A special precision extrusion system for polyvinylidene fluoride

A polyvinylidene fluoride, precise technology, applied in the field of plastic molding and processing, can solve the problems of affecting the quality of extruded products, large pressure fluctuations at the extrusion outlet, poor plasticizing effect, etc., to achieve good plasticization, small pressure fluctuations, extrusion a stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

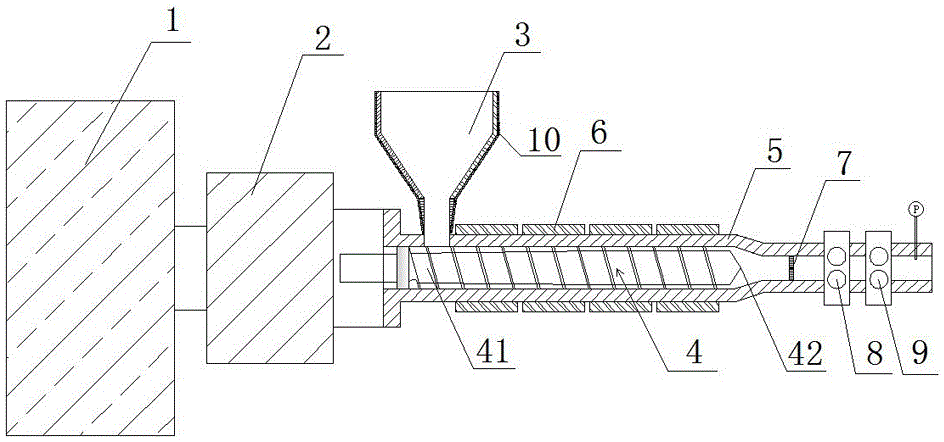

[0022] Such as figure 1 A special precision extrusion system for polyvinylidene fluoride is shown, including a motor 1, a gear box 2, a feeding hopper 3, a screw 4, a barrel 5, and a heating ring 6 installed on the barrel 5, and the heating ring is divided into 3 parts. - 7 independent heating zones, this embodiment adopts 4 independent heating zones, the heating temperature range of the barrel is 20-400°C; the motor 1 drives the screw 4 to rotate after the gear box 2 changes speed, and the screw 4 is installed with the barrel 5 Inside, and connected with the output shaft of the gearbox 2, the material of the screw is 38CrMoAlA alloy steel, the surface of the screw 4 is provided with a nitrided layer (processed by the existing technology), the thickness of the nitrided layer is 0.3mm, the long diameter of the screw The ratio is 36, and the screw compression ratio is 1.8. The feeding hopper 3 is installed on the barrel 5 at the root of the screw 41 and is connected to the feed...

Embodiment 2

[0025] The difference between this embodiment and Embodiment 1 is: the material of the screw rod 4 is Hastelloy alloy, the surface of the screw rod 4 has no nitrided layer, the length-to-diameter ratio of the screw rod is 28, and the compression ratio of the screw rod is 2.2; the mesh size of the filter screen 7 is At 350 mesh; the displacement of the first melt pump 8 is 30% larger than that of the second melt pump 9.

[0026] Other structures of this embodiment are the same as those of Embodiment 1.

[0027] Specific application implementation: The melt index of the PVDF raw material used is 6.8g / 10min (230°C, 5Kg); the feeding hopper is heated to 60°C, and the PVDF passes through the screw, filter screen, two-stage melt pump (the first melt pump and The second melt pump) after extrusion, the experiment shows that: PVDF plasticizing effect is good, the surface of the extrudate is smooth and shiny, and the pressure fluctuation range of the extrusion outlet is ±0.02MPa.

Embodiment 3

[0029] The difference between this embodiment and Embodiment 1 is that the thickness of the nitrided layer is 0.5mm, the length-to-diameter ratio of the screw is 32, and the compression ratio of the screw is 2.0; the mesh size of the filter screen 7 is 300 mesh; the first melt pump 8 The displacement is 20% larger than that of the second melt pump 9 .

[0030] Other technical features of this embodiment are the same as those of Embodiment 1.

[0031] Specific application implementation: The melt index of the PVDF raw material used is 6.8g / 10min (230°C, 5Kg); the feeding hopper is heated to 70°C, and PVDF passes through the screw, filter screen, two-stage melt pump (the first melt pump and The second melt pump) after extrusion, the experiment shows that: PVDF has good plasticizing effect, the surface of the extruded product is smooth and shiny, and the pressure fluctuation range of the extrusion outlet is ±0.01MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com