Method for preparing magnetic tunnel junction (MTJ) nano column array

A technology of nano-column array and bottom electrode, which is applied in the field of micro-nano electronics, can solve the problems of large experimental error and cumbersome and complicated preparation process, and achieve reduced experimental error, good etching resistance, and omission of coating and stripping processes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

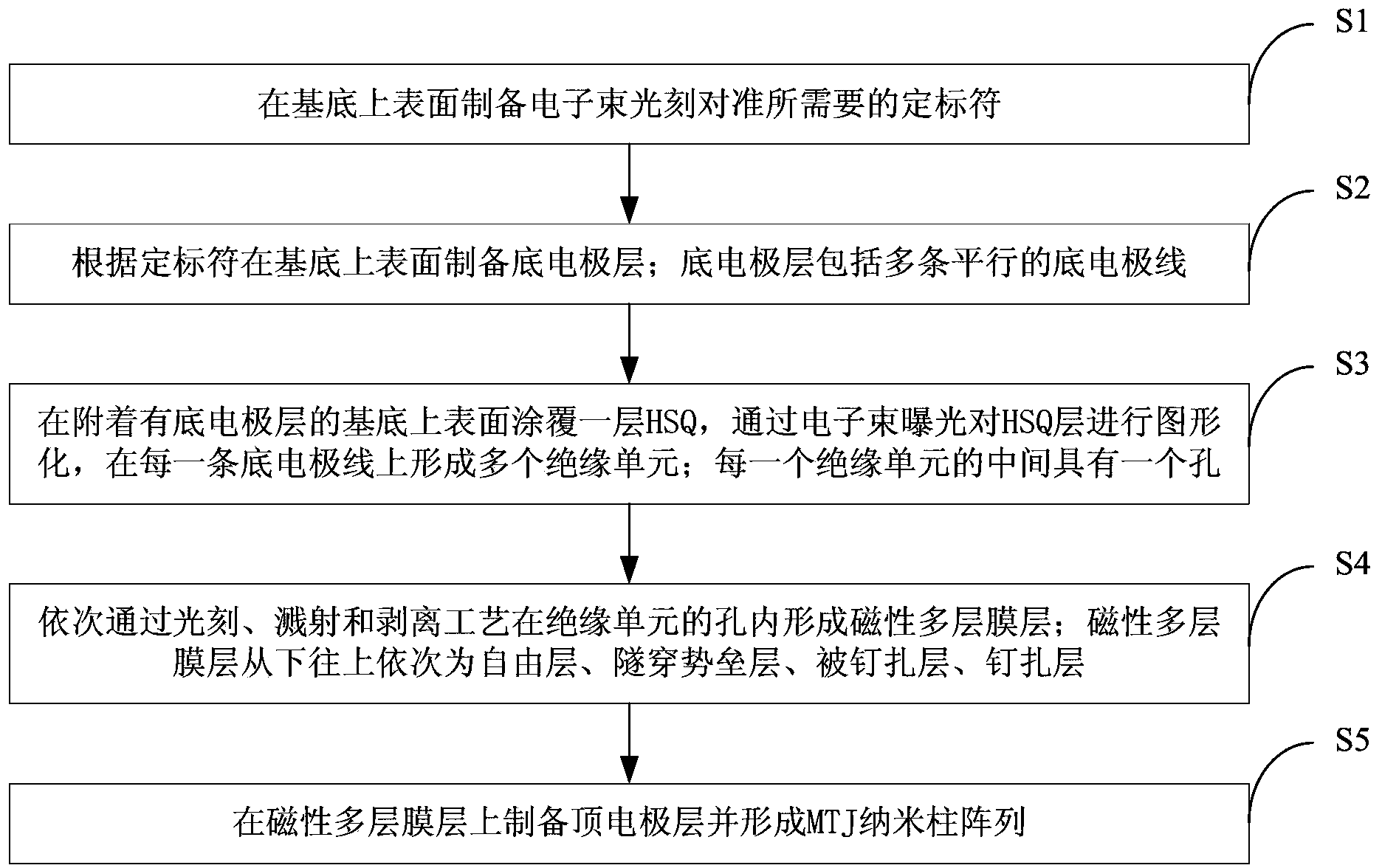

[0033] Such as figure 1 with figure 2 As shown, the preparation method of the MTJ nanocolumn array provided by the invention mainly includes the following steps:

[0034] S1: Prepare the calibration marks 12 required for electron beam lithography alignment on the upper surface of the substrate 1 by means of electron beam exposure, evaporation and stripping;

[0035] The scale marks can be multiple cross-shaped heavy metal marks, which play a vital role in the precise positioning of the device during the "overlay" process of several electron beam exposures; generally, there are 4 scale marks located on the substrate the four corners of the surface.

[0036]S2: Prepare the bottom electrode layer 3 on the upper surface of the substrate 1 according to the scale symbol 12. The bottom electrode layer 3 includes N parallel bottom electrode lines; the value of N is determined by the number of MTJ nanocolumns that have been set.

[0037] S3: Coating a layer of HSQ photoresist 13 on...

Embodiment 1

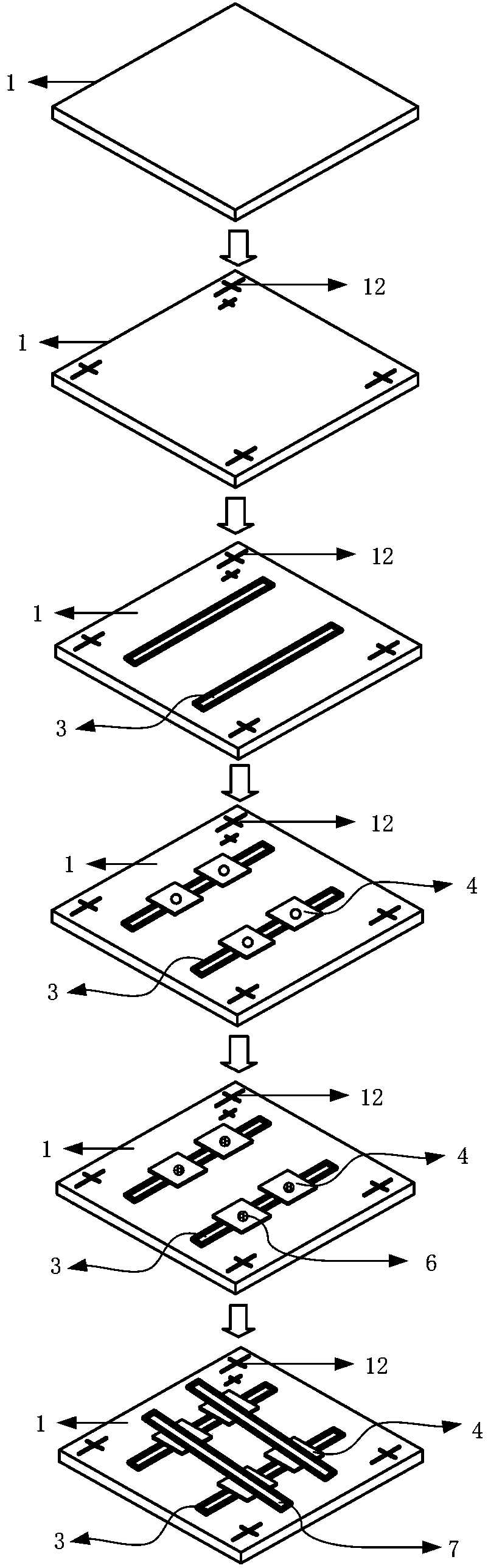

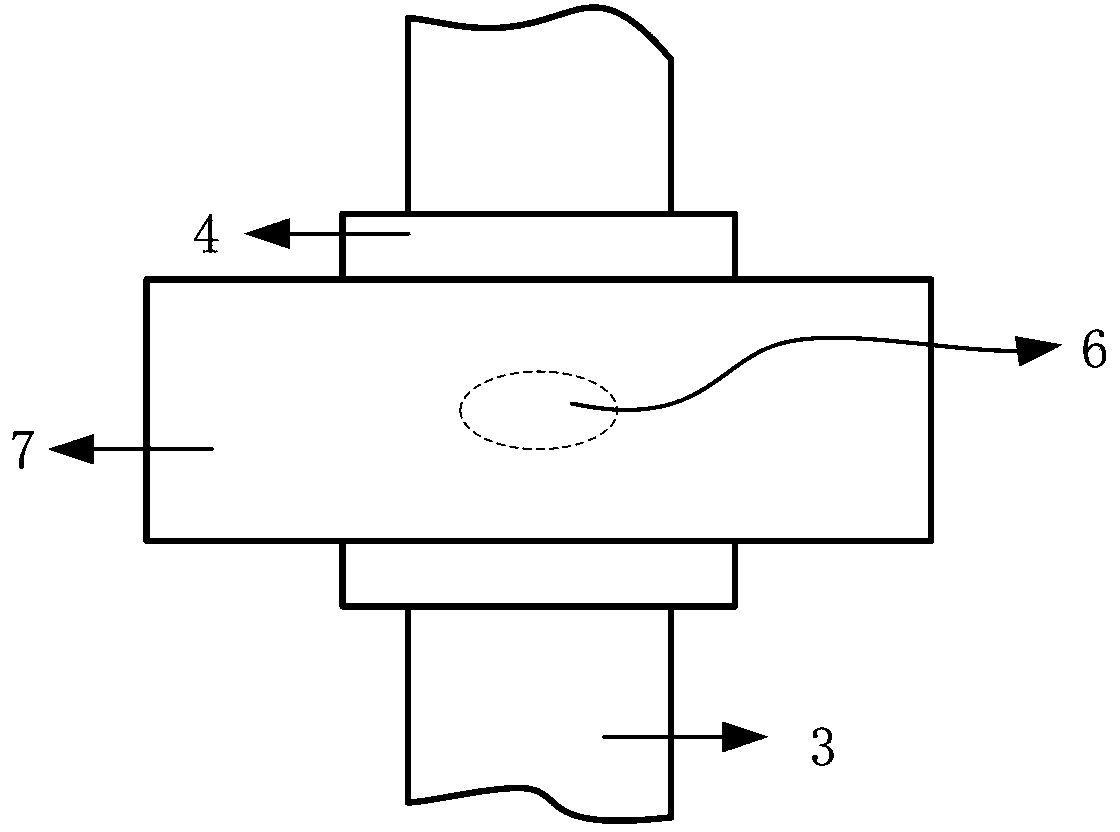

[0050] figure 2 The preparation process flow of MTJ nanocolumn array in embodiment 1 is shown, image 3 with Figure 4 They are a top view and a cross-sectional view of an MTJ nanocolumn in Example 1, respectively. refer to figure 2 , image 3 with Figure 4 The MTJ nanocolumn array in Embodiment 1 of the present invention includes a substrate 1 , a scale 12 , a bottom electrode layer 3 , an insulating unit 4 , a magnetic multilayer film layer 6 and a top electrode layer 7 . refer to Figure 5 , The magnetic multilayer film layer 6 includes a free layer 8 , a tunneling barrier layer 9 , a pinned layer 10 , and a pinned layer 11 from bottom to top.

[0051] Wherein, the base 1 is an insulating substrate, such as a ceramic substrate, a glass substrate, a resin substrate, a quartz substrate, and the like. The size and thickness of the substrate 1 are not limited, and those skilled in the art can select according to needs. In this embodiment, the material of the substrat...

Embodiment 2

[0108] Compared with Example 1, the coating method of the bottom electrode layer and the top electrode layer is changed, and other steps remain unchanged. Both the bottom electrode layer and the top electrode layer are prepared by electron beam evaporation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com