Method for separating and recovering V and Cr from V-Cr waste material

A waste material, vanadium chromium technology, applied in the field of chromium and vanadium recovery, separation of vanadium and chromium, can solve the problems of vanadium and chromium separation and recovery without practical significance, incomplete separation, complicated operation, etc., to facilitate the promotion and implementation of industrialization and facilitate the process The effect of simplification of operation and process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

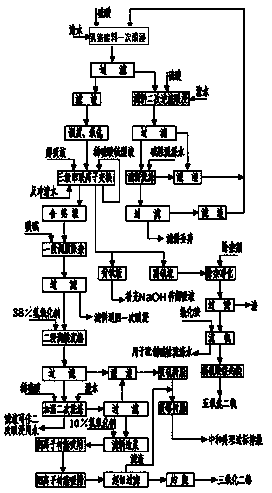

Image

Examples

Embodiment 1

[0042] Weigh 50g vanadium chromium waste (containing V 2 o 5 5.41%, including Cr 2 o 3 5.78%), add water according to the solid-liquid ratio of 1:5, stir with a magnetic stirrer, add sulfuric acid in total 14mL while stirring, the pH value of the material liquid is close to 1.5, continue to stir for 1 hour and use a vacuum pump to filter; filter cake according to the solid-liquid ratio of 1 : 5 add water and stir for 1 hour, filter with vacuum pump, combine filtrate, filtrate volume 454mL (wherein: V 2 o 5 Concentration 4.81g / L, Cr 2 o 3 Concentration 5.65g / L), adjusted to pH 2.5 with liquid caustic soda. The filter cake is subjected to the second-stage pickling solution, and water is added according to the solid-to-liquid ratio of the raw materials at 1:5. After adding sulfuric acid solution while stirring, the pH value of the solution is stabilized at 0.5, and then continue to stir for 1 hour, filter with a vacuum pump, and store the filtrate. The filter cake was stir...

Embodiment 2

[0044] Take by weighing 50 grams of vanadium-chromium waste (containing V 2 o 5 5.41%, including Cr 2 o 3 5.78%), according to the solid-to-liquid ratio of 1:5 after adding the second-stage acid dipping solution of Example 1 and replenishing clear water. Add sulfuric acid while stirring until the pH value of the solution is stable at 1.5, continue to stir for 1 hour, filter with a vacuum pump, add the washing solution of the second-stage acid leaching of Example 1 to the filter cake, and add clear water to a solid-to-liquid ratio of 1:5, and stir for 1 hour. hour, vacuum pump suction filtration, the filter cake is subjected to two-stage acid leaching, and water is added according to the solid-to-liquid ratio of 1:5, and sulfuric acid is added while stirring until the pH value is 0.5, and the stirring is continued for 1 hour. Add water at 1:4, stir and wash for 1 hour, then use vacuum pump to filter; filter cake drying test: vanadium (V 2 o 5 Total) 0.17%, containing chro...

Embodiment 3

[0047] a), take by weighing 1.2 tons of vanadium-chromium waste, after testing this material contains vanadium (V 2 o 5 Total) 5.52%, chromium (Cr 2 o 3 Total) 5.65%, put into the reactor.

[0048] b) After adding water according to the solid-to-liquid ratio of 1:5, add H while stirring 2 SO 4 Until the pH value of the solution is stable at 1.5, continue stirring for 1 hour, filter with a plate and frame filter press, and store the filtrate in a pool.

[0049] The filter cakes obtained in steps c), b) are respectively returned to the reaction kettle, added water and stirred for 1 hour according to the solid-to-liquid ratio of 1.2 tons of vanadium-chromium waste (the weight of the raw material is 1.2 tons), and then filtered with a plate and frame filter press, and the filtrate is stored, and the filter cake is still Return to the reactor.

[0050] d), add water to the filter cake obtained in step c) according to the raw material weight-solid-liquid ratio of 1:5, add sul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com