Anode oxidation and organic-dyeing electrophoresis process of aluminium alloy

Anodizing, aluminum alloy technology, applied in anodizing, electrolytic coating, surface reaction electrolytic coating, etc., to achieve the effect of good quality, low production cost, high acid and alkali resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

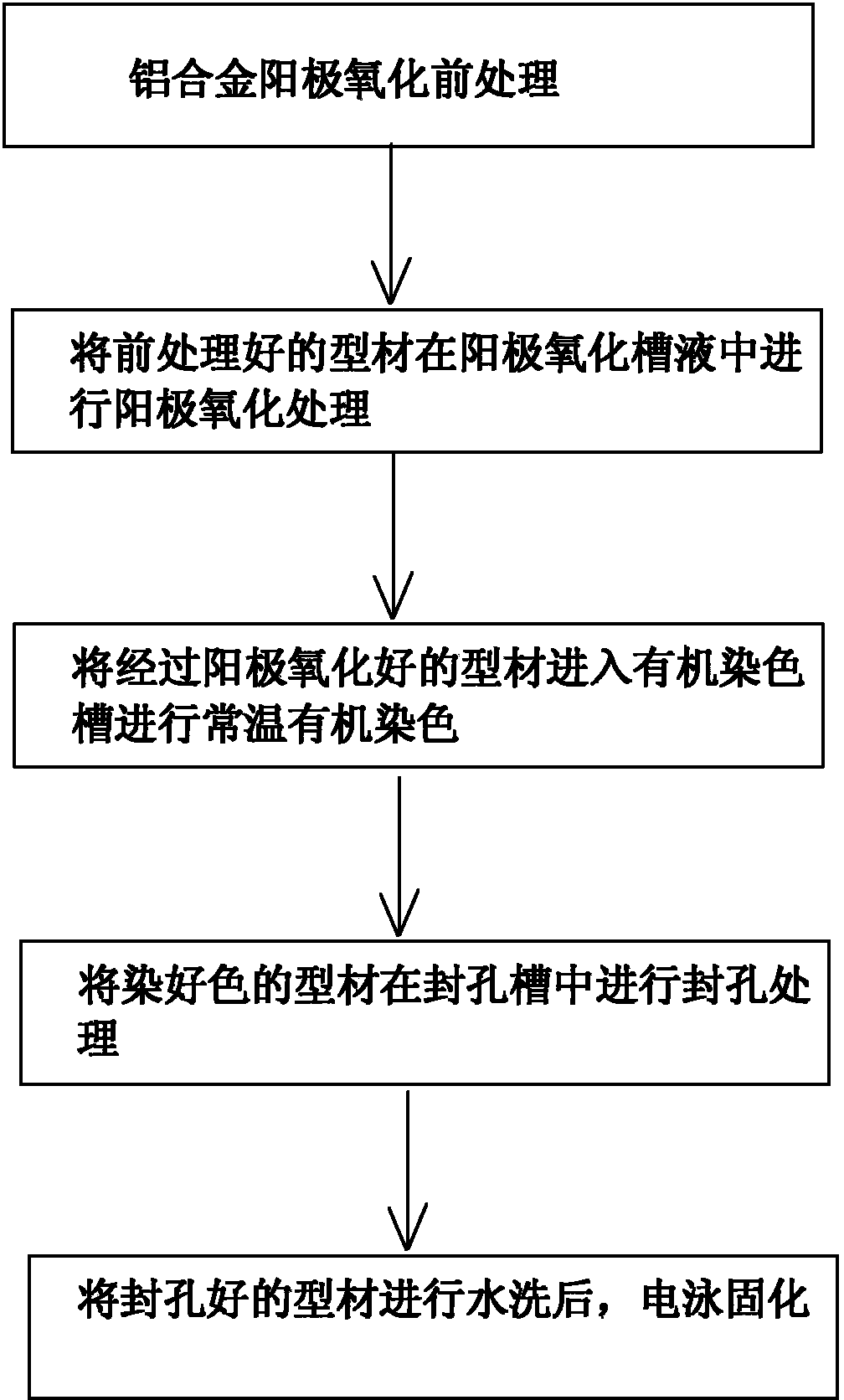

Method used

Image

Examples

Embodiment 1

[0032] Profile surface pre-treatment: Use brightener 90g / L to mix tank (phosphoric acid 50%, hydrofluoric acid 30%, surface active ion (fatty acid polyoxyethylene ether) 5%), etch at room temperature for 3 minutes, then use caustic soda 45g / L to mix The tank was etched for 3 minutes, and then neutralized with 185g / L bath solution for 3 minutes to obtain a bright aluminum alloy active surface superior to traditional pretreatment. The pre-treated aluminum profile is immersed in anodic oxidation, sulfuric acid 180 g / L, temperature: 21 ° C, oxidation time 28 minutes, current density 1.3 A / dm2, and a colorless and transparent anodic oxidation film is obtained.

[0033] After washing with water three times, it enters the dyeing tank, organic purple gold dye is 5g / L, and the dyeing time is 2 minutes under the environment of normal temperature and pH value of 5.5, and the dyed aluminum profile is obtained, which is designated as purple gold 1# color. After washing twice with water, it...

Embodiment 2

[0036] Profile surface pre-treatment: Use brightener 90g / L to mix tank (phosphoric acid 50%, hydrofluoric acid 30%, surface active ion (fatty acid polyoxyethylene ether) 5%), etch at room temperature for 3 minutes, then use caustic soda 45g / L to mix The tank was etched for 3 minutes, and then neutralized with 185g / L bath solution for 3 minutes to obtain a bright aluminum alloy active surface superior to traditional pretreatment. The pre-treated aluminum profile is immersed in anodic oxidation, sulfuric acid 180 g / L, temperature: 21 ° C, oxidation time 28 minutes, current density 1.3 A / dm2, and a colorless and transparent anodic oxidation film is obtained.

[0037] After washing with water three times, enter the dyeing tank, organic rose bengal dye 4g / L, dyeing time is 2 minutes under the environment of normal temperature and pH value of 5.5, and obtain the dyed aluminum profile, which is designated as rose red. After washing twice with water, it enters the sealing tank. The ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com