Preparation method for monodisperse hollow silicon dioxide nanosphere with controllable size and shell thickness

A silicon dioxide, monodisperse technology, applied in the direction of silicon dioxide, silicon oxide, nanotechnology for materials and surface science, etc., can solve the problem of wide size distribution, wide size distribution of hollow silica nanospheres, The thickness of the shell layer is uncontrollable, etc., to achieve the effect of a simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

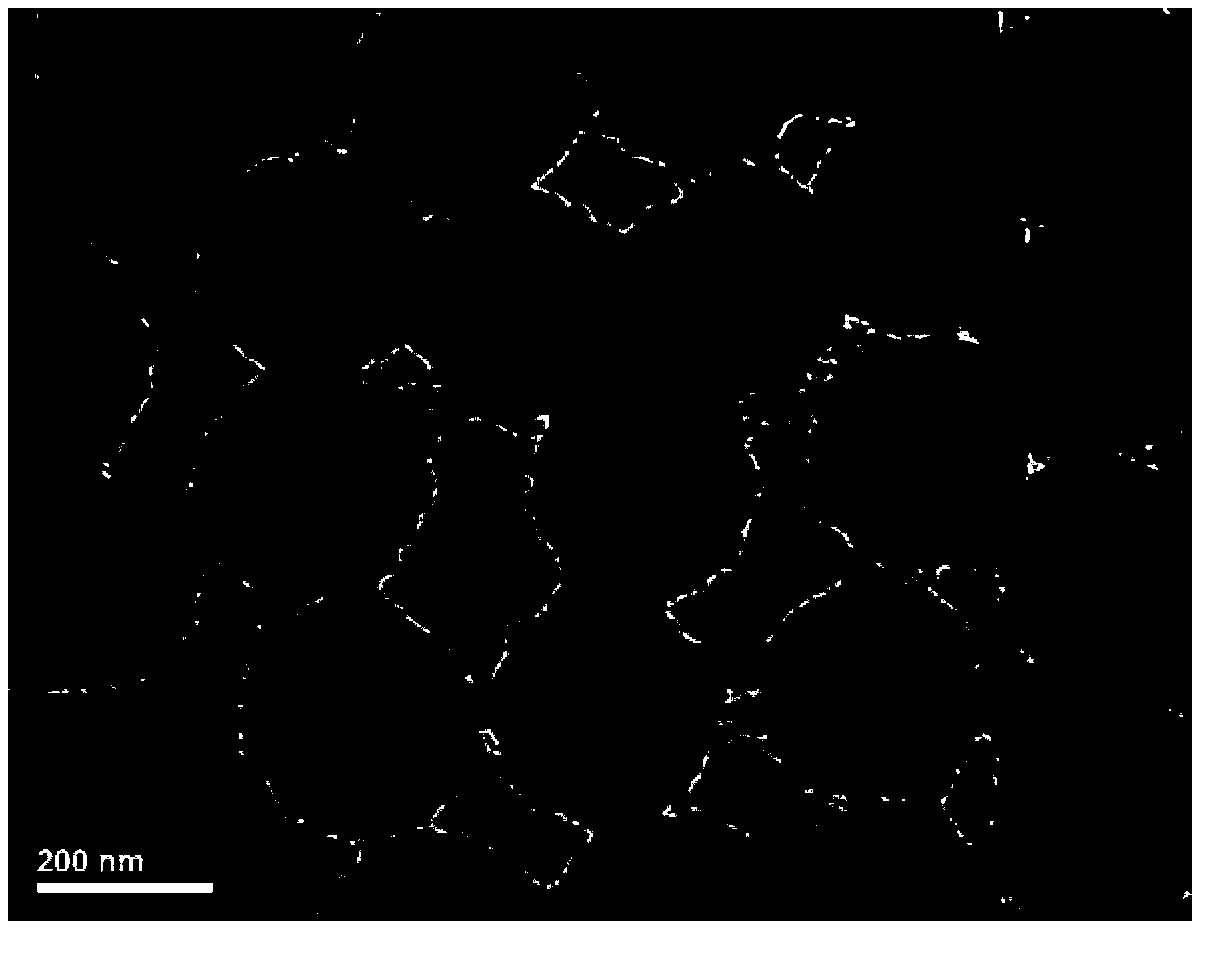

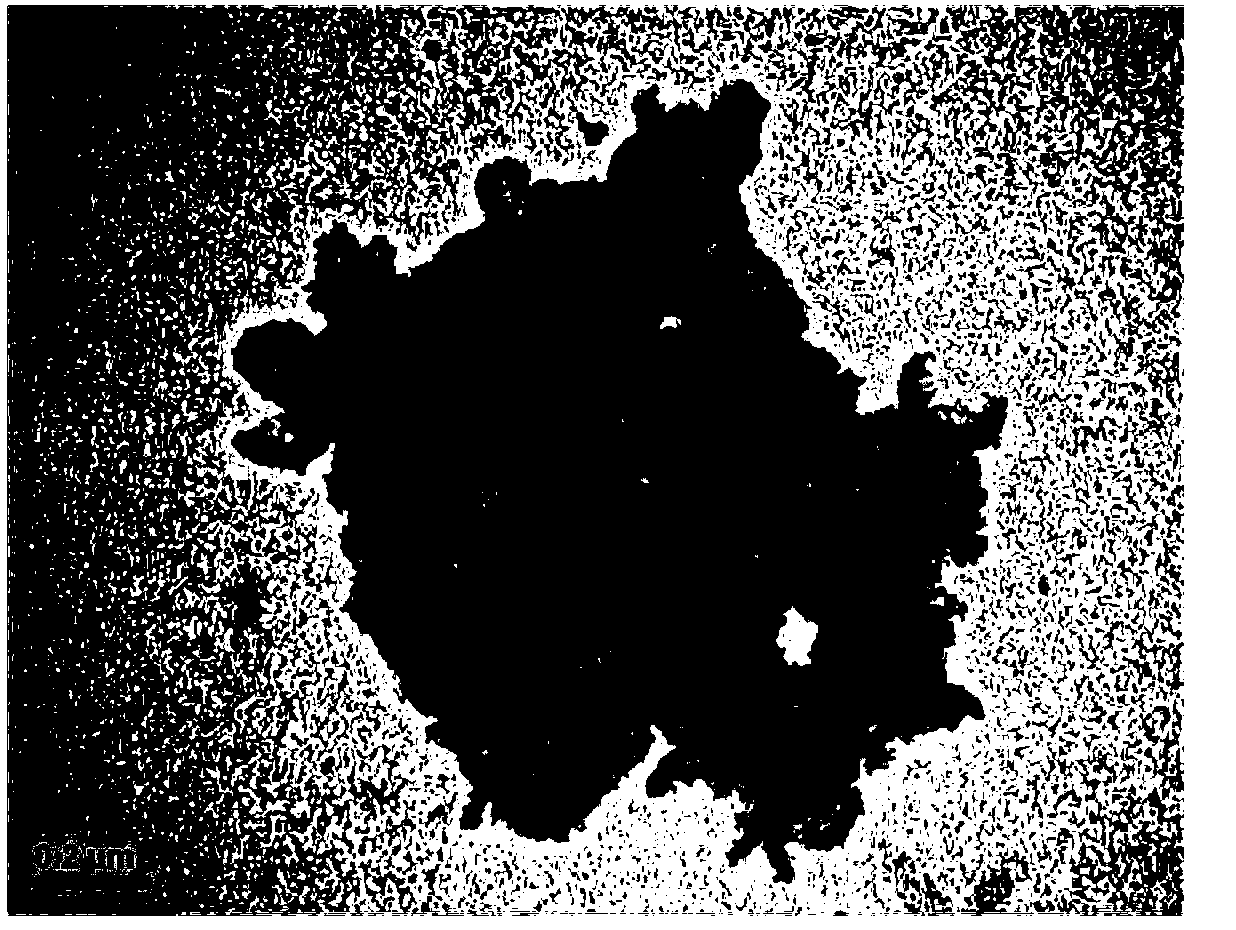

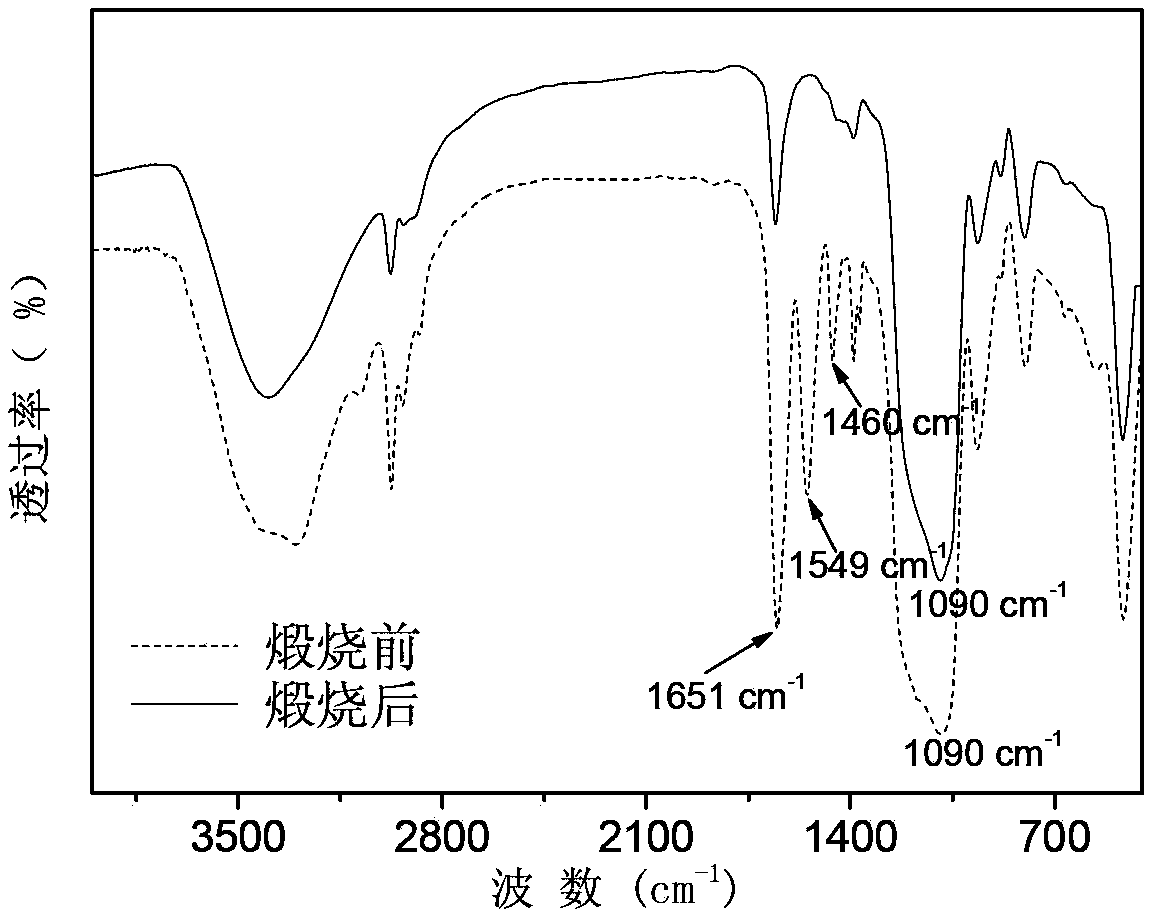

[0042] 250 mg of N-isopropylacrylamide monomer was dissolved in 48 ml of deionized water to obtain monomer aqueous solution I. 10 mg of ammonium persulfate was dissolved in 2 ml of deionized water to obtain aqueous initiator solution II. Under the condition of stirring, the monomer aqueous solution I was heated to 70° C., and nitrogen gas was used to remove oxygen for 30 minutes. Then, the initiator aqueous solution II was added to the monomer aqueous solution I to initiate a radical polymerization reaction for 6 hours to obtain an emulsion of poly-N-isopropylacrylamide, and after the reaction was completed, the temperature was lowered to 50° C. to obtain emulsion A. At 50°C, 2ml tetraethyl orthosilicate was added to 18ml for prehydrolysis for 3 hours to obtain solution B. The emulsion A was added to the solution B, and reacted at 50° C. for 72 hours to obtain monodisperse nanoparticles of poly-N-isopropylacrylamide coated with silicon dioxide.

[0043] Drop the obtained aqu...

Embodiment 2

[0045] Dissolve 50 mg of N-isopropylacrylamide monomer in 48 ml of deionized water to obtain monomer aqueous solution I. 10 mg of azobisisobutylamidine hydrochloride was dissolved in 2 ml of deionized water to obtain aqueous initiator solution II. Under the condition of stirring, the monomer aqueous solution I was heated to 65° C., and nitrogen gas was used to remove oxygen for 30 minutes. Then, the initiator aqueous solution II was added to the monomer aqueous solution I to initiate a radical polymerization reaction for 3 hours to obtain an emulsion of poly-N-isopropylacrylamide. After the reaction, the temperature was lowered to 40° C. to obtain emulsion A. At 40°C, 0.5ml tetraethyl orthosilicate was added to 18ml for prehydrolysis for 2 hours to obtain solution B. The emulsion A was added to the solution B, and reacted at 45° C. for 96 hours to obtain monodisperse nanoparticles of poly-N-isopropylacrylamide coated with silica. Calcining the monodisperse nanoparticles of p...

Embodiment 3

[0047] 250 mg of N-isopropylacrylamide monomer was dissolved in 48 ml of deionized water to obtain monomer aqueous solution I. 150 mg of azobisisobutylamidine hydrochloride was dissolved in 2 ml of deionized water to obtain aqueous initiator solution II. Under the condition of stirring, the monomer aqueous solution I was heated to 75° C., and nitrogen gas was used to remove oxygen for 30 minutes. Then, the initiator aqueous solution II was added to the monomer aqueous solution I to initiate a free radical polymerization reaction for 6 hours to obtain an emulsion of poly-N-isopropylacrylamide. After the reaction, the temperature was lowered to 60° C. to obtain emulsion A. At 60°C, 0.5ml tetraethyl orthosilicate was added to 12ml for prehydrolysis for 5 hours to obtain solution B. The emulsion A was added to the solution B, and reacted at 55° C. for 84 hours to obtain monodisperse nanoparticles of poly-N-isopropylacrylamide coated with silica. Calcining the monodisperse nanopa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com