Plastic binder and preparation method thereof

A technology of adhesives and plastics, which is applied in the direction of adhesive types, hydrocarbon copolymer adhesives, non-polymer adhesive additives, etc., and can solve problems such as poor storage performance, low bonding strength, and narrow application range, etc. Problems, to achieve the effect of fast bonding, high bonding strength and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

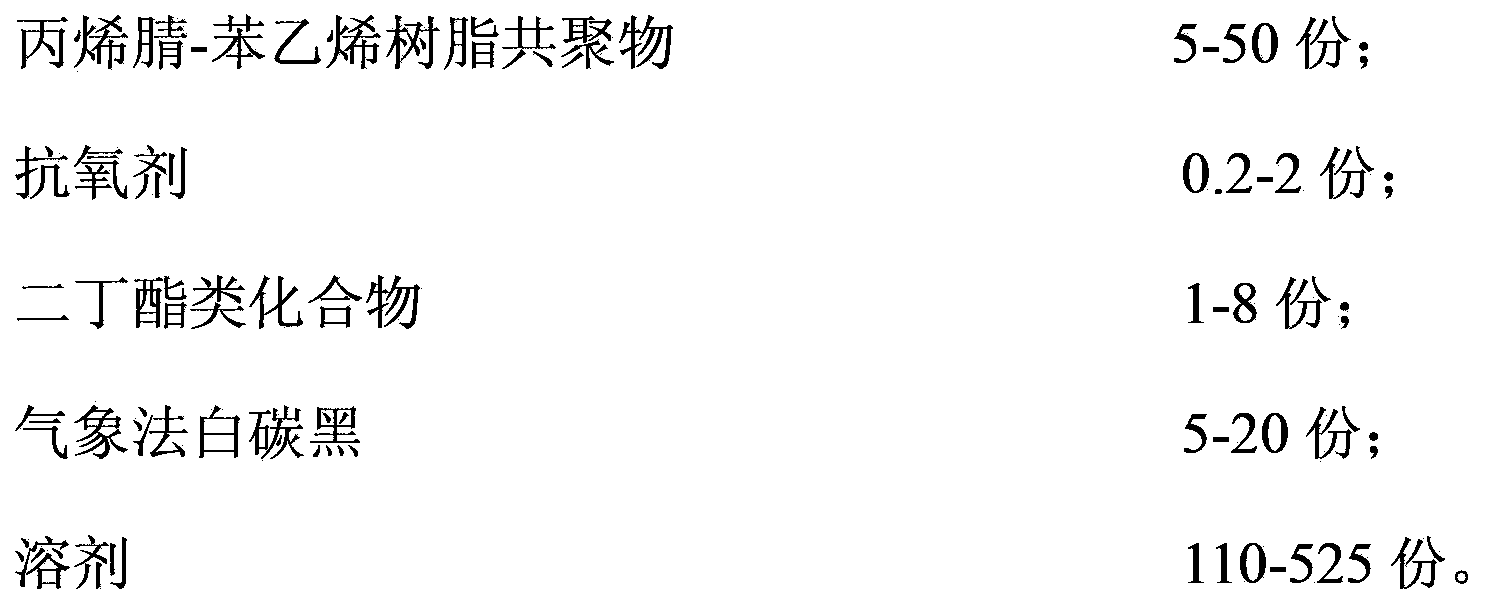

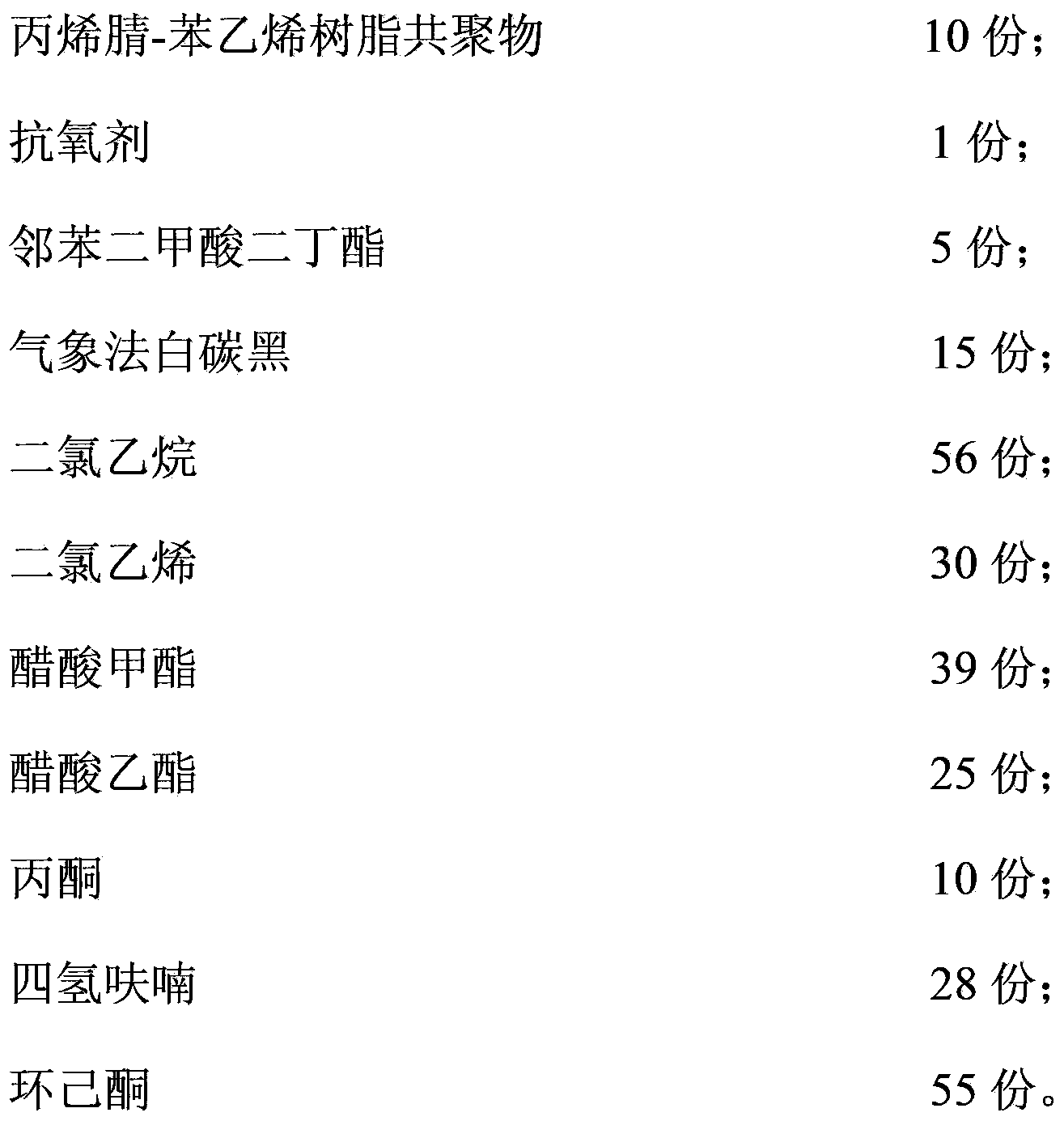

[0026] A plastic adhesive, based on the number of raw materials, the content of each component is:

[0027]

[0028] The base material is commercially pure acrylonitrile-styrene resin copolymer.

[0029] The antioxidant is tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester and silane coupling agent. The quality of tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid]pentaerythritol ester is 50% of the antioxidant quality. The mass of the silane coupling agent is 50% of the mass of the antioxidant.

[0030] The preparation method comprises the following steps:

[0031] A. Take dichloroethane, dichloroethylene, methyl acetate, ethyl acetate, acetone, tetrahydrofuran and cyclohexanone by weight respectively and join in the reactor, drop into 15 parts of meteorological method white carbon black, stir, Obtain solution one;

[0032] B. In solution one, drop into 10 parts of industrial pure acrylonitrile-styrene resin copolymer, stir, obta...

Embodiment 2

[0036] A plastic adhesive, based on the number of raw materials, the content of each component is:

[0037]

[0038] The base material is commercially pure acrylonitrile-styrene resin copolymer.

[0039] The antioxidant is tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester and silane coupling agent. The quality of tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid]pentaerythritol ester is 50% of the antioxidant quality. The mass of the silane coupling agent is 50% of the mass of the antioxidant.

[0040] The preparation method comprises the following steps:

[0041] A. Take dichloroethane, dichloroethylene, methyl acetate, ethyl acetate, acetone, tetrahydrofuran and cyclohexanone by weight respectively and join in the reactor, drop into 20 parts of meteorological white carbon black, stir, Obtain solution one;

[0042] B. In solution one, drop into 50 parts of industrial pure acrylonitrile-styrene resin copolymers, stir, obtain sol...

Embodiment 3

[0046] A plastic adhesive, based on the number of raw materials, the content of each component is:

[0047]

[0048] The base material is commercially pure acrylonitrile-styrene resin copolymer.

[0049]The antioxidant is tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester and silane coupling agent. The quality of tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid]pentaerythritol ester is 50% of the antioxidant quality. The mass of the silane coupling agent is 50% of the mass of the antioxidant.

[0050] The preparation method comprises the following steps:

[0051] A. Take dichloroethane, dichloroethylene, methyl acetate, ethyl acetate, acetone, tetrahydrofuran and cyclohexanone by weight respectively and join in the reactor, drop into 5 parts of meteorological method white carbon black, stir, Obtain solution one;

[0052] B. In solution one, drop into 10 parts of industrial pure acrylonitrile-styrene resin copolymer, stir, obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com