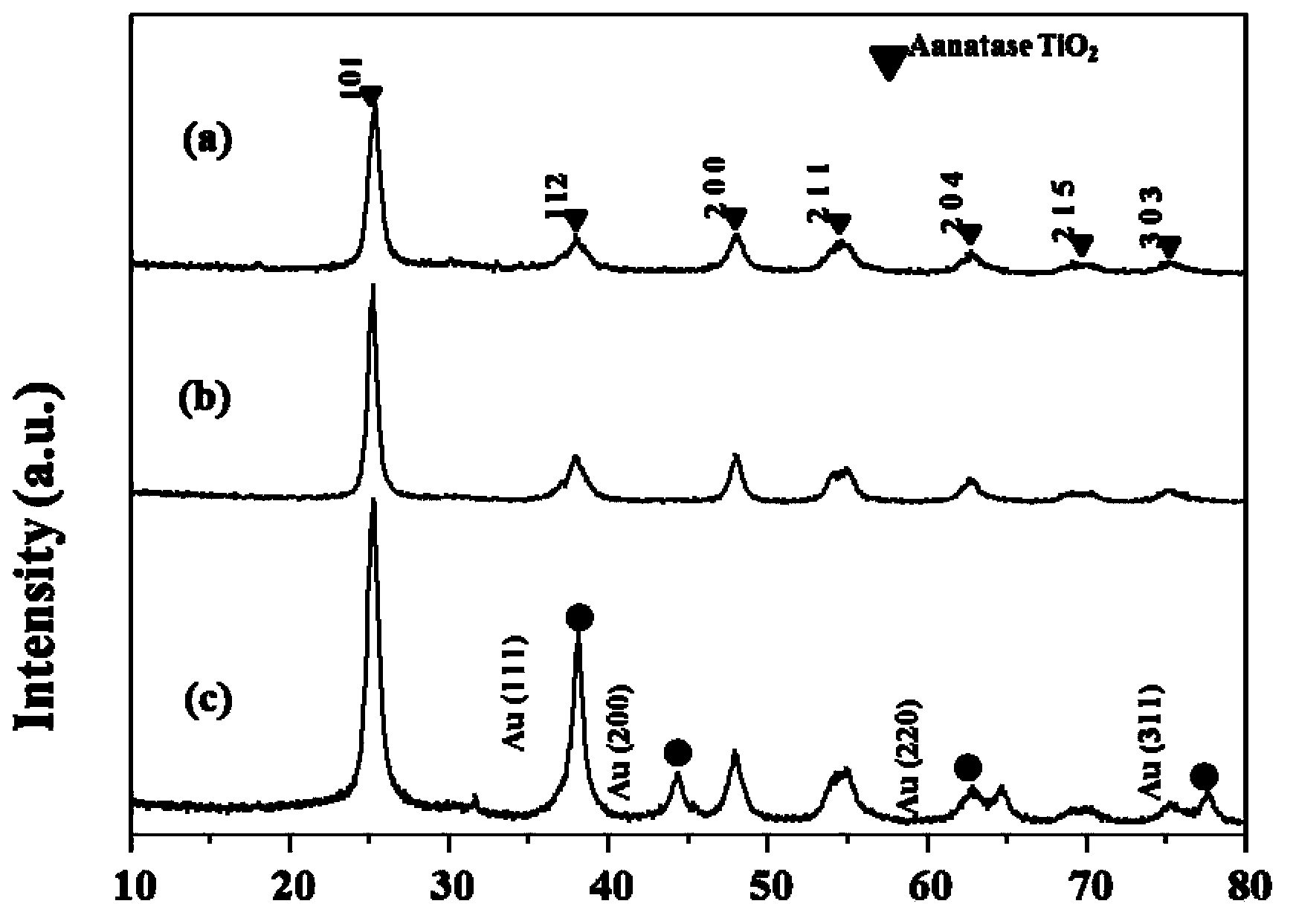

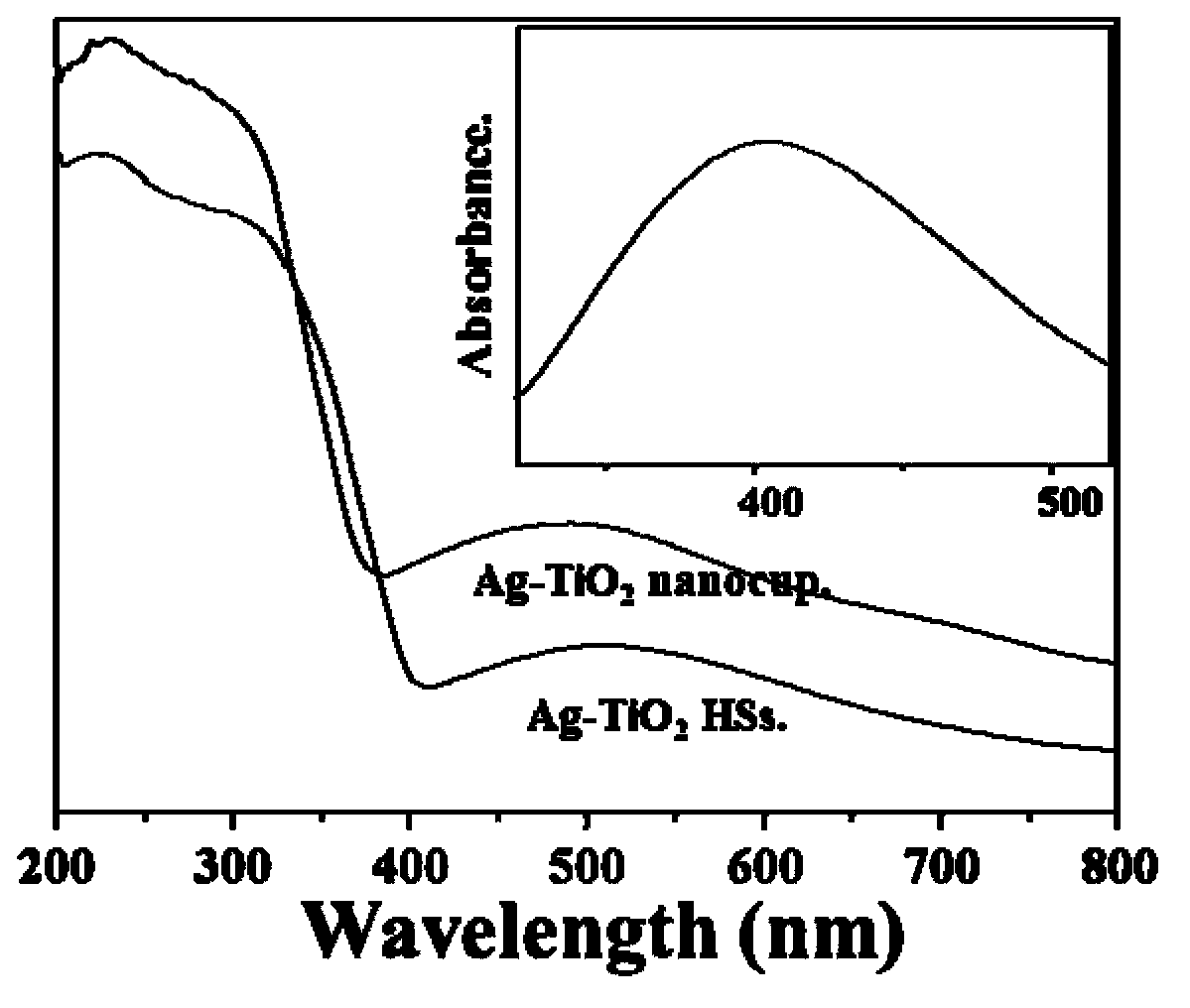

Image

Examples

Embodiment 1

[0027] (1) Weigh 1:0.8 parts by volume of tetraethyl orthosilicate and ammonia water, dissolve in a mixed solution of 6 parts by volume of deionized water and 36 parts by volume of ethanol, stir the solution for 4 hours until the hydrolysis is complete, and then centrifuge. Obtain solid silicon dioxide;

[0028] (2) ultrasonically disperse the solid silica obtained in step (1) into 5ml of ethanol solution;

[0029] (3) Dissolve hydroxypropyl cellulose in 20ml of ethanol, mix with the silicon dioxide ethanol solution obtained in step (2), and stir evenly;

[0030] (4) adjusting the pH value of the ethanol mixture of hydroxypropyl cellulose and silicon dioxide in step (3) to 6-9 with ammonia water;

[0031] (5) at 0.5mL·min -1 Add 1ml of tetrabutyl titanate dropwise to the mixed solution obtained in step (4) at the speed of 1, stir evenly, recirculate at 85°C, cool to room temperature naturally, centrifuge, wash, and dry to obtain silica / titania nuclei shell photocatalyst;

...

Embodiment 2

[0039] (1) Weigh 1:0.8 parts by volume of tetraethyl orthosilicate and ammonia water, dissolve in a mixed solution of 6 parts by volume of deionized water and 36 parts by volume of ethanol, stir the solution for 4 hours until the hydrolysis is complete, and then centrifuge. Obtain solid silicon dioxide;

[0040] (2) ultrasonically disperse the solid silica obtained in step (1) into 5ml of ethanol solution;

[0041] (3) Dissolve hydroxypropyl cellulose in 20ml of ethanol, mix with the silicon dioxide ethanol solution obtained in step (2), and stir evenly;

[0042] (4) adjusting the pH value of the ethanol mixture of hydroxypropyl cellulose and silicon dioxide in step (3) to 6-9 with ammonia water;

[0043] (5) at 2mL·min -1Add 1ml of tetrabutyl titanate dropwise to the mixture obtained in step (4) at the speed of 100°C, stir evenly, recirculate at 65°C, cool naturally to room temperature, centrifuge, wash, and dry to obtain silica / titania nuclei shell photocatalyst;

[0044...

Embodiment 3

[0049] (1) Weigh 1:0.8 parts by volume of tetraethyl orthosilicate and ammonia water, dissolve in a mixed solution of 6 parts by volume of deionized water and 36 parts by volume of ethanol, stir the solution for 4 hours until the hydrolysis is complete, and then centrifuge. Obtain solid silicon dioxide;

[0050] (2) ultrasonically disperse the solid silica obtained in step (1) into 5ml of ethanol solution;

[0051] (3) Dissolve hydroxypropyl cellulose in 20ml of ethanol, mix with the silicon dioxide ethanol solution obtained in step (2), and stir evenly;

[0052] (4) adjusting the pH value of the ethanol mixture of hydroxypropyl cellulose and silicon dioxide in step (3) to 6-9 with ammonia water;

[0053] (5) at 3mL·min -1 Add 1ml of tetrabutyl titanate dropwise to the mixed solution obtained in step (4) at the speed of 1, stir evenly, recirculate at 60°C, cool naturally to room temperature, centrifuge, wash, and dry to obtain silica / titania nuclei shell photocatalyst;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com