Method for eliminating side product polysaccharide in fermentation production of pyrroloquinoline quinone, and application of method

A technology of pyrroloquinoline quinone and by-products, which is applied in the fields of microbial fermentation technology and genetic engineering, can solve problems such as methods and applications that have not been reported, and achieve the effects of reducing the synthesis level and simplifying the purification process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The acquisition of the flanking fragment of embodiment 1mpq_1844 gene and 5 ' end and 3 ' end and the construction of knockout plasmid

[0032]Enter mpq_1844 from the NCBI gene bank database (specific URL: http: / / www.ncbi.nlm.nih.gov / nuccore / NC_014733.1?from=1899875&to=1901296&report=fasta), download and save the gene sequence and 5' end and the flanking sequence at the 3' end; the nucleotide sequence of the mpq_1844 is shown in SEQ.ID No.1, and the nucleotide sequence of the flanking sequence is shown in SEQ.ID No.2 and SEQ.ID No.3. Genomic DNA of the PQQ production strain Methylovorus sp.MP688 was extracted using the Genome Extraction Kit (Tiangen Bacterial Genome Extraction Kit) as shown, and the 5' flanking sequence forward primer UpF was used as shown in SEQ.ID No.4 (ATT GGG CCT GCC GAT GGG CGC TGA CC) and reverse primer UpR as shown in SEQ.ID No.5 (CG GGA TCC GAGGCC CGT GGA GTC TGC), 3' flanking sequence forward primer DwF as shown in SEQ.ID No.6 Shown (GG ACT AG...

Embodiment 2

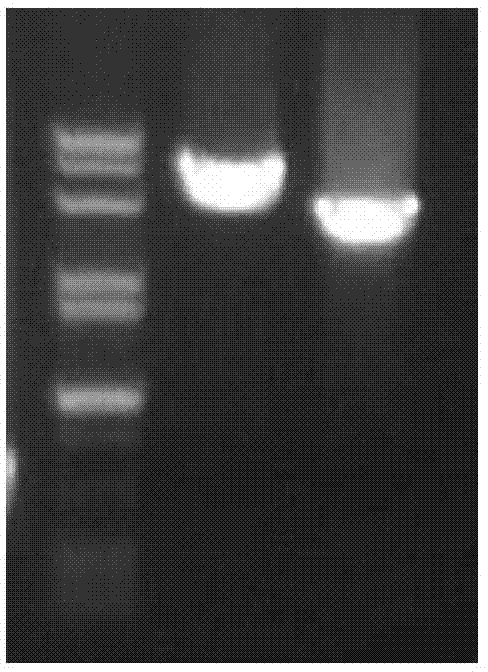

[0042] Example 2 Knockout of mpq_1844 gene and its identification

[0043] The knockout plasmid obtained in Example 1 was introduced into the PQQ production strain Methylovorus sp.MP688 by conventional electroporation or conjugative transfer, and the introduction conditions were referred to the document Magnetosome vesicles are present before magnetite formation, and MamA is required for their Activation, apply the reacted bacterial solution on the plate on the solid medium containing 50 μg / ml ampicillin MP, the composition of the MP solid medium is 1 liter containing MgSO 4 ·7H 2 O: 0.2g, (NH 4 ) 2 SO 4 : 3g, KH 2 PO 4 : 1.4g, Na 2 HPO 4 12H 2 O: 3g, Ferric Citrate: 30mg, CaCl 2 : 30mg; MnCl 2 4H 2 O: 5mg, ZnSO 4 ·7H 2 O: 5mg, CuSO 4 ·5H 2 O: 0.5mg, 1% agar powder. After culturing at 30°C for 2 days, randomly pick a single colony and inoculate it into a liquid medium without any screening pressure. The formula of the liquid medium is the same as above, without...

Embodiment 3

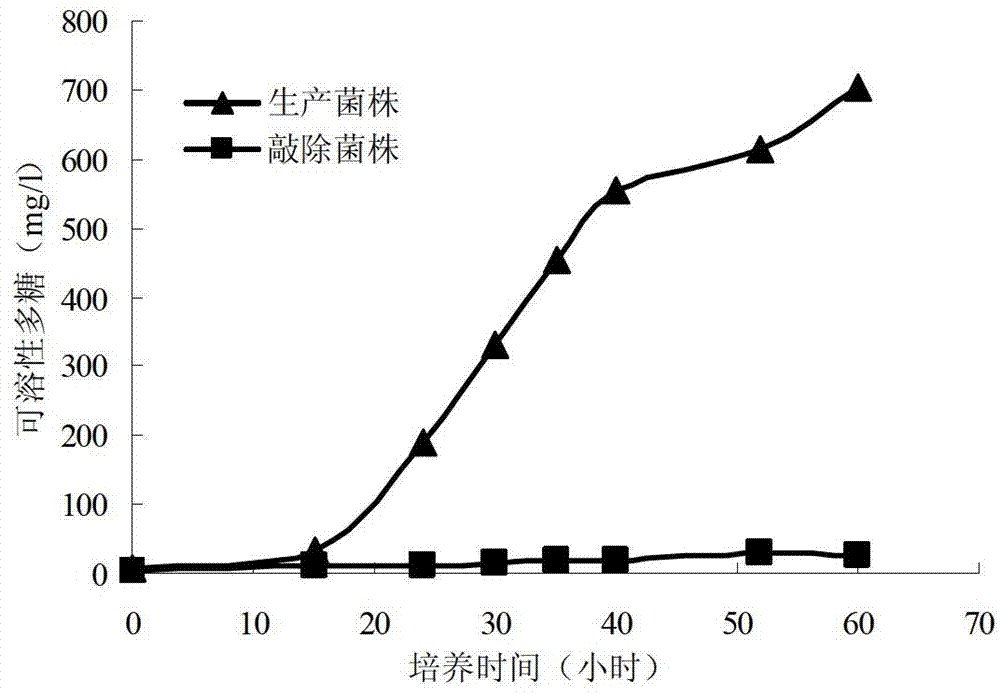

[0049] The mensuration of embodiment 3 exopolysaccharide and pyrroloquinoline quinone content

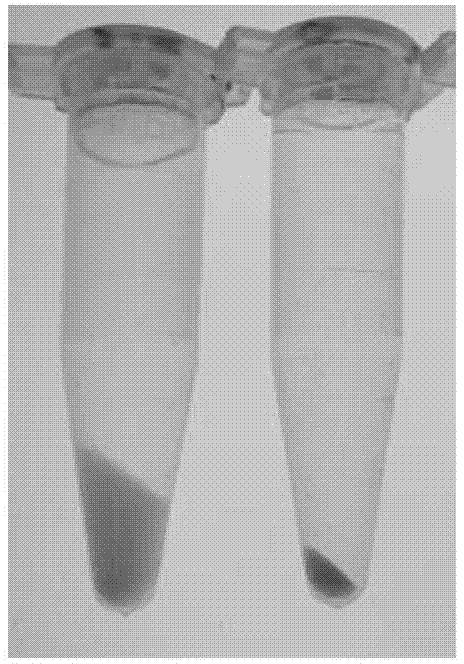

[0050] Inoculate the screened knockout strain and the original production strain into a 250ml Erlenmeyer flask containing 100ml of MP liquid medium (medium formula is the same as in Example 3, without adding agar powder), culture at 30°C, 200rpm, and follow the Dubois M The phenol-sulfuric acid method reported in the document Colorimetric method fordetermination of sugars and related substance in 1956 by et al. was used to measure the content of soluble polysaccharides. The content of polysaccharides measured in the fermentation broth of gene-deleted bacteria was below 10mg / l. It can be considered that there is no polysaccharides. The production strain 60 A polysaccharide content of 700mg / l was detected in the fermented liquid of 1 hour (see figure 2 ); the original production strain had flocs on the surface of the bacteria after centrifugation, while the gene deletion strain had n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com